Bismuth vanadate light catalyst for exposing high-activity crystal face and preparation method for bismuth vanadate light catalyst

A photocatalyst, bismuth vanadate technology, applied in chemical instruments and methods, physical/chemical process catalysts, vanadium compounds, etc., can solve the problems of low photocatalytic activity and insufficient exposure of high-activity crystal faces, and achieve good repeatability. , Good visible light response performance, the effect of short reaction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The first step: take 2.5mmol Bi(NO 3 ) 3 ·5H 2 Dissolve O in 50ml of dilute nitric acid solution (2M), add 0.5g of sodium dodecylsulfonate, stir for 60min to dissolve completely, and record it as solution A.

[0040] The second step: take 2.5mmol NH 4 VO 3 Dissolve in 50ml dilute ammonia solution (2M), stir for 60min to dissolve completely, and record it as solution B.

[0041] Step 3: Add solution A to solution B under vigorous stirring, continue stirring for 30 minutes, then slowly adjust the pH to 7 with ammonia solution, and continue stirring for 30 minutes.

[0042] Step 4: Transfer the obtained mixed solution into a crystallization kettle with a polytetrafluoroethylene liner, keep it at 180° C. for 24 hours, and cool it down to room temperature naturally.

[0043] Step 5: centrifuge, wash with deionized water three times and absolute ethanol three times, and dry at 80° C. for 8 hours to obtain bismuth vanadate nanoparticles.

