Treatment method for copper concentrate leached residues

A treatment method and technology for leaching slag, applied in solid separation, flotation and other directions, can solve the problems of waste of copper resources, waste of leaching slag, etc., and achieve the effects of high recovery rate, reduction of leaching cost, and avoidance of waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

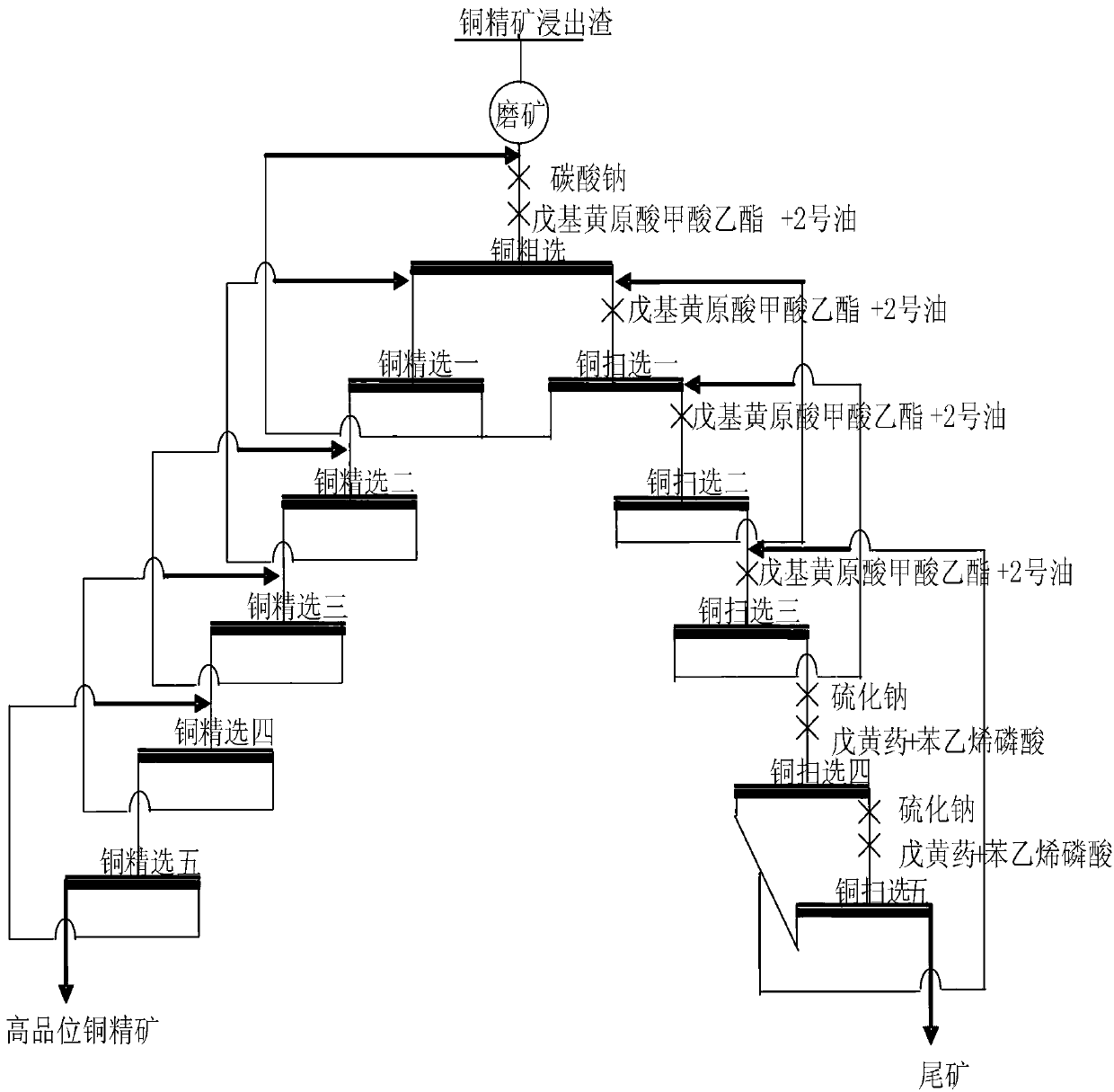

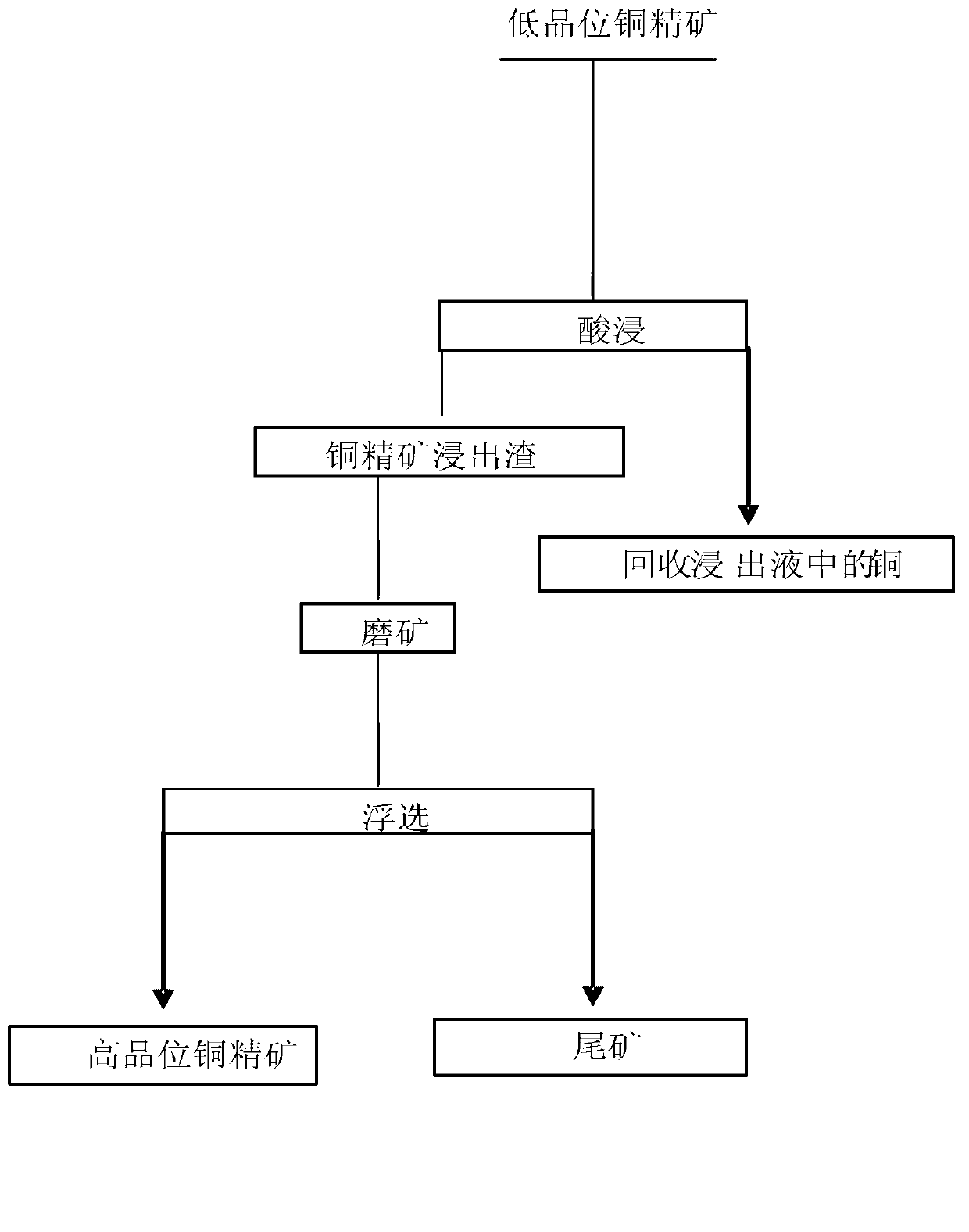

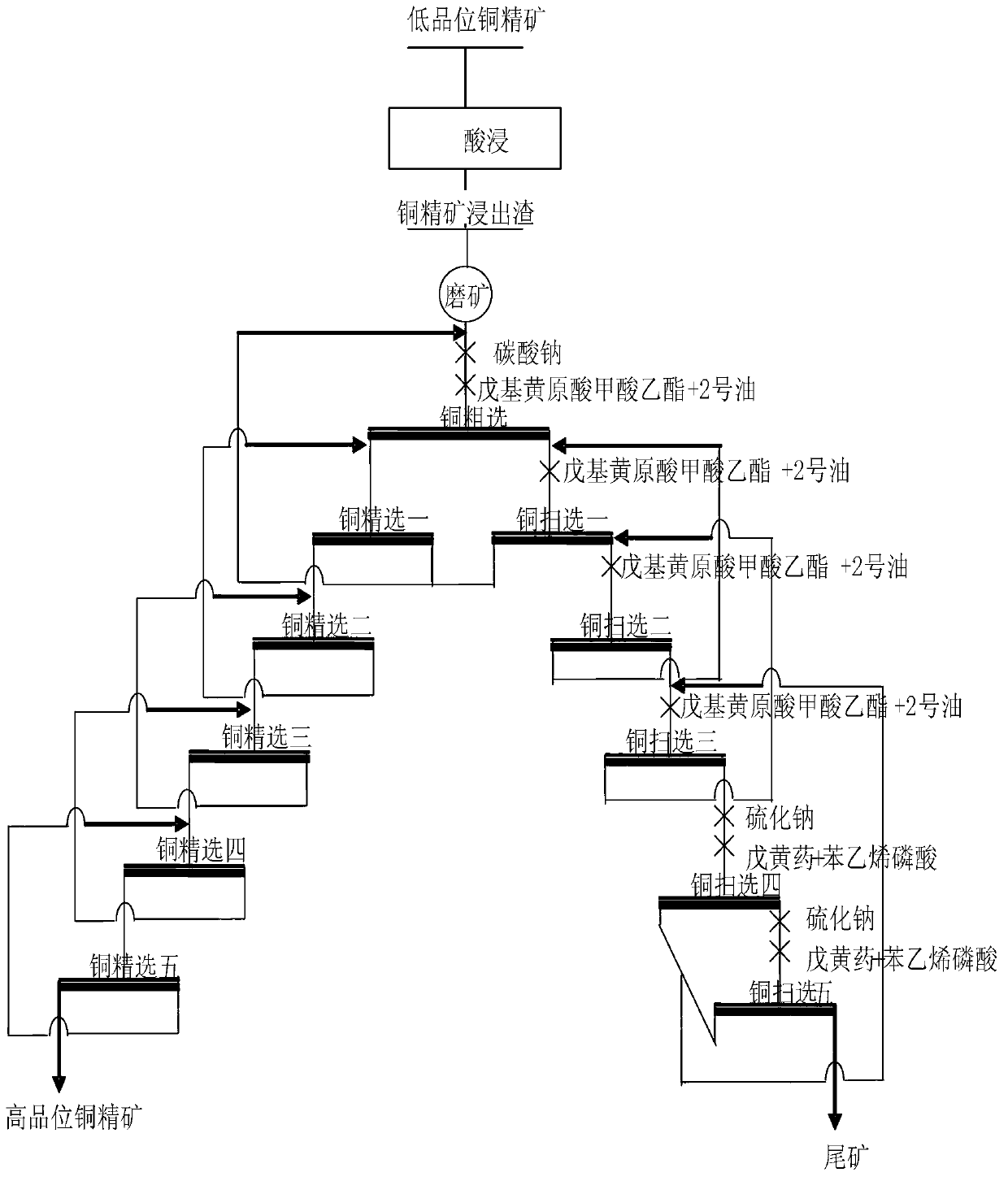

[0025] According to a typical implementation of the present invention, the processing method of the copper concentrate leaching slag is as follows: figure 1 as shown, figure 1 A schematic flow chart of the recovery process of copper concentrate leaching slag is shown. The treatment method includes grinding and preparing pulp and flotation treatment steps, wherein grinding and preparing pulp refers to grinding the mixture of copper concentrate leaching slag and water to prepare pulp, and the particles with a particle size of less than 0.074mm in the pulp account for 90-95% of the total particle weight. %; The flotation process includes rough selection and fine selection in turn.

