Preparation method of attapulgite supported ferroferric oxide

A technology of triiron tetroxide and attapulgite, which is applied in the directions of oxidizing water/sewage treatment, etc., can solve the problems of secondary water pollution, etc., and achieve the effects of increasing adsorption capacity, simple preparation method and improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

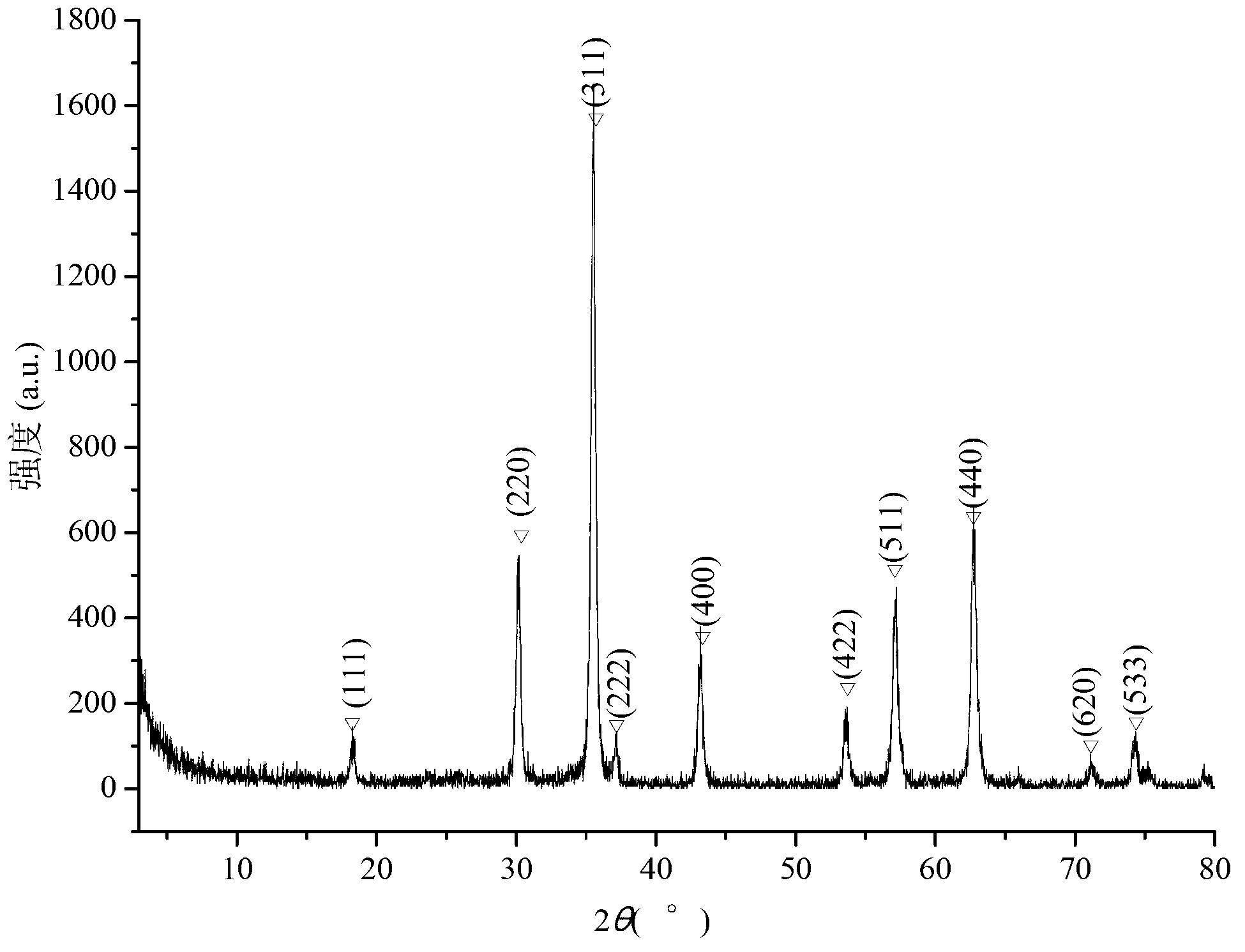

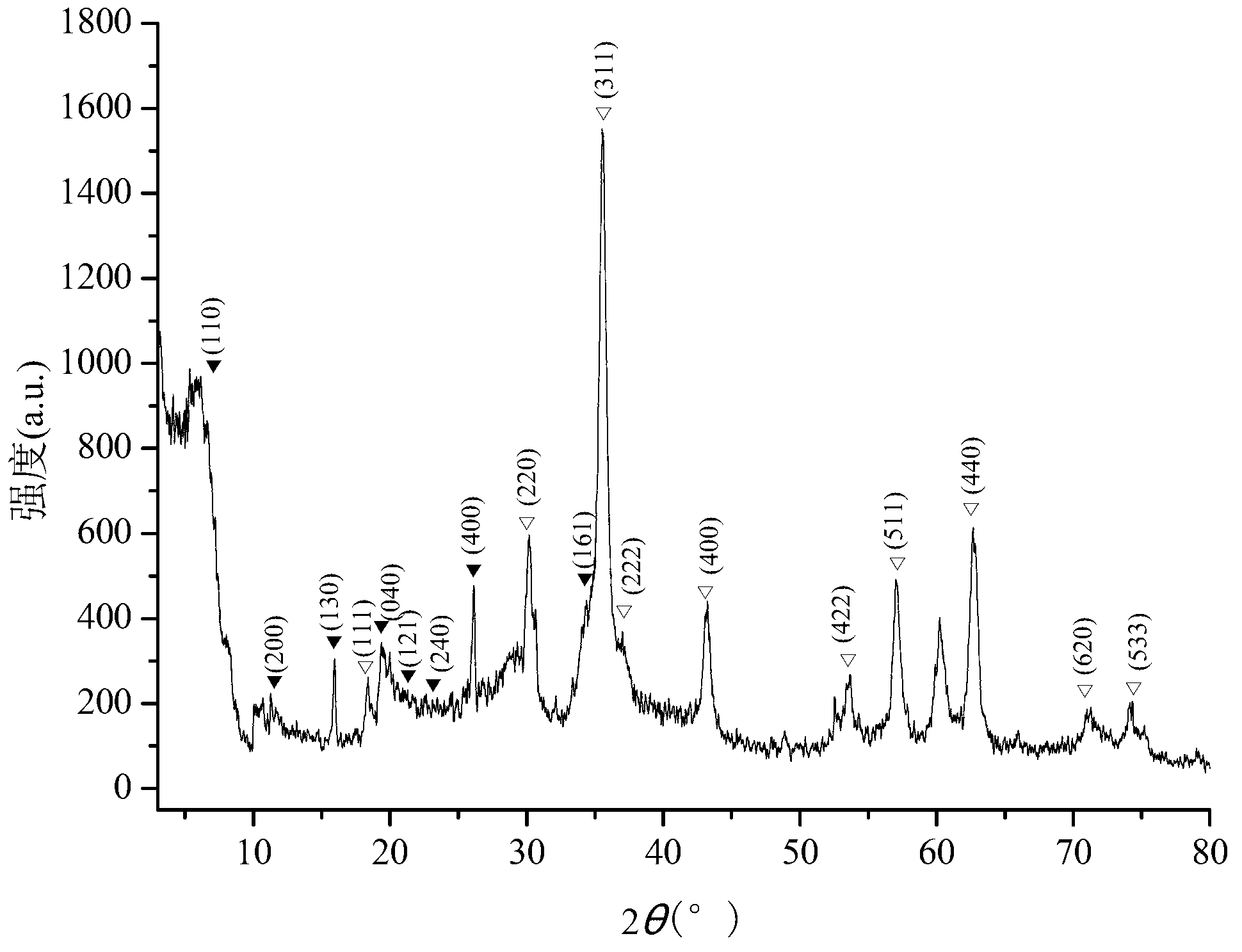

[0031] Example 1: Attapulgite loaded Fe with a loading ratio of 2:1.13 3 o 4 preparation of

[0032] 1. Pass attapulgite clay (Guanshan attapulgite clay mine, Mingguang City, Anhui Province) through a 200-mesh sieve after crushing and grinding to obtain off-white powder for use;

[0033] 2. Introduce N into a 100 mL three-necked flask 2 After removing the air in the bottle, add 2g of prepared attapulgite powder, add 4.06g of FeSO 4 ·7H 2 O, add 30 mL of distilled water, heat and stir in a water bath at 60 °C for 20 min, so that the attapulgite can fully absorb Fe2+ ;

[0034] 3. Add 3 mL of hydrogen peroxide with a mass fraction of 10% dropwise, and continue to react for 10 min after the dropwise addition is completed;

[0035] 4. Add 1 mol / L NaOH solution dropwise into the three-necked flask until the pH of the reaction system is 12, and continue to react for 10 min;

[0036] 5. Transfer all the system in the three-necked flask to a polytetrafluoroethylene reactor, and ...

