Preparation method of metal surface plasmon polariton-CdSe composite porous anodes

A technology of plasmonic polariton and porous anode, which is applied in the field of solar cells, can solve the problems of complicated purification process, cumbersome preparation process, high cost and unfavorable cost, and achieve the effect of increasing the transmission distance, simple preparation process, and improving battery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

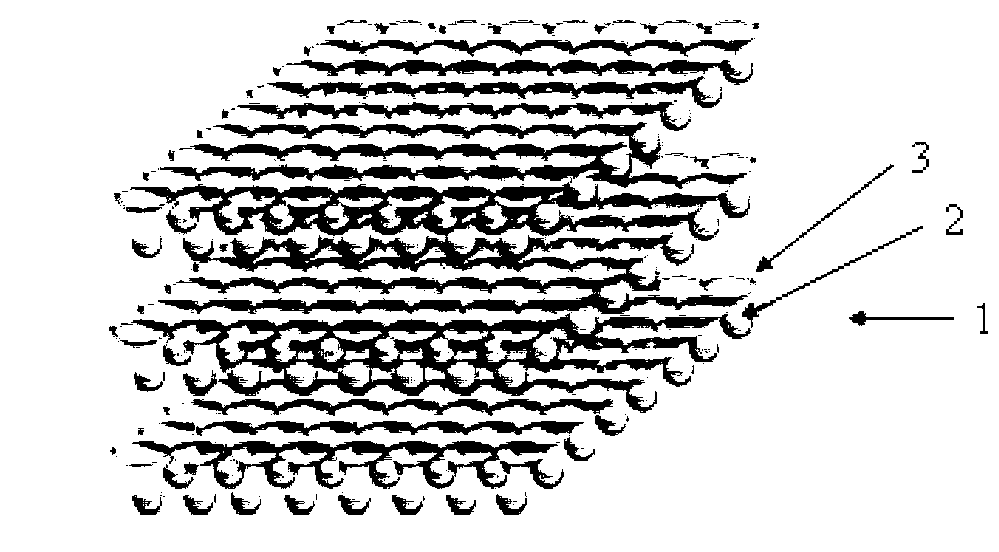

[0047] In this example, a single-layer ITO-Au(300s)-CdSe composite porous anode was prepared by an electrochemical method. Its preparation process is as follows:

