Environmentally-friendly jean crack slurry and crack jean fabric making method

A denim fabric and cracking technology, which is applied in the processing of denim fabric and textile processing, can solve the problems of secondary pollution of water resources, affecting processing, wax is not easy to clean, etc., and achieve the effect of reducing pollution and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

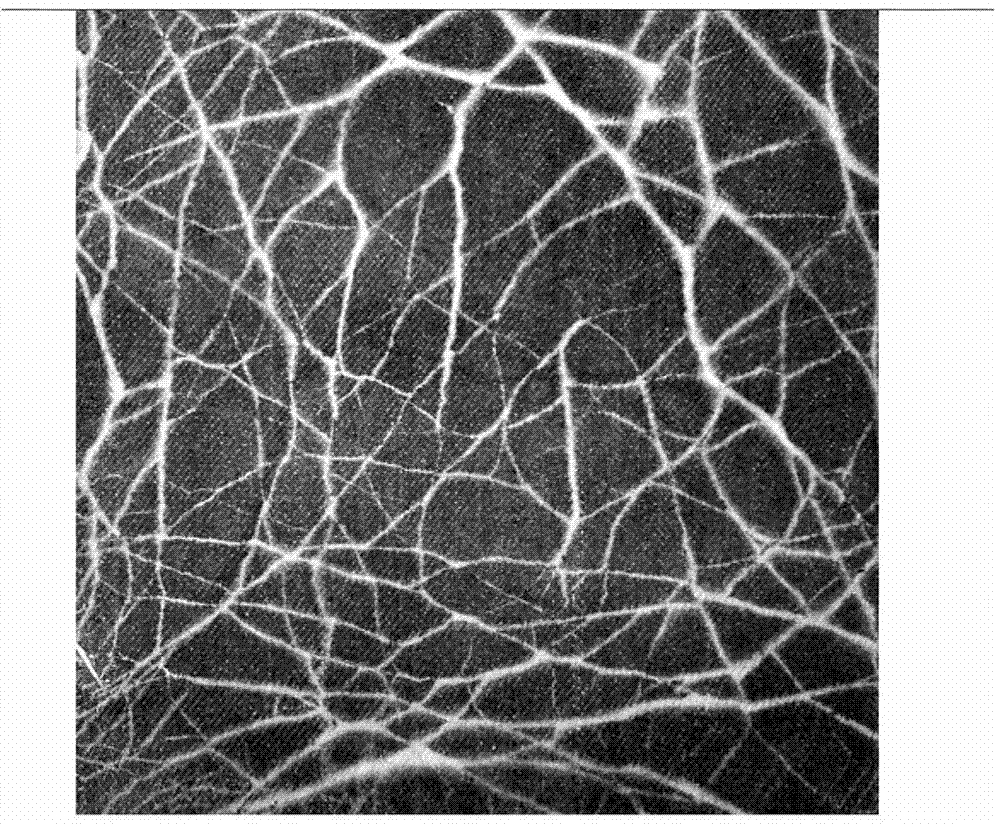

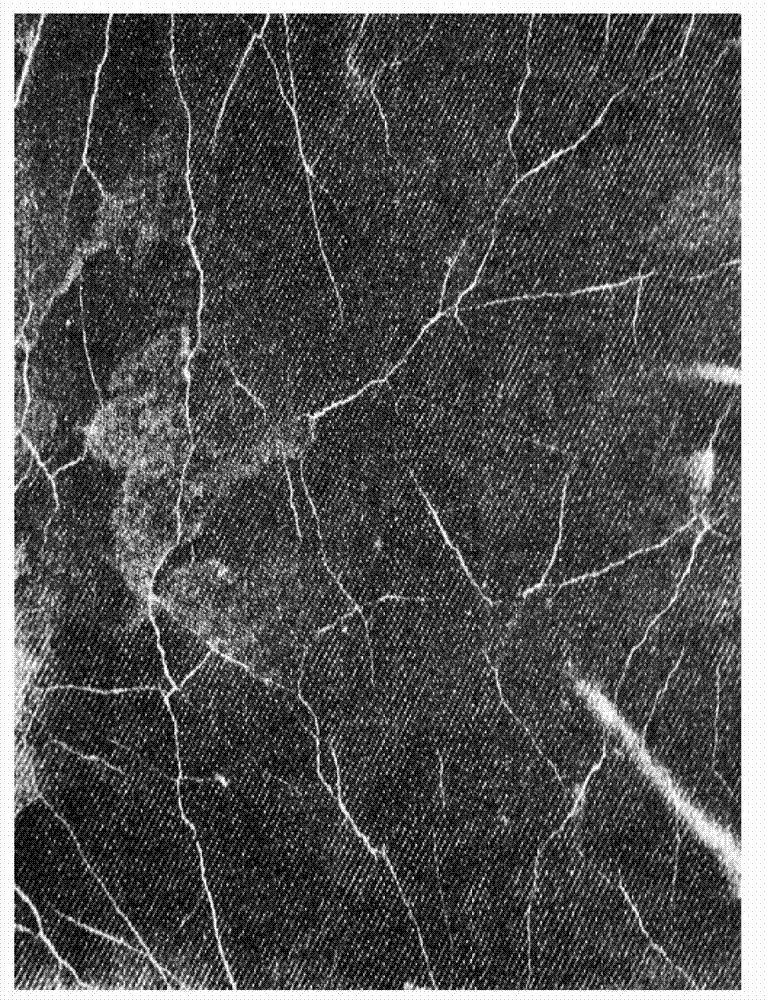

Image

Examples

Embodiment 1

[0050] Composition of slurry:

[0051] Composite Portland cement 20 parts

[0052] Ca(OH) 2 10 servings

[0053] CaCO 3 1 serving

[0054] JS waterproofing agent 3 parts (ie water-soluble polymer acrylic copolymer)

[0055] 2 parts water

[0056] Manufacturing method of cracked denim fabric: a. Scrape the adjusted slurry on the fabric evenly with a scraper, and control the thickness of the slurry to 1~2mm; b. Move the fabric into the oven (or drying room) and heat up to 140°C at a rate of 5°C / min. Drying; c. After the slurry is completely dry, the temperature drops to 0~35℃; d. Spray oxidizing reagent (KMnO 4 With H 3 PO 4 The mixed solution with a mass ratio of 50:1) is used for cracking treatment. During the treatment, the oxidant attached to the slurry naturally flows back into the processing container placed under the fabric under the action of gravity; e. Rinse the fabric, The slurry and the remaining oxidant are cleaned by mechanical kneading, and after proces...

Embodiment 2

[0059] Composition of slurry:

[0060] Composite Portland cement 20 parts

[0061] Ca(OH) 2 8 servings

[0062] CaCO 3 1 serving

[0063] HY inorganic aluminum salt waterproofing agent powder 2 parts

[0064] 2 parts water

