Integrated emi filter with optimized ground winding layout for improved noise rejection

A technology of noise suppression and ground winding, which is applied in the field of filters, can solve the problems of poor high-frequency performance of filters and failure to work normally, and achieve the effects of fewer conductor layers, simple structure, and improved high-frequency suppression capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

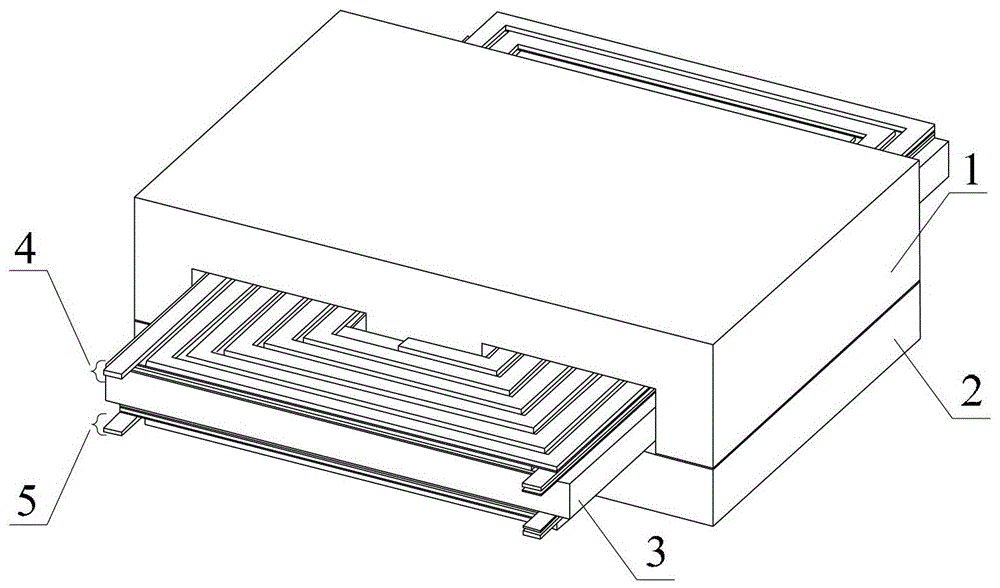

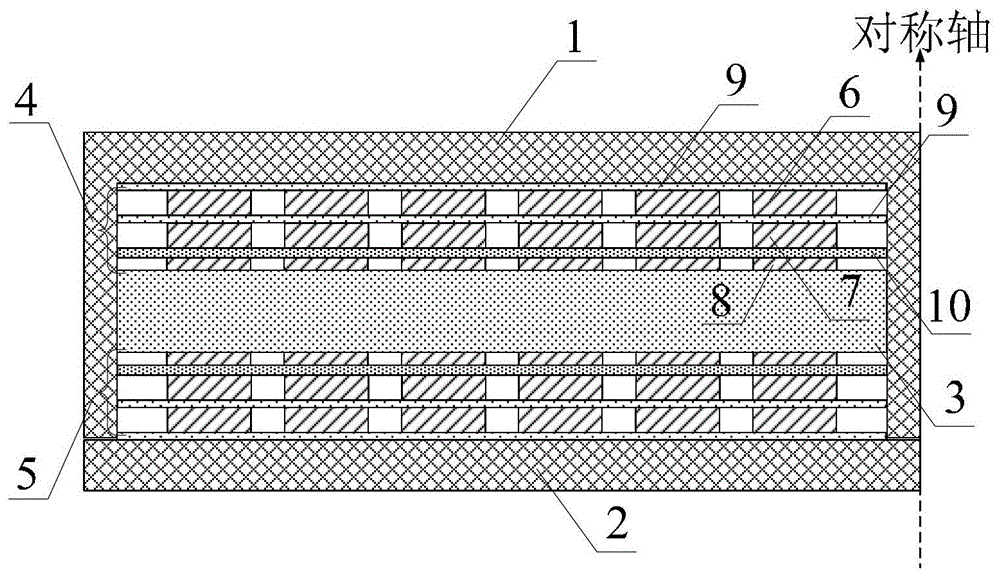

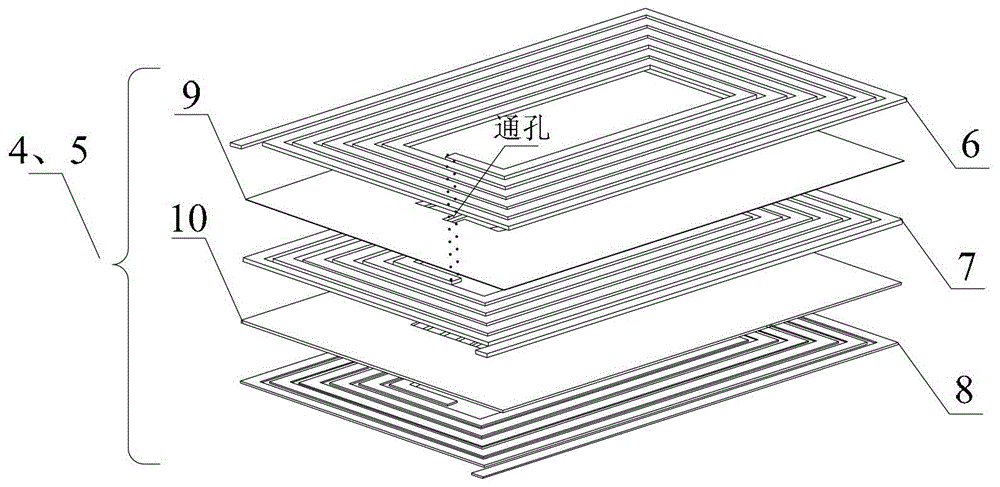

[0039] figure 1 (a) is a schematic diagram of the overall structure of the traditional integrated EMI filter, including E-type core 1, the first I-type core 2, the specification is E+PLT38-3E5, and the initial relative permeability is 10000, which is used to increase the difference The second I-type magnetic core 3 of the mode leakage inductance is made of FPC material, and the initial relative magnetic permeability is 9. It also includes two identical common-mode winding units 4, 5, and the second I-type magnetic core in the differential mode symmetrically placed on both sides. Considering that the front section of the entire filter is a left-right symmetrical structure, figure 2 A schematic diagram of a left semi-symmetrical cross-section is given. Among them, the common mode winding units 4 and 5 are divided into five layers, which are the upper common mode inductance conductor layer 6, the low dielectric constant insulating layer 9, the lower common mode inductive condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com