[0026] The present invention effectively recovers copper sulfide minerals that are relatively difficult to leach and easy to float in copper minerals by adopting processes such as grinding, roughing and beneficiation of the copper concentrate leaching slag, so that the copper sulfide minerals in the ...

Embodiment 1

[0044] Raw material: leaching slag of a mixed copper concentrate in the Democratic Republic of the Congo (containing 13.28% copper)

[0045] Add water to one ton of leaching slag for wet ball milling. When particles with a particle size of less than 0.074mm account for 90% of the total particle weight, adjust the mass percentage concentration of the pulp to 25%, send the pulp into the flotation tank, and add it while stirring. Add 300 grams of sodium carbonate to adjust the pH value of the whole pulp to be 8, add 100 grams of amyl xanthate ethyl formate and 28 grams of terpineol oil to the pulp while stirring, carry out roughing, and the flotation time is 3 minutes. Finally, coarse concentrate and roughing tailings are obtained.

[0046] The roughing tailings are carried out in continuous 5-stage sweeping, wherein 40 grams, 40 grams and 20 grams of amyl xanthate ethyl formate are added successively in copper sweeping one, copper sweeping two and copper sweeping three steps, lo...

Embodiment 2

[0052] Raw material: leaching slag from a mixed copper concentrate in Yunnan (containing 6.85% copper)

[0053] Add water to one ton of leaching slag for wet ball milling. When the particles with a particle size of less than 0.074mm account for 95% of the total particle weight, add water to make the pulp concentration 35%, send the pulp into the flotation tank, and add regulator while stirring 500 grams of sodium carbonate adjust the pH value of the whole pulp to be 10, while stirring, add 150 grams of amyl xanthate ethyl formate and 42 grams of terpineol oil to the pulp at the same time, carry out roughing, the flotation time is 5 minutes, and finally Obtain rough concentrate and roughing tailings.

[0054]Rougher tailings are carried out continuously 5 stages of sweeping, wherein copper sweeping one, copper sweeping two and copper sweeping three steps add 60 grams, 60 grams and 40 grams of amyl xanthate ethyl formate successively, all Add 28 grams of terpineol oil, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com