Method for enriching phosphorus by using aerobic granular sludge

An aerobic granular sludge and chemical technology, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc. The effect of denitrification and carbon removal is good, the cost of capital construction is reduced, and the operation is stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

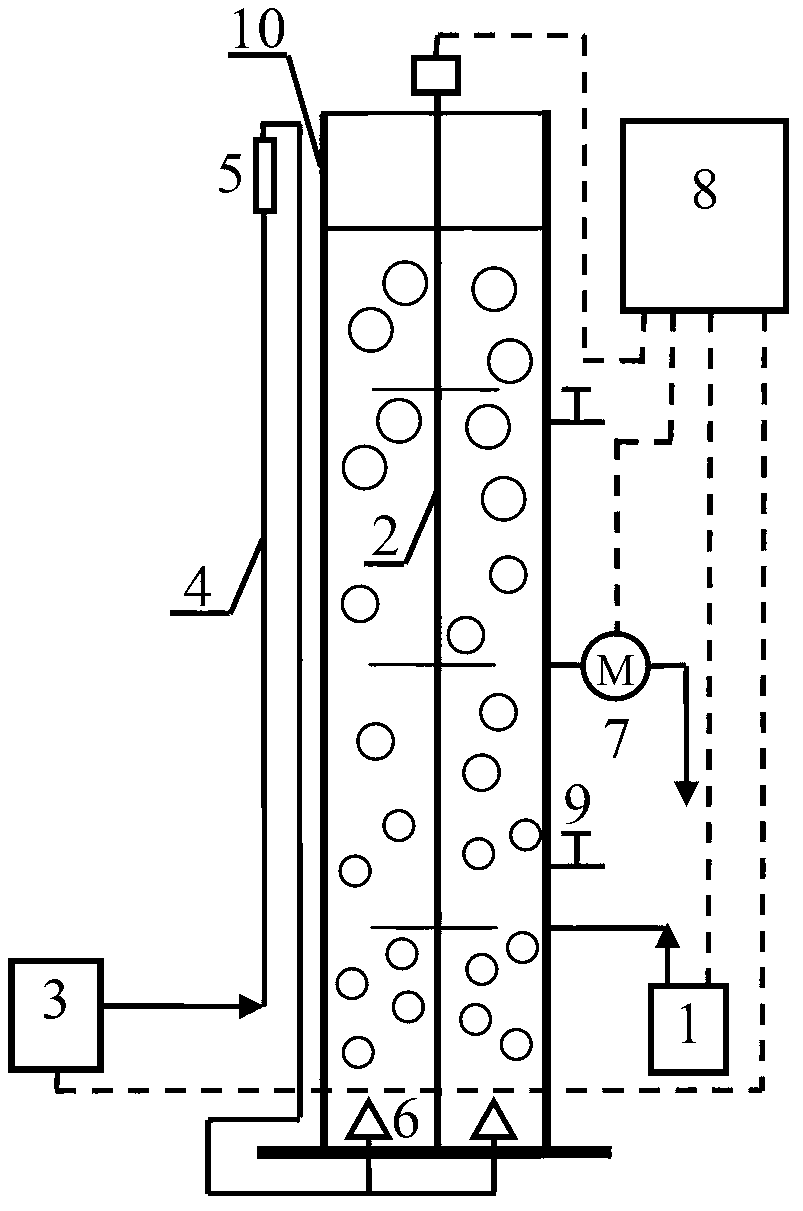

[0050] In this embodiment, a kind of aerobic granular sludge process enriched with chemical phosphorus adopts a sequence batch reactor (SBR) with an aspect ratio of 9, such as figure 1 Shown: The main body of the reactor is composed of plexiglass, the total volume of the reactor is 9L, and the working volume is 7L; the bottom of the reactor is equipped with a microporous aeration head 6, which is connected with an external air compressor 3 by an air pipe 4 for aeration. The flow rate is adjusted by the rotameter 5, the stirring is realized by the stirring paddle 2, the reactor is drained by the solenoid valve 7, and the water is fed by the water inlet pump 1, and the whole process is automatically operated under the control of the time controller 8.

[0051] In this case, the operation process of using the above-mentioned SBR to cultivate an aerobic granular sludge enriched in chemical phosphorus is as follows:

[0052] (1) Inoculate the flocculent sludge at the end of the aer...

Embodiment 2

[0063] Reactor used in the present embodiment is with embodiment 1, and concrete operating process is as follows:

[0064] (1) Inoculate the flocculent sludge at the end of the aeration tank of a sewage treatment plant, inoculate 2.5L into the reactor after sedimentation and concentration, add artificially prepared influent water to the working volume of the reactor at 7L (total of the sequencing batch reactor The volume is 9L), the sludge concentration at this time is maintained at 1000mg / L, the sludge is acclimated by continuous aeration for 24 hours, and then the sludge is settled for 2 hours, and the supernatant is discharged to the outlet of the reactor;

[0065] (2) Ingress of water,

[0066] The influent water quality is artificially distributed, and the quality of the distributed water is: COD is 600mg / L, NH 4 Cl is 115mg / L, KH 2 PO 4 43.9-87.8mg / L, Ca 2+ 60mg / L, Mg 2+ 20-30mg / L, trace elements: FeCl 3 ·6H 2 O is 1.5mg / L, H 3 BO 3 0.15mg / L, CuSO 4 ·5H 2 O is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com