Embodiment 2

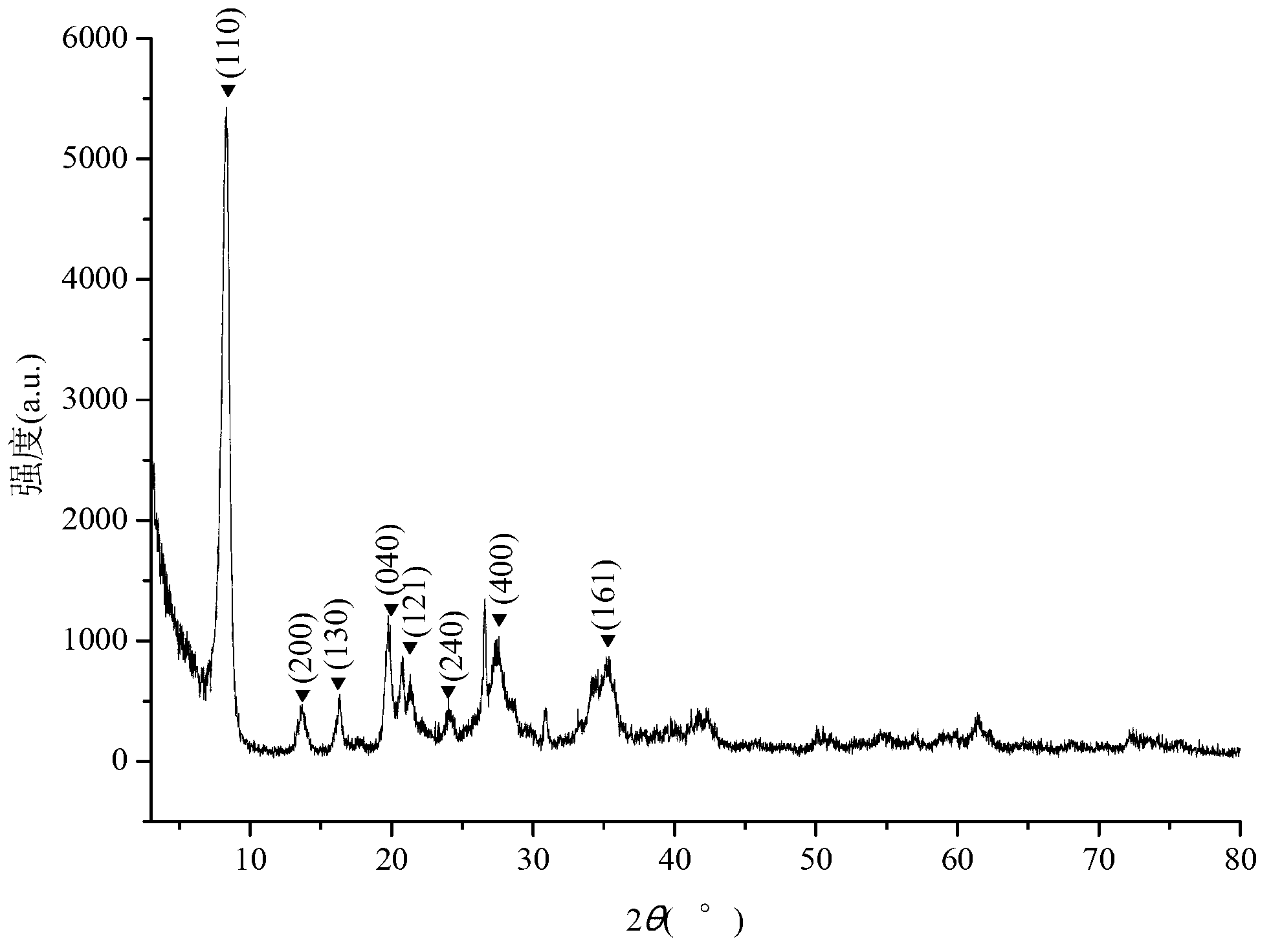

[0037] Example 2: Attapulgite loaded Fe with a loading ratio of 1:2 3 o 4 preparation of

[0038] 1. Pass attapulgite clay (Guanshan attapulgite clay mine, Mingguang City, Anhui Province) through a 200-mesh sieve after crushing and grinding to obtain off-white powder for use;

[0039] 2. Introduce N into a 100 mL three-necked flask 2 After removing the air in the bottle, add 1 g of prepared attapulgite powder, add 7.2 g of FeSO 4 ·7H 2 O, add 40 mL of distilled water, heat and stir in a water bath at 60 °C for 20 min, so that attapulgite can fully absorb Fe 2+ ;

[0040] 3. Add 1 mL of hydrogen peroxide with a mass fraction of 16.8% dropwise, and continue to react for 10 minutes after the dropwise addition is completed;

[0041] 4. Add 2 mol / L NaOH solution dropwise into the three-necked flask until the pH of the reaction system is 13, and continue to react for 10 min;

[0042] 5. Transfer all the system in the three-necked flask to a polytetrafluoroethylene reactor, an...

Embodiment 3

[0043] Example 3: Attapulgite loaded Fe 3 o 4 Catalytic Oxidative Degradation Performance of Methylene Blue.

[0044] In a 250 mL three-neck flask, add 100 mL of methylene blue solution with a concentration of 250 μmol / L, adjust its pH to 4, and add 0.1 g of attapulgite-loaded Fe 3 o 4 Catalyst (loading ratio 3:1), heated and stirred in a water bath at 60 °C. Add 1 mL of hydrogen peroxide with a mass fraction of 17% dropwise, react for 40 min, and detect the residual methylene blue concentration (the spectrophotometer uses a 10 mm cuvette to detect at 664 nm, and a working curve needs to be drawn for the detection). Two sets of comparative experiments were set up: one group only added catalyst without adding hydrogen peroxide, and one group only added hydrogen peroxide without catalyst. After a period of reaction, the residual amount of methylene blue in water (μmol / L) was as follows:

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com