Unipolar memristor and preparation method thereof

A memristor and unipolar technology, applied in the field of unipolar memristor and its preparation, can solve the problems of ignoring the essential physical properties of the memristor, unable to carry out hardware experiments, and not yet realized commercial production, etc. Achieving, low-cost, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

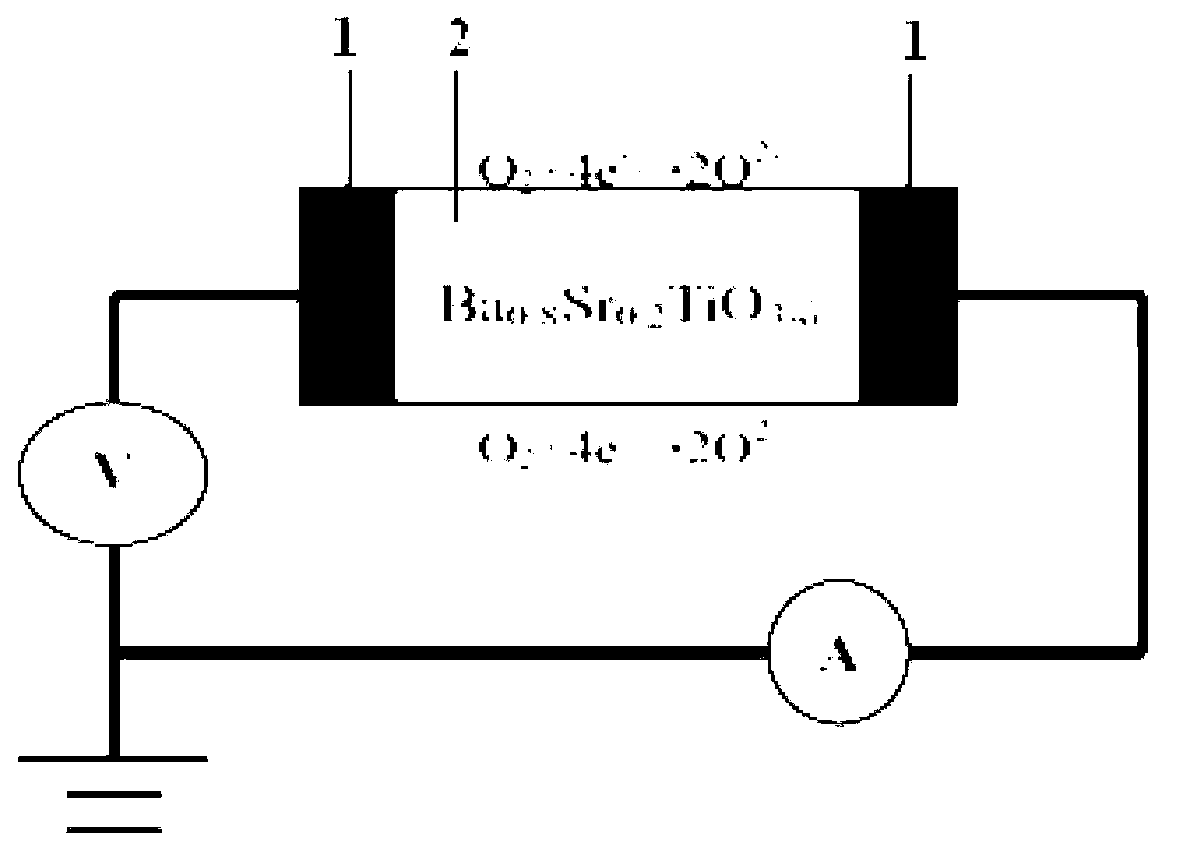

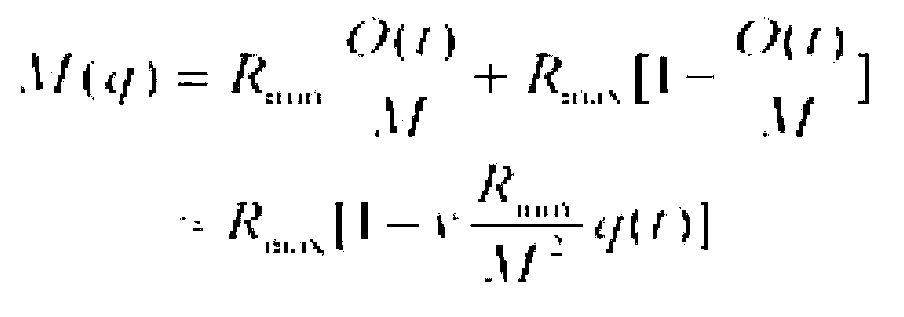

[0033] Such as figure 1 As shown, the unipolar nanometer thin film memristor of the present invention includes two electrodes 1 and a nanometer thin film structure 2 placed therein, figure 2 For the mathematical model of the unipolar nano-film memristor M(q) of the present invention, the preparation method of the nano-film structure 2 is as follows:

[0034] (1) Barium acetate Ba(CH 3 COO) 2 and strontium acetate Sr(CH 3 COO) 2 Mixed at a molar ratio of 9:1, dissolved in acetic acid CH 3 COOH, add appropriate amount of acetylacetone CH 3 COCH 2 COCH 3 As a stabilizer, stir for 15 minutes to obtain a mixture;

[0035] (2) Add butyl titanate Ti(OC 4 h 9 ) 4 , stirred for 30min, filtered;

[0036] (3) Add appropriate amount of glacial acetic acid CH to the filtered solution 3 Dilute COOH to 0.3mol / L, and use it as a precursor after filtration;

[0037] (4) Immerse the substrate in the precursor sol, pull it vertically at a speed of 1cm / s after 30s, and lay it flat ...

Embodiment 2

[0040] In the raw material formula, barium acetate: strontium acetate: butyl titanate = 8:2:10 (molar ratio), and the others are the same as in Example 1.

Embodiment 3

[0042] In the raw material formula, barium acetate: strontium acetate: butyl titanate = 7:3:10 (molar ratio), the stirring time in step (1) is 30min; the amount of acetylacetone added is 5% of the mass of acetic acid; step ( The stirring time in 2) is 40min; the concentration of glacial acetic acid in step (3) is 0.5mol / L; in step (4), the substrate is immersed in the precursor sol, and after 60s, the La, the sol film was dried at 100°C for 10 minutes, the number of repetitions in step (5) was 3, the gel film was heat-treated at 700°C for 10 minutes, and the others were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com