Electrostatic capacitor based on nano-electrode and preparation method thereof

An electrostatic capacitor and nano-electrode technology, which is applied to fixed capacitor electrodes, multiple fixed capacitors, and fixed capacitor dielectrics, etc., can solve the problems of inability to guarantee product performance consistency, difficulty in reducing product preparation costs, and unfavorable product commercial application. Achieve the effect of reducing investment and production costs, high breakdown voltage, and high working voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The concrete steps of preparation are:

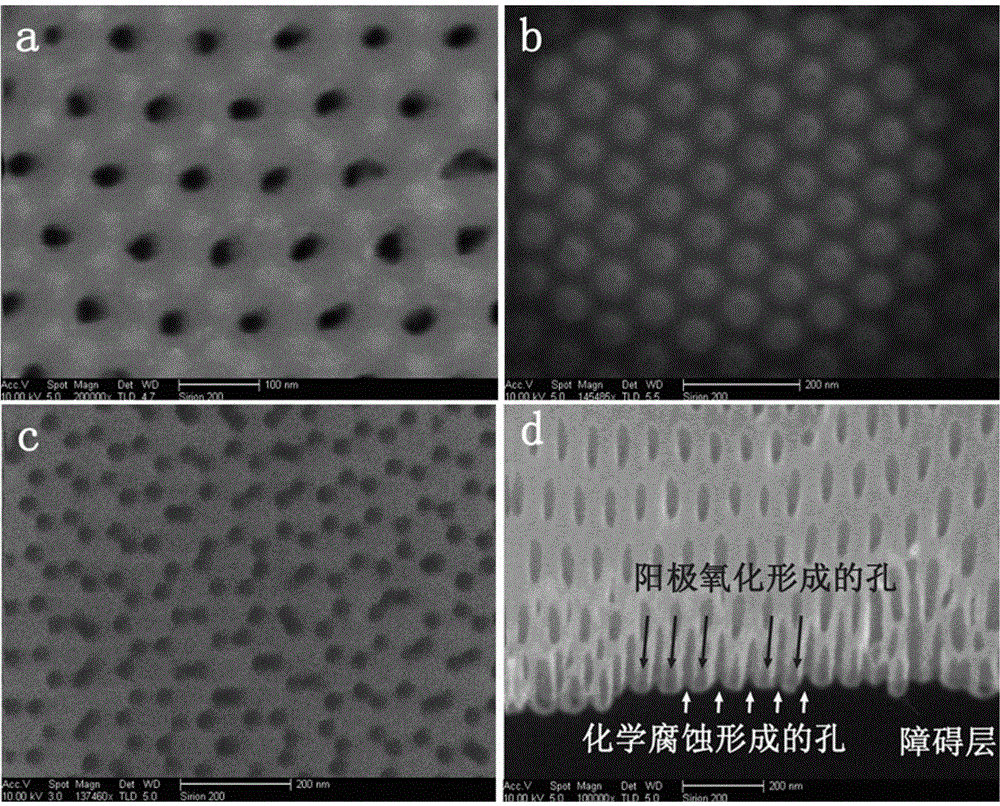

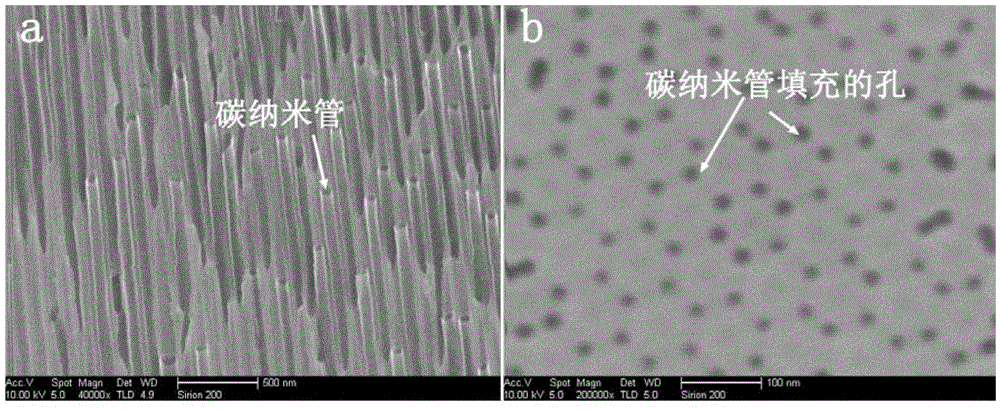

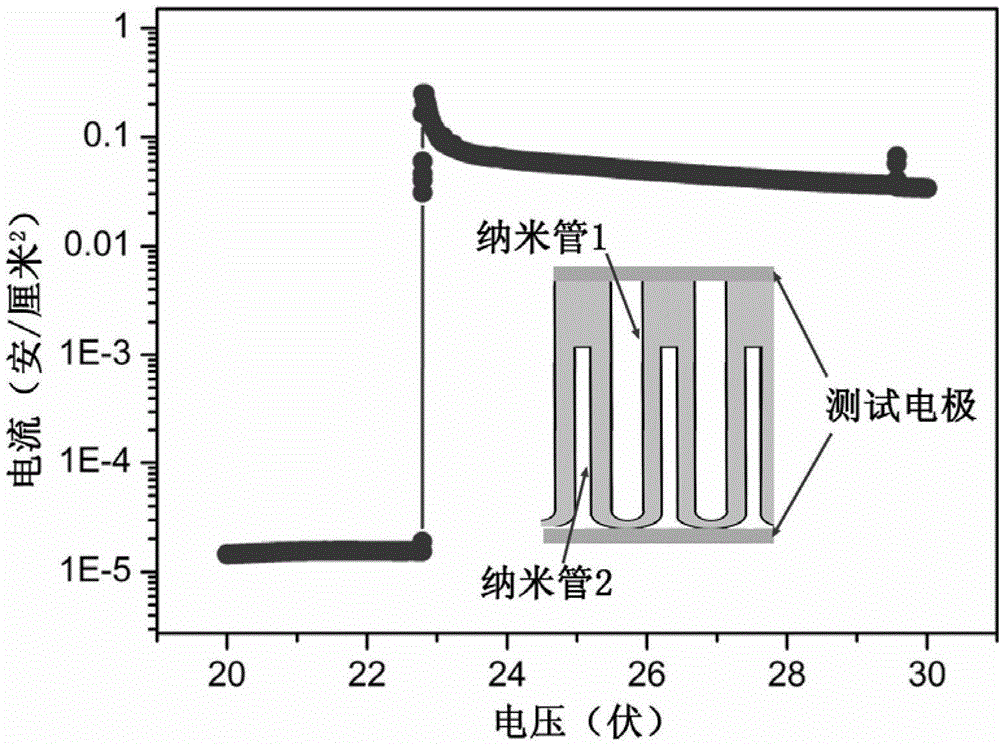

[0024]Step 1, the aluminum sheet is ultrasonically cleaned with acetone, ethanol and deionized water, and then blown dry with nitrogen; then it is placed in a sulfuric acid solution with a temperature of 0°C and a concentration of 0.2mol / L, under a DC voltage of 25V Anodized for 2h, the approximate figure 1 Primary alumina template shown in a. Then put the primary alumina template in a mixed solution of sulfuric acid solution with a concentration of 0.7mol / L and an aluminum sulfate solution with a concentration of 0.15mol / L at a temperature of 20°C. 2 Rise to 160mA / cm 2 After 4min of anodic oxidation under the DC constant current; it is placed in a saturated solution of tin tetrachloride to remove the unoxidized aluminum on the back, and an approximate figure 1 As shown in b, the first hole array is arranged on one side, and the arc-shaped barrier layer formed by the holes of the first hole array on the back is provided with a...

Embodiment 2

[0027] The concrete steps of preparation are:

