Integrated EMI (electromagnetic interference) filter for optimizing grounded winding layout to improve noise suppression performance

A ground winding and noise suppression technology, which is applied in the field of filters, can solve the problems of poor high-frequency performance and malfunction of filters, and achieve the effects of fewer conductor layers, simple structure, and improved high-frequency suppression capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

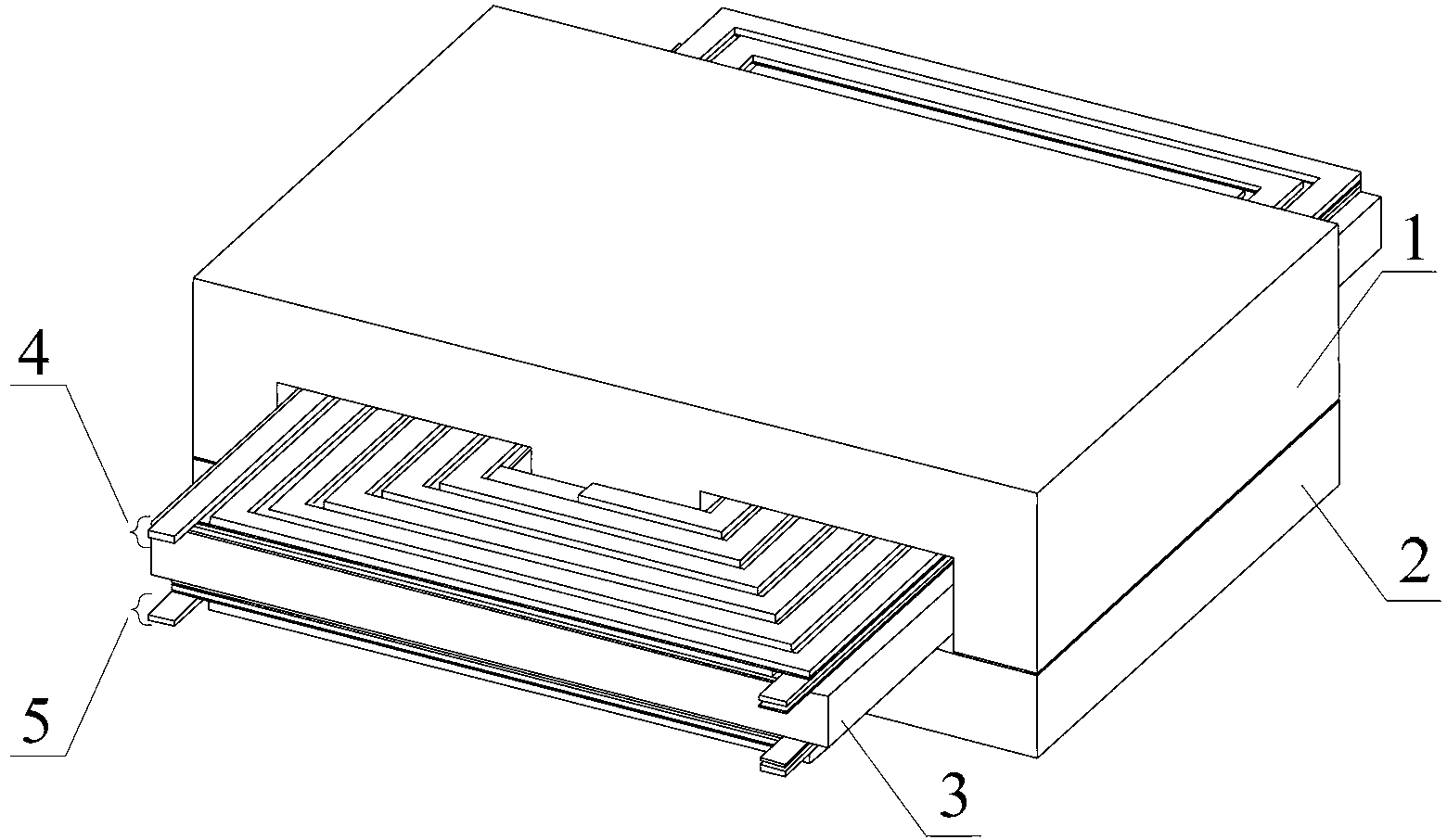

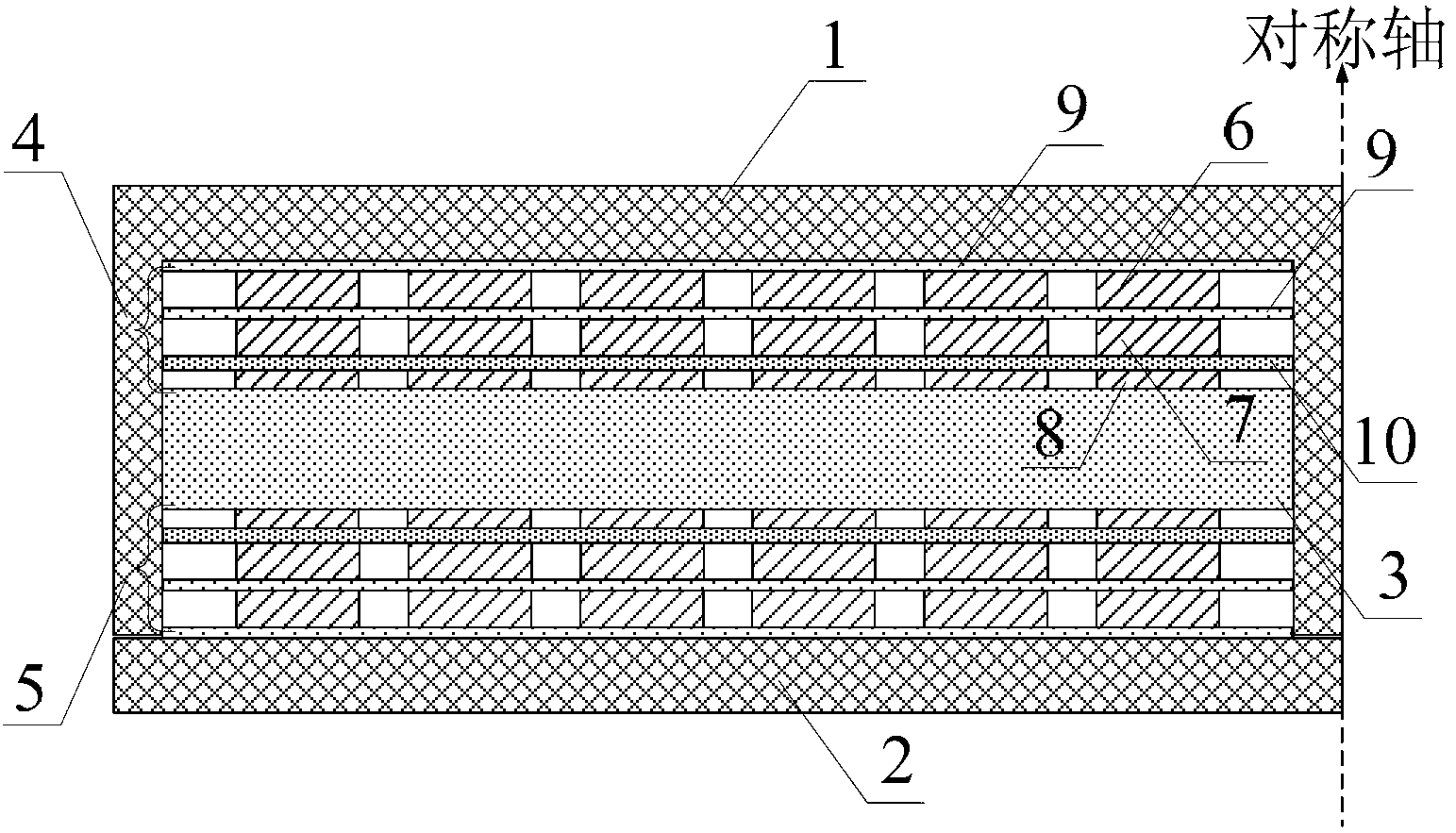