[0065] Manufacturing method of cracked denim fabric: a. Scrape the adjusted slurry evenly on the fabric with a scraper, and control the thickness of the slurry to 4~5mm; b. Move the fabric into the oven (or drying room) and heat up to 140°C at a rate of 8°C / min. Drying; c. After the slurry is completely dry, the temperature drops to 0~35℃; d. Spray oxidizing reagent (KMnO 4 With H 3 PO 4 The mixed solution with a mass ratio of 45:1) is used for cracking treatment. During the treatment, the oxidant attached to the slurry naturally flows back into the processing container placed under the fabric under the action of gravity; e. Rinse the fabric, The slurry and the remaining oxidant are cleaned by mechanical kneading, and a...

Embodiment 3

[0067] Composition of slurry:

[0068] 15 parts of white cement

[0070] 2 parts of silicone waterproofing agent RQ301

[0071] 1.5 parts of white latex

[0072] Manufacturing method of cracked denim fabric: a. Scrape the adjusted slurry on the fabric evenly with a scraper, and control the thickness of the slurry to 4~5mm; b. Move the fabric into the oven (or drying room) and heat up to 140°C at a rate of 6°C / min. Drying; c. After the slurry is completely dry, the temperature drops to 0~35℃; d. Spray oxidizing reagent (KMnO 4 With H 3 PO 4 The mixed solution with a mass ratio of 50:1) is used for cracking treatment. During the treatment, the oxidant attached to the slurry naturally flows back into the processing container placed under the fabric under the action of gravity; e. Rinse the fabric, The slurry and the remaining oxidant are cleaned by mechanical kneading, and after processing in the subsequent process, a denim fabric with a cracked appearance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com