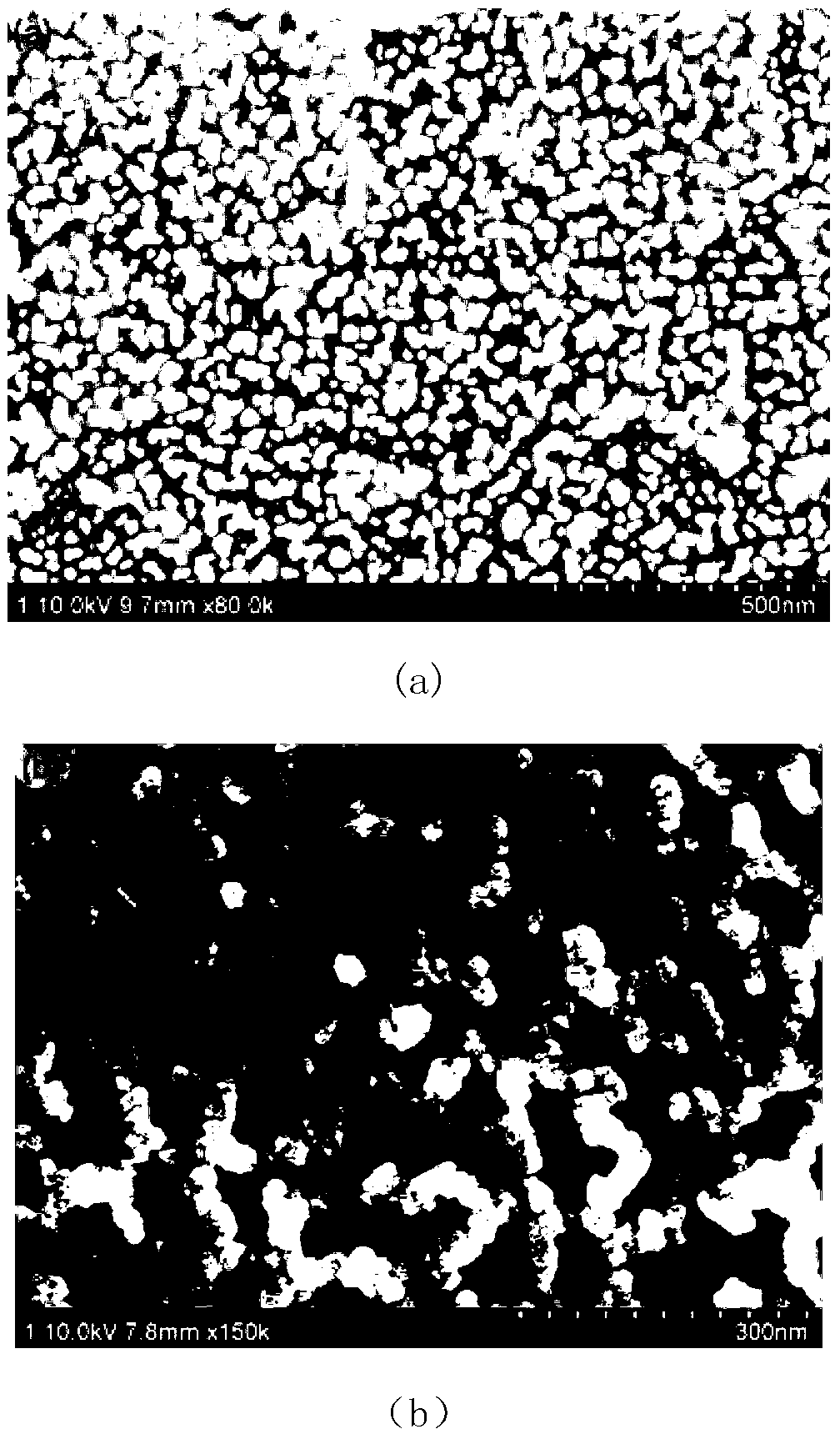

[0048] Step 1, on the surface of clean and dry ITO conductive glass 1, utilize electrochemical method to deposit gold nanoparticles 2 (see figure 1 ). The electrodeposition solution used in the electrochemical method is composed of chloroauric acid aqueous solution and sodium sulfate solution, wherein the concentration of chloroauric acid is 10 mmol / L. Moreover, a three-electrode system is adopted: ITO conductive glass 1 is used as the working electrode, the Pt sheet is used as the counter electrode, and the saturated calomel electrode (SCE) is used as the reference electrode; the model of the electrochemical workstation is CHI630D, and the constant potential mode is adopted, and the deposition voltage is - 0.8 V, the deposition time is 300s. The surface morphology of the obtained samples was determined by s...

Embodiment 2

[0052] In step 1 of this embodiment, gold nanoparticles 2 are deposited on the surface of ITO conductive glass 1 by electrochemical method (see figure 1 ). The electrodeposition solution used in the electrochemical method is composed of chloroauric acid aqueous solution and sodium sulfate solution, wherein the concentration of chloroauric acid is 15 mmol / L; the deposition voltage is -1.2V, and the deposition time is 100s. The surface morphology of the sample of the ITO conductive glass with gold nanoparticles deposited on the surface prepared in this embodiment is measured by scanning electron microscope, as image 3 (a) shown. Depend on image 3 (a) It can be seen that gold nanoparticles are evenly distributed on the surface of ITO conductive glass, and the diameter of gold nanoparticles is distributed in the range of 10-20nm. It can be seen that the deposition time is reduced and the particle size of gold nanoparticles becomes smaller. The ultraviolet-visible absorption ...

