a concrete pole

A technology for concrete and electric poles, which is applied to buildings, towers, building types, etc., can solve problems such as low brittleness, achieve good chemical corrosion resistance, improve mechanical performance, and reduce weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

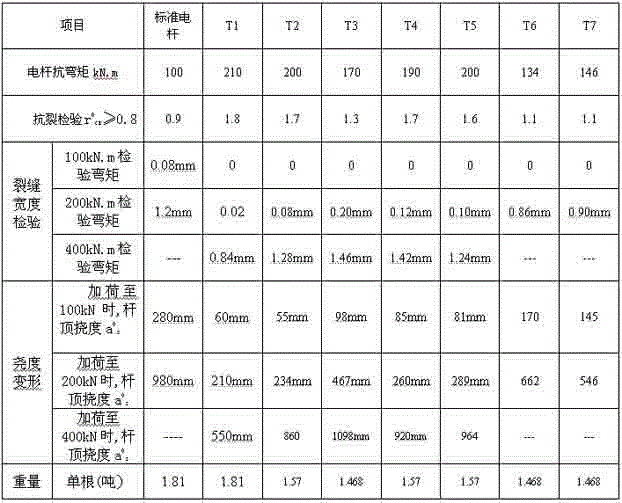

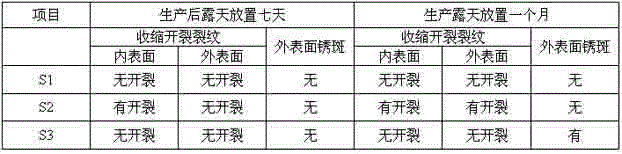

Examples

Embodiment 1

[0051] Prepare concrete raw materials according to the following proportions:

[0052] 510 parts of low-alkali Portland cement or ordinary Portland cement with an average particle size of 30-60 μm;

[0053] Average particle size 0.18μm, SiO 2 130 parts of silica fume with content ≥85%;

[0054] 95 parts of Class I fly ash with an average particle size of 10-20 μm (calcium oxide calcium content ≤ 10%);

[0055] 125 parts of S95 grade or above slag powder with an average particle size of 10-30 μm;

[0056] 525 parts of quartz sand with a particle size of 0.16~1.63mm;

[0057] 890 pieces of stones with a particle size of 5-14mm (crushing index less than 10, needle flake content less than 5%, mud content less than 0.5%);

[0058] 16 parts of composite high-efficiency water reducer with a water reducing rate greater than 30%;

[0059] 9 parts of rust inhibitor;

[0060] 130 parts of water;

[0061] 90 parts of copper-coated steel fibers with a diameter of 0.18~0.25mm and a len...

Embodiment 2

[0090] Prepare concrete raw materials according to the following proportions:

[0091] 480 parts of low-alkali Portland cement or ordinary Portland cement with an average particle size of 30-60 μm;

[0092] Average particle size 0.18μm, SiO 2 120 parts of silica fume with content ≥85%;

[0093] 80 parts of Class I fly ash with an average particle size of 10-20 μm (calcium oxide content ≤ 10%);

[0094] 110 parts of S95 grade or above slag powder with an average particle size of 10-30 μm;

[0095] 510 parts of quartz sand with a particle size of 0.16~1.63mm;

[0096] 920 pieces of stones with a particle size of 5-14mm (crushing index less than 10, needle flake content less than 5%, mud content less than 0.5%);

[0097] 14 parts of composite high-efficiency water reducer with water reducing rate greater than 30%;

[0098] 7 parts of rust inhibitor;

[0099] 120 parts of water;

[0100] 70 parts of copper-coated steel fibers with a diameter of 0.18~0.25mm and a length of 1...

Embodiment 3

[0125] Prepare concrete raw materials according to the following proportions:

[0126] 550 parts of low-alkali Portland cement or ordinary Portland cement with an average particle size of 30-60 μm;

[0127] Average particle size 0.18μm, SiO 2 140 parts of silica fume with content ≥85%;

[0128] 110 parts of Class I fly ash with an average particle size of 10-20 μm (calcium oxide calcium content ≤ 10%);

[0129] 140 parts of S95 grade or above slag powder with an average particle size of 10-30 μm;

[0130]550 parts of quartz sand with a particle size of 0.16~1.63mm;

[0131] 860 parts of stones with a particle size of 5-14mm (crushing index less than 10, needle flake content less than 5%, mud content less than 0.5%);

[0132] 18 parts of composite high-efficiency water reducer with a water reducing rate greater than 30%;

[0133] 12 parts of rust inhibitor;

[0134] 140 parts of water;

[0135] 110 parts of copper-coated steel fibers with a diameter of 0.18~0.25mm and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com