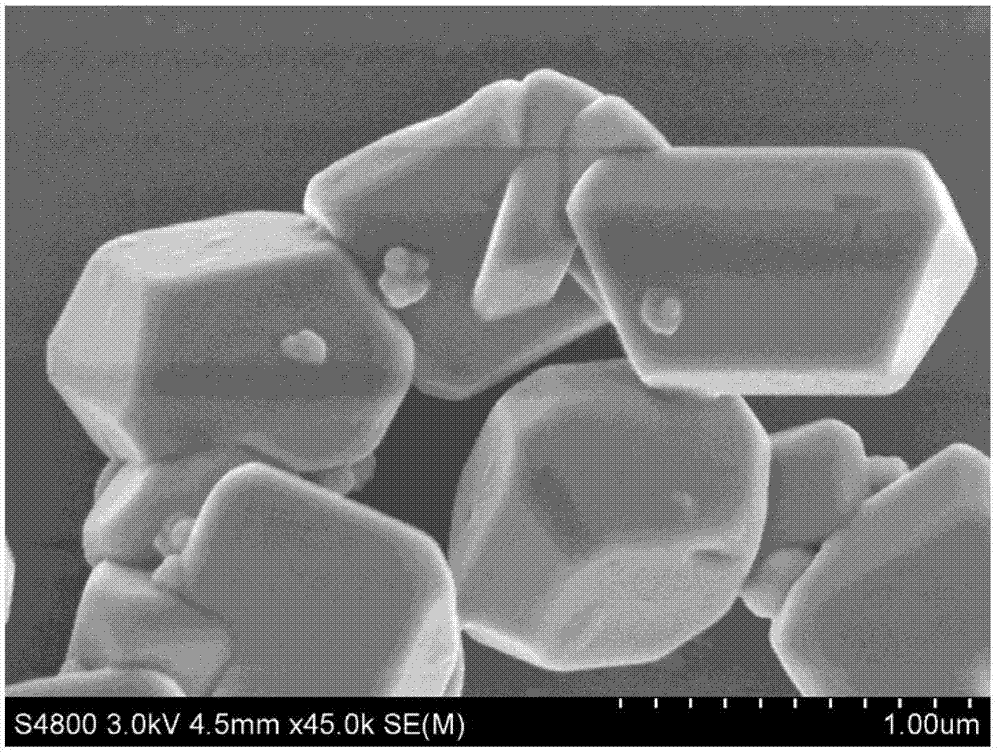

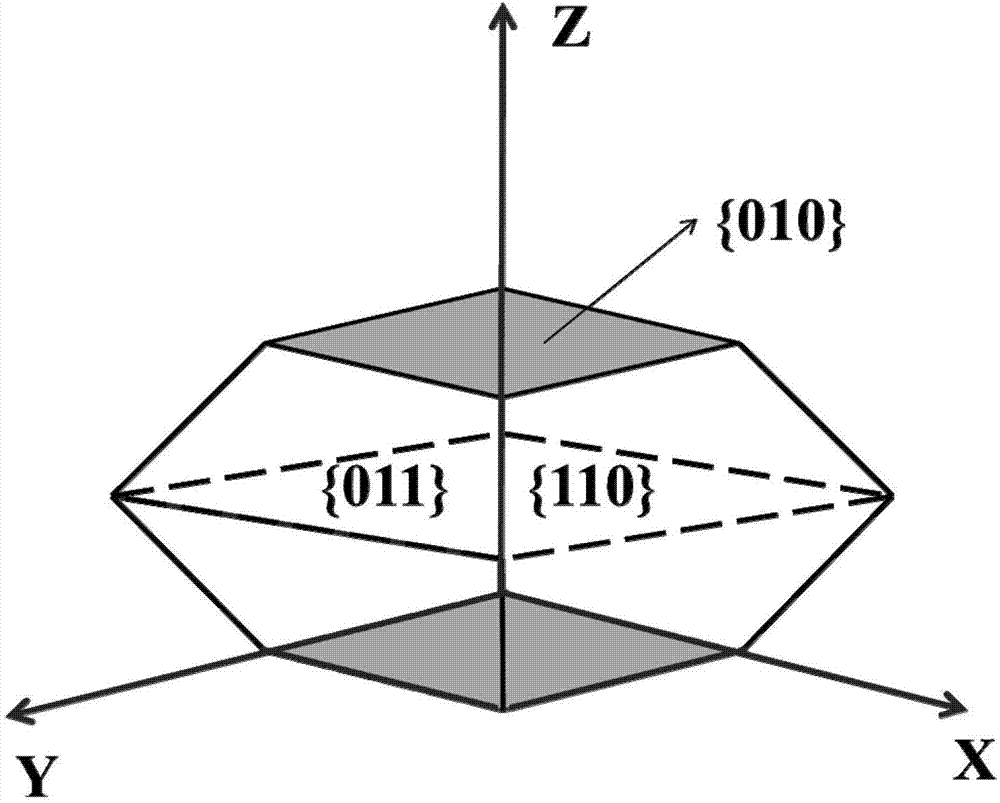

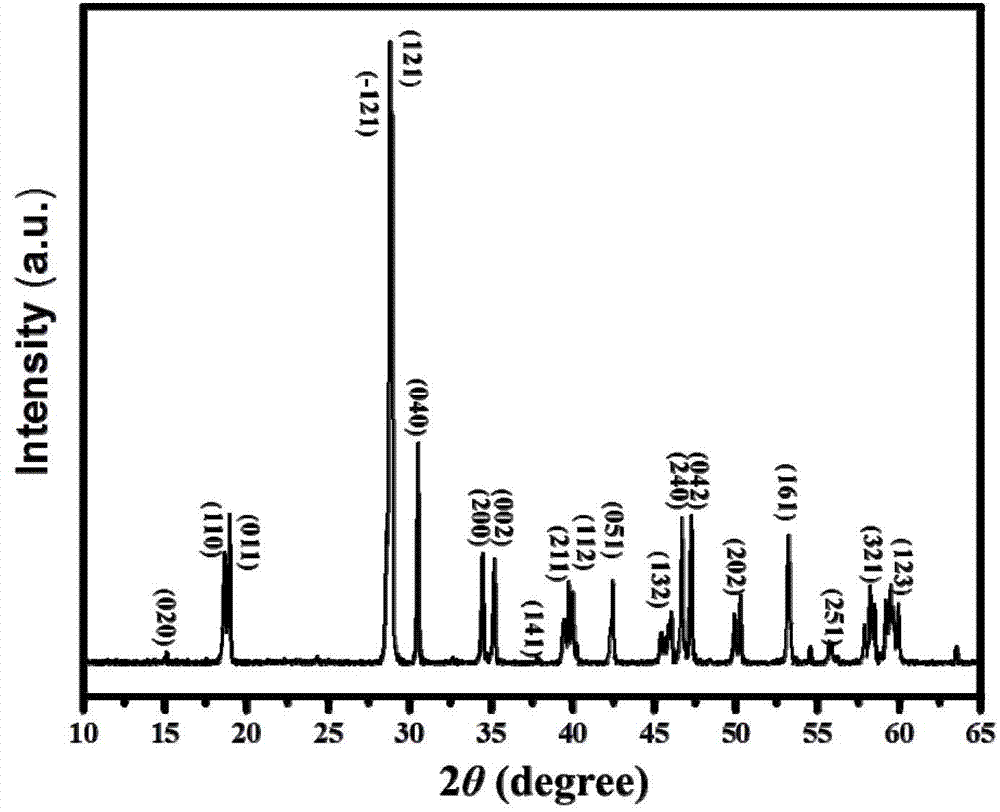

[0044] Depend on figure 1 It c...

Embodiment 2

[0049] The first step: take 2.5mmol Bi(NO 3 ) 3 ·5H 2 Dissolve O in 60ml of dilute nitric acid solution (4M), add 0.65g of sodium dodecylsulfonate, stir for 30min to dissolve completely, and record it as solution A.

[0050] The second step: take 2.5mmol NH 4 VO 3 Dissolve in 60ml of dilute ammonia solution (4M), stir for 30min to dissolve completely, and record it as solution B.

[0051] Step 3: Add solution A to solution B under vigorous stirring, continue stirring for 30 minutes, then slowly adjust the pH to 8 with ammonia solution, and continue stirring for 120 minutes.

[0052] Step 4: Transfer the obtained mixed solution to a crystallization kettle with a polytetrafluoroethylene liner, keep it at 200° C. for 48 hours, and cool it down to room temperature naturally.

[0053] Step 5: centrifugation, washing with deionized water three times and absolute ethanol three times respectively, and drying at 100° C. for 12 hours to obtain bismuth vanadate nanoparticles.

[00...

Embodiment 3

[0057] The first step: take 2.5mmol Bi(NO 3 ) 3 ·5H 2 Dissolve O in 40ml of dilute nitric acid solution (1M), add 0.45g of sodium dodecylsulfonate, stir for 40min to dissolve completely, and record it as solution A.

[0058] The second step: take 2.5mmol NH 4 VO 3 Dissolve in 40ml of dilute ammonia solution (1M), stir for 40min to dissolve completely, and record it as solution B.

[0059] Step 3: Add solution A to solution B under vigorous stirring, continue stirring for 30 minutes, then slowly adjust the pH to 6.5 with ammonia solution, and continue stirring for 60 minutes.

[0060] Step 4: Transfer the obtained mixed solution to a crystallization kettle with a polytetrafluoroethylene liner, keep it at 160° C. for 12 hours, and cool it down to room temperature naturally.

[0061] Step 5: centrifuge, wash three times with deionized water and three times with absolute ethanol, and dry at 60° C. for 6 hours to obtain bismuth vanadate nanoparticles.

[0062] The bismuth van...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com