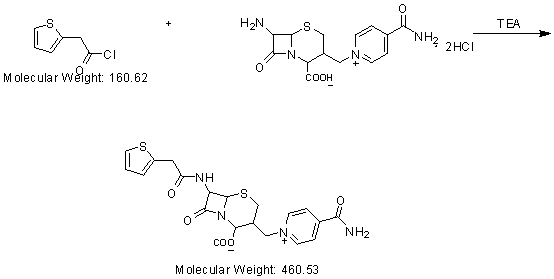

Cefalonium preparation method

A technology of ceflonine and reaction solvent, which is applied in the field of preparation of compound ceflonine and achieves the effects of high yield, simple operation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

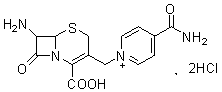

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 10g of 7-IACA, add 100mL of water, adjust the pH to 6-7 with sodium bicarbonate, stir, cool with ice water to 0°C, add 5.7ml of thiopheneacetyl chloride dropwise, control the rate of addition so that the temperature is kept at about 0°C, add dropwise thiophene acetyl chloride At the same time as the acid chloride, sodium bicarbonate solution was added dropwise, and the pH was controlled at 6-7. After the dropwise addition, the reaction was stirred for 0.5h, filtered, and the filter cake was washed with dichloromethane, then washed with water, washed with acetone, and dried under reduced pressure to obtain 4.4g of the product. The yield was 38.2%, purity 99%.

Embodiment 2

[0030] Weigh 10g of 7-IACA, add 100mL of water, adjust the pH to 6-7 with sodium acetate, stir, cool with ice water to 0°C, add 5.7ml of thiopheneacetyl chloride dropwise, control the rate of addition so that the temperature is kept at about 0°C, add dropwise of thiopheneacetyl chloride At the same time, sodium acetate solution was added dropwise, the pH was controlled to 6-7, the dropwise addition was completed and the reaction was stirred for 0.5h, filtered, the filter cake was washed with dichloromethane, then washed with water, washed with acetone, and dried under reduced pressure to obtain 4.6g of the product, with a yield of 40%. , 99% purity.

Embodiment 3

[0032] Weigh 70g of 7-IACA, add 150ml of water, 250ml of dimethylformamide (hereinafter referred to as DMF), stir, cool down to -2°C, add potassium carbonate to adjust the pH to 6-7, then add 54g of thiopheneacetyl chloride dropwise. Control the temperature between -2-15°C, add potassium carbonate solution dropwise at the same time, control the pH6-7, stir and react for 2h after the dropwise addition, add 50ml3N hydrochloric acid, adjust the pH1-2, add 500ml dichloromethane for extraction, The organic phase was washed twice with dichloromethane, dimethylformamide was dissolved in dichloromethane, and water was forced out at the same time, and sodium bicarbonate solution was added to adjust the pH to 6-7, stirred and crystallized, and dried to obtain 34g of the product. The purity is 99.3%, and the yield is 42%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com