[0028] Step 1, the aluminum sheet is ultrasonically cleaned with acetone, ethanol and deionized water, and then blown dry with nitrogen; then it is placed in a sulfuric acid solution with a temperature of 0.7°C and a concentration of 0.25mol / L, under a DC voltage of 29V Anodized for 1.8h, obtained approximately figure 1 Primary alumina template shown in a. Then put the primary alumina template in a mixed solution with a concentration of 0.75 mol / L of sulfuric acid solution and a concentration of 0.13 mol / L of aluminum sulfate solution at a temperature of 23°C. 2 Rise to 160mA / cm 2 After 3.5min of anodic oxidation under the DC constant current; it is placed in a saturated solution of tin tetrachloride to remove the unoxidized aluminum on the back, and an approximate figure 1 As shown in b, the first hole array is arranged on one side, and the arc-shaped barrier layer formed by the holes of the first hole array on the back is pr...

Embodiment 3

[0031] The concrete steps of preparation are:

[0032] Step 1, the aluminum sheet is ultrasonically cleaned with acetone, ethanol and deionized water, and then blown dry with nitrogen; then it is placed in a sulfuric acid solution with a temperature of 1.5°C and a concentration of 0.3mol / L, under a DC voltage of 33V Anodized for 1.5h, obtained as figure 1 Primary alumina template shown in a. Then put the primary alumina template in a mixed solution with a concentration of 0.8 mol / L of sulfuric acid solution and a concentration of 0.1 mol / L of aluminum sulfate solution at a temperature of 25°C. 2 Rise to 160mA / cm 2 After anodizing for 3min under a DC constant current; place it in a saturated solution of tin tetrachloride to remove the unoxidized aluminum on the back, and obtain the following figure 1 As shown in b, the first hole array is arranged on one side, and the arc-shaped barrier layer formed by the holes of the first hole array on the back is provided with a secondar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com