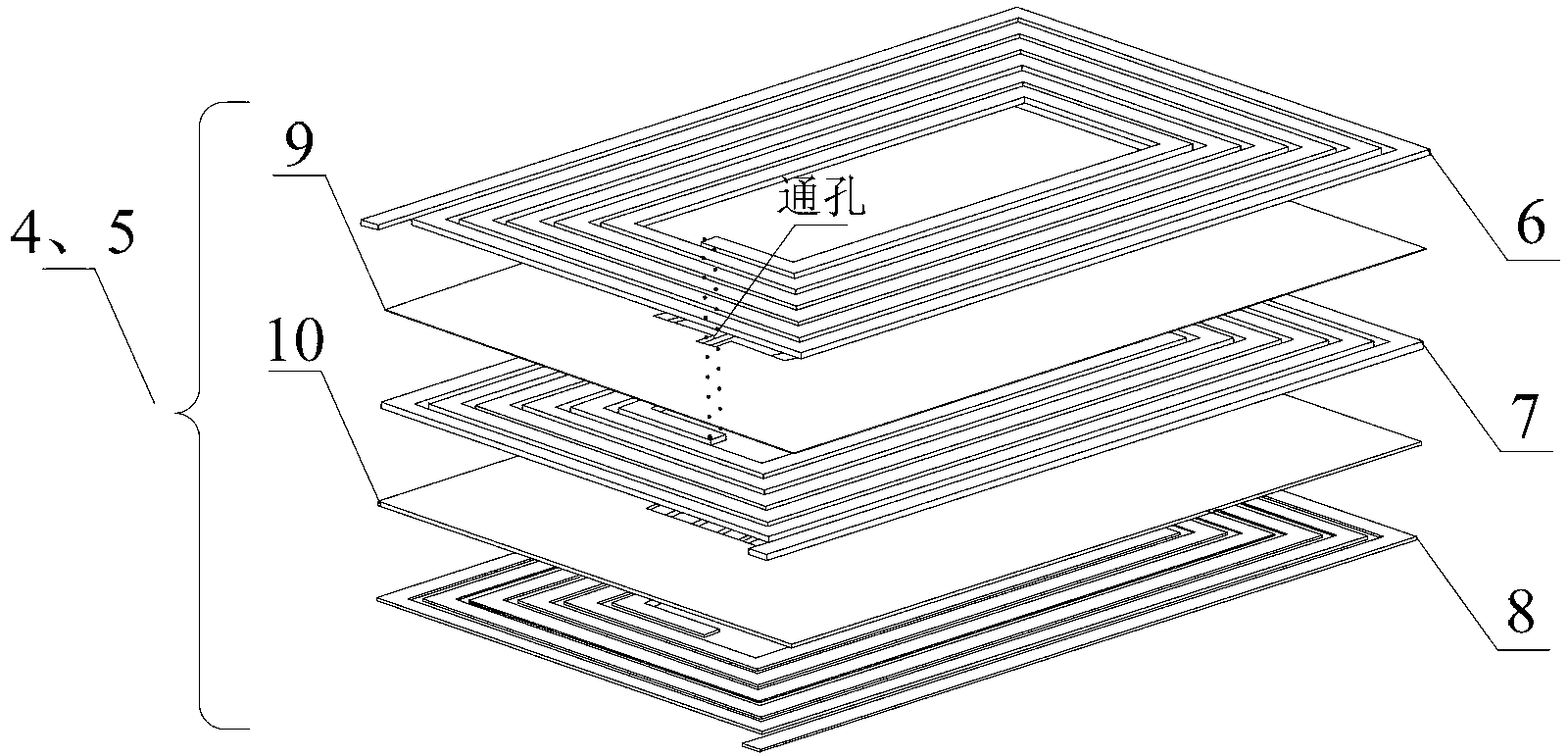

[0039] figure 1 It is a schematic diagram of the overall structure of a traditional integrated EMI filter, including E-type core 1, the first I-type core 2, the specification is E+PLT38-3E5, and the initial relative permeability is 10000, which is used to increase the differential mode leakage inductance The second I-type magnetic core 3 is made of FPC material and has an initial relative magnetic permeability of 9. It also includes two identical common-mode winding units 4 and 5, which are symmetrical on both sides of the differential-mode second I-type magnetic core. place. Considering that the front section of the entire filter is a left-right symmetrical structure, figure 2 A schematic diagram of a left semi-symmetrical cross-section is given. Among them, the common mode winding units 4 and 5 are divided into five layers, which are the upper common mode inductance conductor layer 6, the low dielectric constant insulating layer 9, the lower common mode inductance conduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com