Hand-held quick corrosion tester for petroleum pipelines

A rapid corrosion, oil pipeline technology, applied in the direction of weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc., can solve the problems of oil pipeline safety blind spots, slow test response speed, easy deviation of measurement results, etc., to meet the specifications Patrol operation process, fast test response speed, rich human-machine interface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, which is not intended to limit the scope of protection.

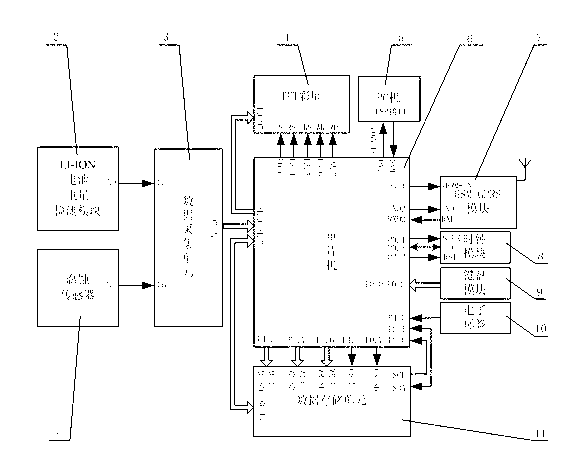

[0028] A handheld rapid corrosion tester for oil pipelines. The tester as figure 1 As shown, it includes corrosion sensor 1, LI-ION battery power detection module 2, data acquisition unit 3, TFT color screen 4, PC 5, single chip microcomputer 6, GSM / GPRS module 7, clock module 8, keyboard module 9, electronic label 10 and data storage unit 11.

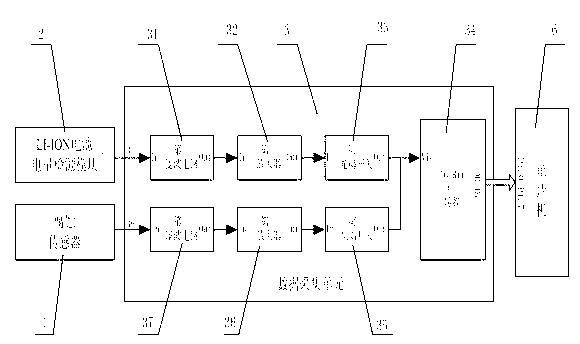

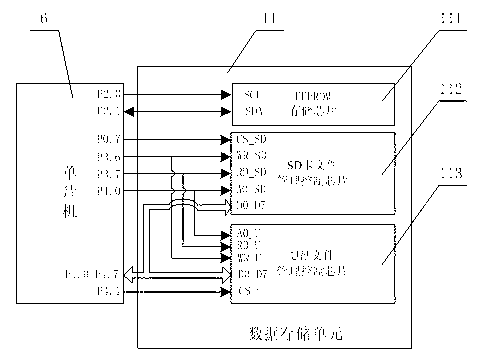

[0029] Such as figure 1 As shown, the signal input terminals 3a, 3b of the data acquisition unit 3 are connected to the output terminal 2a of the LI-ION battery power detection module 2 and the output terminal 1a of the corrosion sensor 1, and the output terminals D0-D7, TFT of the data acquisition unit 3 The ports D0-D7 of the color screen 4 and the ports D0-D7 of the data storage unit 11 are connected to the I / O ports P1.0-P1.7 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com