Active carbon fiber and graded porous Ni-Ni3P/active carbon fiber composite material as well as preparation and application of two

A technology of activated carbon fibers and composite materials, applied in the directions of alkali metal compounds, water/sewage treatment, chemical instruments and methods, etc., can solve problems such as no activated carbon fibers, and achieve good catalytic effect, high efficiency and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

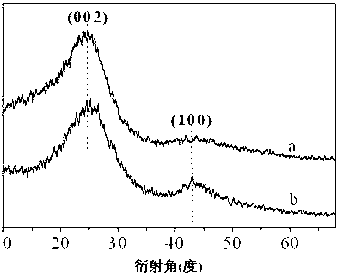

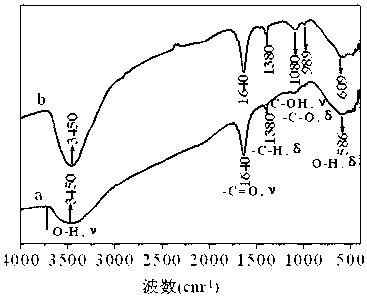

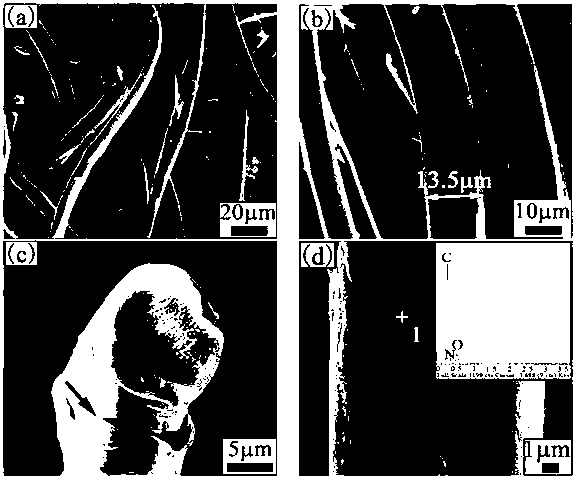

[0064] The cocoons were boiled in boiling water at 100 °C for 30 min, then cooled in cold water and manually drawn, and the obtained silk was dried in an oven at 80 °C to obtain mulberry silk with sericin removed. Formulated with a mass fraction of 10% (NH 4 ) 2 HPO 4 solution, according to 1 g mulberry silk with 30 ml (NH 4) 2 HPO 4 The proportion of the solution was dipped, the dipping time was 12 h, and then it was dried and dried in an oven at 80 °C. The mulberry silk was pre-oxidized in a muffle furnace at 250 °C for 1 h to obtain pre-oxidized silk. Pre-oxygen wire in vacuum tube furnace N 2 Under the protection, it was heated to 600 °C at a heating rate of 5 °C / min, kept for 60 min, and then carbonized. After the temperature dropped to room temperature, the nitrogen flow was cut off, and the carbonized material was taken out. Put the prepared carbon material in a vacuum tube furnace N 2 Program temperature roasting under protection: heating to 900 °C at a heatin...

Embodiment 2

[0066] The cocoons were boiled in boiling water at 100 °C for 30 min, then cooled in cold water and manually drawn. The obtained silk was dried in an oven at 80 °C to obtain the mulberry silk required for the experiment. Formulated with a mass fraction of 10% (NH 4 ) 2 HPO 4 solution, according to 1 g mulberry silk with 30 ml (NH 4 ) 2 HPO 4 The proportion of the solution was dipped for 12 h, and then dried in an oven at 80 °C. Pre-oxidized in a muffle furnace at 250 °C for 1 h to obtain pre-oxidized filaments. Pre-oxygen wire in vacuum tube furnace N 2 Under the protection, it was heated to 600 °C at a heating rate of 5 °C / min, kept for 60 min, and then carbonized. After the temperature dropped to room temperature, the nitrogen flow was cut off, and the carbonized material was taken out. Put the prepared carbon material SCF into the vacuum tube furnace N 2 Program temperature roasting under protection: heating to 900 °C at a heating rate of 5 °C / min, cut off the ...

Embodiment 3

[0068] The cocoons were boiled in boiling water at 100 °C for 30 min, then cooled in cold water and manually drawn. The obtained silk was dried in an oven at 80 °C to obtain the mulberry silk required for the experiment. Formulated with a mass fraction of 10% (NH 4 ) 2 HPO 4 solution, according to 1 g mulberry silk with 30 ml (NH 4 ) 2 HPO 4 The proportion of the solution was dipped for 12 h, and then dried in an oven at 80 °C. Pre-oxidized in a muffle furnace at 250 °C for 1 h to obtain pre-oxidized filaments. Pre-oxygen wire in vacuum tube furnace N 2 Under the protection, it was heated to 600 °C at a heating rate of 5 °C / min, kept for 60 min, and then carbonized. After the temperature dropped to room temperature, the nitrogen flow was cut off, and the carbonized material was taken out. Put the prepared carbon material SCF into the vacuum tube furnace N 2 Program temperature roasting under protection: heating to 900 °C at a heating rate of 5 °C / min, cut off the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com