Preparation method of yttrium aluminum garnet (YAG) nano-powder

A technology of yttrium aluminum garnet and nano-powder, which is applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve the problems of easy powder agglomeration, high equipment requirements, high raw material cost, etc., and achieve high sintering activity, Avoid reunion, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method of yttrium aluminum garnet nano powder, comprising the following steps:

[0031] 1) Dissolve aluminum salt in isopropanol to obtain an aluminum solution with a mass concentration of 15-35 wt%; dissolve yttrium salt and / or acetate of other rare earth ions in deionized water to prepare a mass concentration of 15-35 wt%. The solution A of 25wt%; Wherein,

[0032] The molar ratio of the aluminum salt to the acetate of yttrium salt and / or other rare earth ions is 3:5, the weight and number ratio of the aluminum salt to isopropanol is 1:2 to 1:6, and the yttrium The weight and number ratio of the acetate of salt and / or other rare earth ions to deionized water is 1:3~1:6;

[0033] 2) Under the condition of vigorous stirring, add the aluminum solution dropwise to the solution A, and stir for 1 to 3 hours under the condition of 30-50°C to obtain the sol; then, under the condition of 60-80°C, continue to Stir for 1 to 3 hours to obtain a gel;

[0034] 3) T...

Embodiment 1

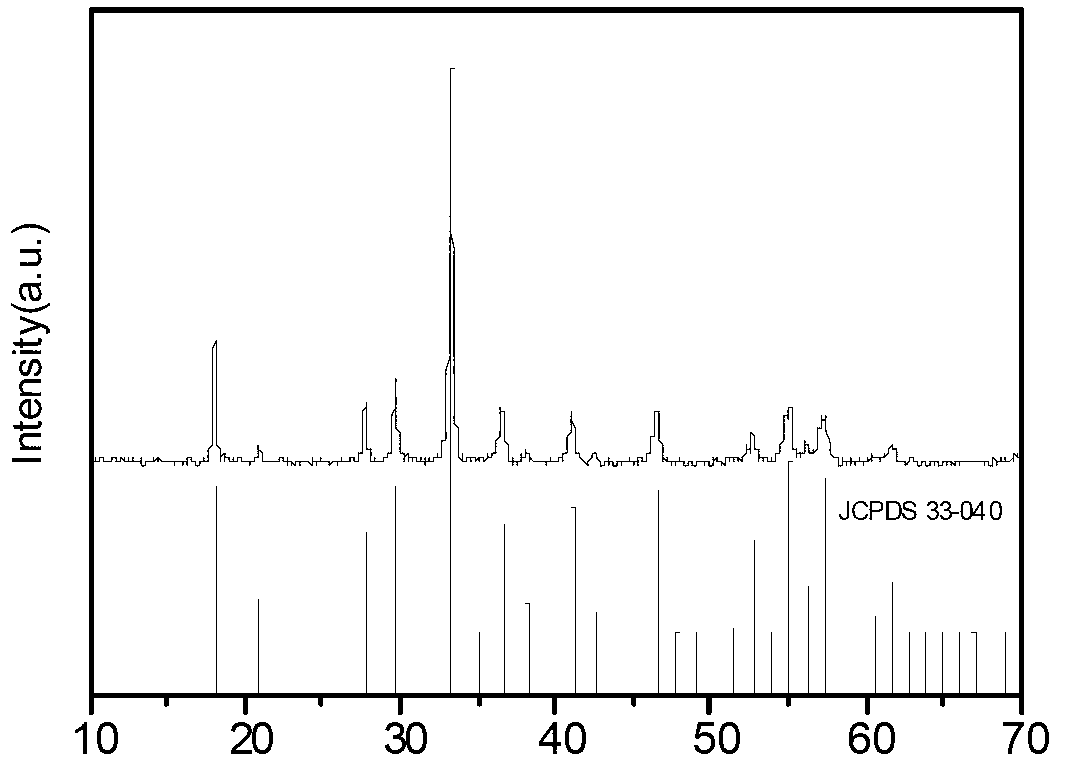

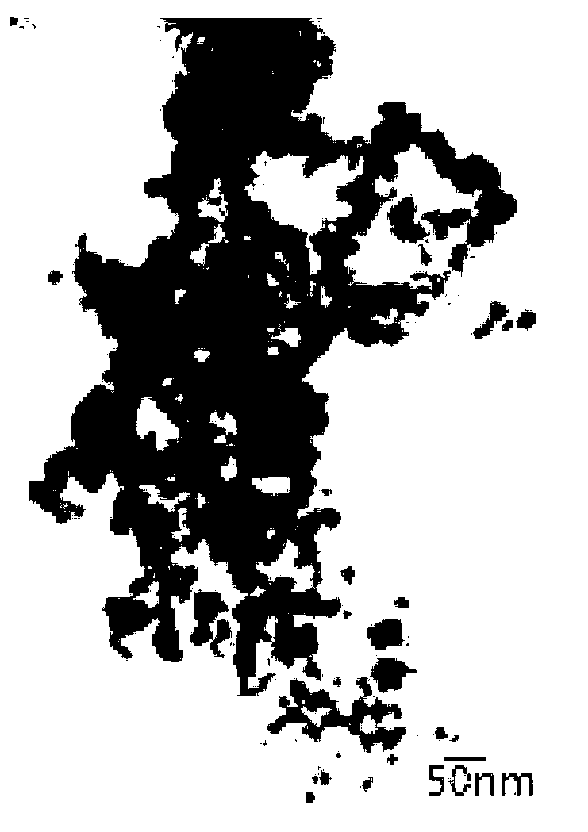

[0039] Take aluminum isopropoxide 102.12 grams and dissolve in 300ml isopropanol to form an aluminum solution, weigh yttrium acetate (molecular formula: Y(CH 3 COO) 3 4H 2 O) 101.43 g was dissolved in 600 ml deionized water to form a solution of yttrium. Under vigorous stirring, the above-mentioned aluminum solution was added dropwise to the yttrium solution, stirred at 40°C for 2 hours to form a sol, raised to 60°C and continued to stir for 3 hours to form a gel. The above gel was transferred to a freeze dryer, pre-frozen at -60°C for 12h, and dried at -60°C and 10Pa for 30h to obtain a loose precursor powder. The precursor powder was calcined at 900 °C for 2 h to obtain the final product. Its XRD spectrum is as figure 1 As shown, compared with the standard card JCPDS33-40, the position and relative intensity of the diffraction peaks are completely consistent, indicating that the product is a pure YAG phase. TEM photos such as figure 2 As shown, the average grain size ...

Embodiment 2

[0041] Take by weighing 102.12 grams of aluminum isopropoxide and dissolve in 600ml of isopropanol to form an aluminum solution, weigh 100.4157 grams of yttrium acetate (molecular formula: the same as Example 1), neodymium acetate (molecular formula: Nd(CH 3 COO) 3 ·H 2 O) 1.0181 g was dissolved in 400 ml of deionized water to form a mixed solution of yttrium and neodymium. Under vigorous stirring, the above-mentioned aluminum solution was added dropwise to the mixed solution of yttrium and neodymium, stirred at 45°C for 2h to form a sol, raised to 70°C and continued to stir for 2h to form a gel. The above gel was transferred to a freeze dryer, pre-frozen at -65°C for 8h, and dried at -65°C and 8Pa for 36h to obtain a loose precursor powder. The precursor powder was calcined at 1000°C for 2 hours, and finally Nd:YAG powder with Nd content of 1.0at% was obtained. Its XRD collection of patterns and TEM picture feature are with embodiment 1. The main technical indicators are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com