Collagenase producing strain

A collagen and collagen tripeptide technology, applied in the direction of bacteria, microorganisms, and methods based on microorganisms, can solve the problems of uneven molecular weight and low collagen tripeptide content, and meet simple nutritional requirements, high collagenase activity, and tolerance The effect of strong temperature capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

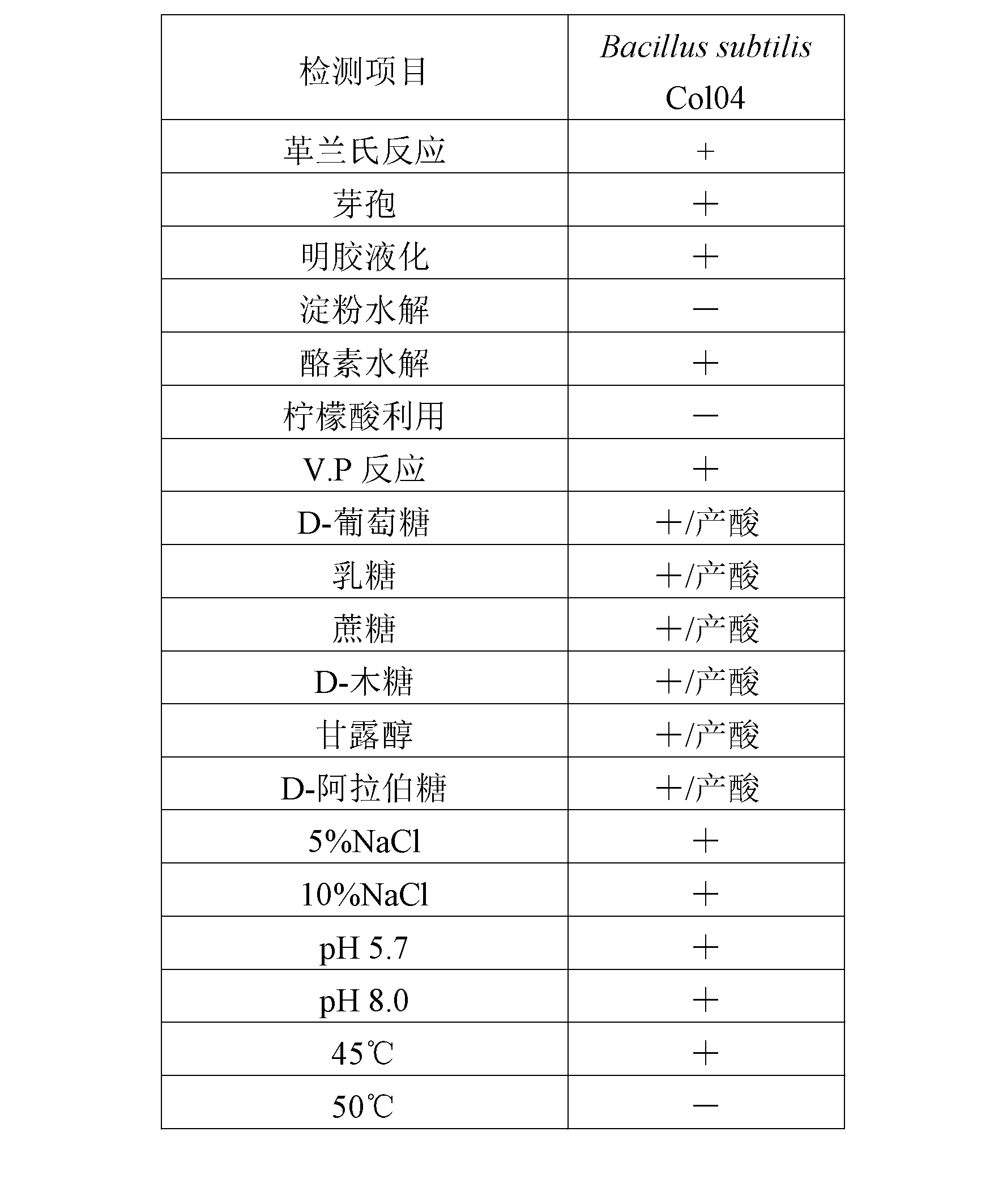

Image

Examples

preparation example Construction

[0028] 1. Preparation of collagenase

[0029] Select LB medium (the components of LB medium are as follows: tryptone 10g / L, yeast extract 5g / L, sodium chloride 10g / L), adjust the pH to 7.5, and expand the culture of bacteria at 37°C and 200rpm for 24 After 1 hour, the cultivation was stopped, and a seed solution was obtained.

[0030] Take 5ml seed liquid and inoculate it into 100mL enzyme production medium (the composition of enzyme production medium is as follows: glucose 20g / L, yeast extract 1.5 g / L, tryptone 10g / L, calcium chloride 0.05 g / L, magnesium chloride 0.165 g / L, dipotassium hydrogen phosphate 0.25 g / L, sodium dihydrogen phosphate 0.5 g / L, pH 7.5.), cultivated at 30°C, 200rpm for 36 hours, after the cultivation, centrifuged at 4°C, 10000rpm for 10min, collected Fermentation supernatant.

[0031] The supernatant was first precipitated with ammonium sulfate, and the precipitate was collected by centrifugation; the precipitate was redissolved in Tris-Hcl buffer sol...

Embodiment 1

[0039] Embodiment 1: Utilize Bacillus subtilis Col04 fermented liquid to the degradation of fish skin collagen

[0040]1) Preparation of seed solution:

[0041] The LB medium was selected, the pH was adjusted to 7.5, and the bacteria were expanded and cultured at 37° C. and 200 rpm for 24 hours, and the culture was stopped to obtain a seed solution.

[0042] 2) Enzyme production culture

[0043] Inoculate 10ml of seed liquid into 200mL of enzyme-producing medium, and incubate at 30°C, 200rpm for 36 hours. After the cultivation, centrifuge at 10,000rpm for 10min at 4°C, and collect the supernatant (save at 4°C for later use).

[0044] 3) Degradation of collagen

[0045] Take 100g of cod skin, descale and wash it, cut it into a size of 0.5mm×0.5mm, then add 100mL of the above-mentioned fermentation broth, adjust the pH to 7.5, place it at 37°C, and perform enzymatic hydrolysis at 100rpm for 8 hours. After the enzymolysis was completed, the enzyme was extinguished at 95°C for ...

Embodiment 2

[0046] Embodiment 2: Utilize Bacillus subtilis Col04 fermented liquid to the degradation of fish skin collagen

[0047] Compared with Example 1, the temperature was increased to 37°C during the enzyme-producing culture of the Bacillus subtilis Col04 strain, and the culture time was extended to 48 hours, while other conditions remained unchanged. The conditions for collagen degradation were unchanged. After 8 hours of degradation, the enzymatic solution was centrifuged, and the supernatant was freeze-dried to obtain 13.6 g of off-white powder with a protein content of 92.1% and a yield of 77.71%. Because after prolonging the time of enzyme-producing culture, the activity of collagenase in the fermentation broth increases, resulting in a better effect in degrading collagen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com