Embodiment 3

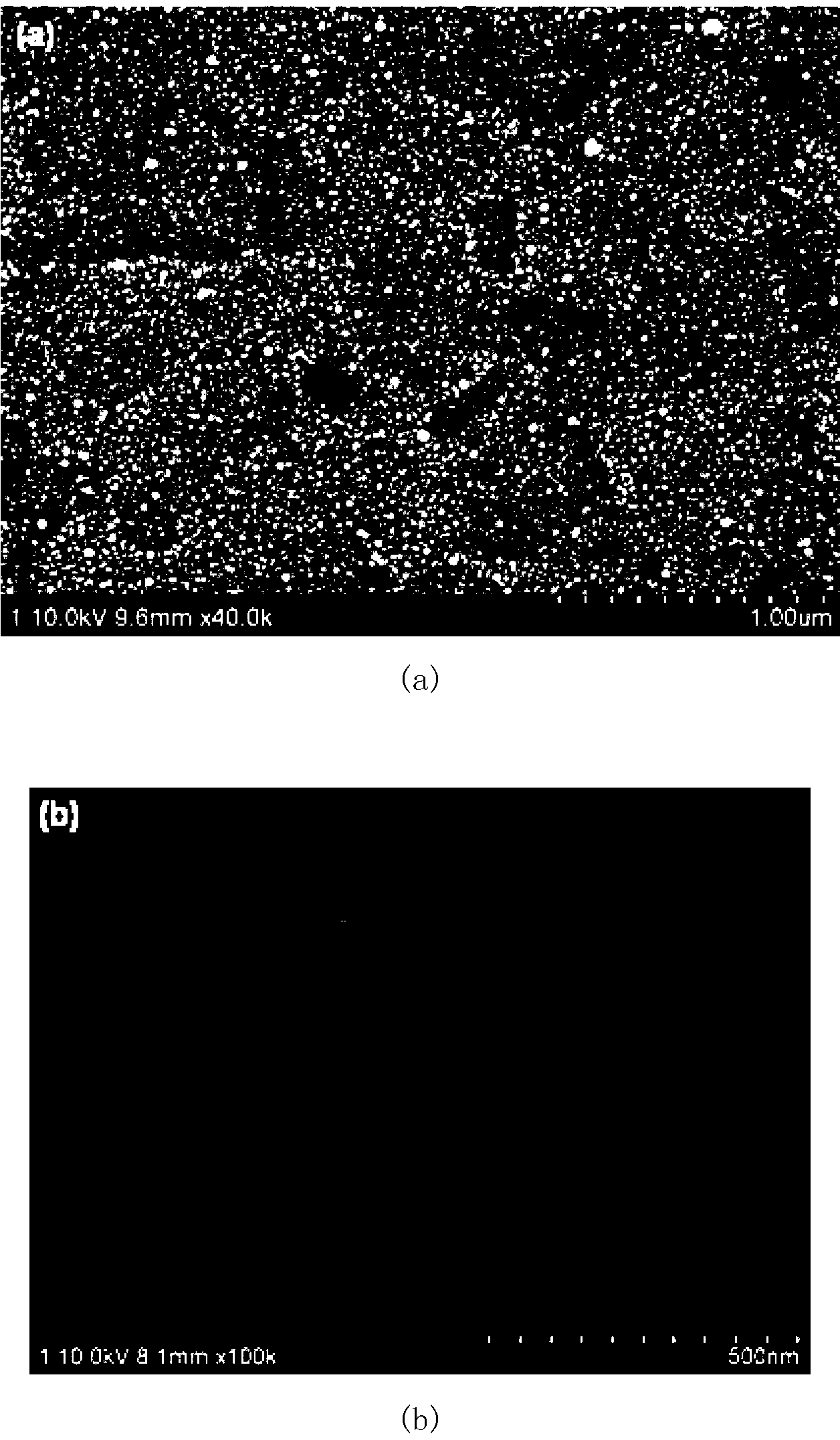

[0056] In step 1 of this embodiment, gold nanoparticles 2 are deposited on the surface of ITO conductive glass 1 by electrochemical method (see figure 1 ). The electrodeposition solution used in the electrochemical method is composed of chloroauric acid aqueous solution and sodium sulfate solution, wherein the concentration of chloroauric acid is 12 mmol / L. The deposition voltage was -1.0V, and the deposition time was 600s. The surface morphology of the sample of the ITO conductive glass with gold nanoparticles deposited on the surface prepared in this embodiment is measured by scanning electron microscope, as Figure 4 (a) shown. from Figure 4 (a) It can be seen that the gold nanoparticles are evenly distributed on the surface of the ITO conductive glass, and the diameter of the gold nanoparticles is distributed in the range of 30-50nm. It can be seen that the density of gold nanoparticles increases as the deposition time increases. The ultraviolet-visible absorption cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com