Fortified young bird feed

A technology of young chicks and raw materials, which is applied in the field of laying hen feed, can solve the problems that the egg production performance cannot give full play to the characteristics of the breed, the weight of reserve chickens is large, and the chickens lose hair, etc., so as to enhance the immune function and disease resistance of laying hens, and easily Effect of food intake and promotion of absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

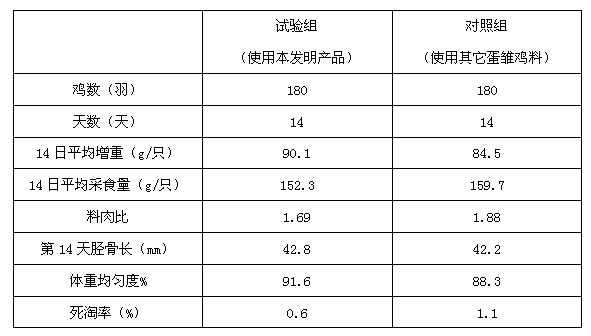

Examples

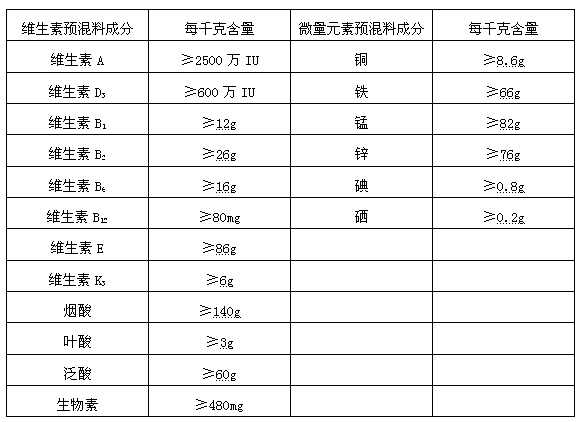

Embodiment 1

[0037] Take 57.02kg of corn, 25.32kg of soybean meal, 4.2kg of cottonseed protein, 3kg of corn gluten meal, 2.4kg of ground floor, 2kg of vegetable oil, 1.8kg of bentonite, 0.24kg of table salt, 1.4kg of stone powder, 1.46kg of Dibasic calcium phosphate, 0.16kg 50% choline chloride, 0.17kg rice bran, 0.3kg L-lysine hydrochloride, 0.17kg DL-methionine, 0.05kg antioxidant, 0.14kg immune booster agent (yeast cell wall extract), 0.05kg of probiotics (Bacillus subtilis, the number of viable bacteria ≥ 10 billion / g), 0.08kg of trace element premix and 0.04kg of vitamin premix, all the raw materials After crushing and passing through a mesh sieve, put it into a mixer and mix it. The mixed powder is packaged and filled after passing through a feeding screw, a conditioner, a granulator, a cooler, a crusher, and a finished product warehouse, and is made into 100kg with a particle size of 1.0 -1.5mm granular feed.

Embodiment 2

[0039] Take 58.46kg of corn, 23.2kg of soybean meal, 4.8kg of cottonseed protein, 4kg of corn gluten meal, 2.1kg of ground floor, 1.4kg of vegetable oil, 1.8kg of bentonite, 0.24kg of table salt, 1.5kg of stone powder, 1.4 kg of calcium hydrogen phosphate, 0.14kg of 50% choline chloride, 0.12kg of rice bran, 0.34kg of L-lysine hydrochloride, 0.17kg of DL-methionine, 0.05kg of antioxidants, 0.12kg of immune Enhancer (yeast cell wall extract), 0.05kg of probiotics (Bacillus subtilis, the number of viable bacteria ≥ 10 billion / g), 0.08kg of trace element premix and 0.03kg of vitamin premix, all ingredients The raw materials are crushed and passed through a mesh sieve and put into a mixer for mixing. The mixed powder is packaged and filled after passing through a feeding screw, a conditioner, a granulator, a cooler, a crusher, and a finished product warehouse, and the particle size of 100kg is 1.0-1.5mm granular feed.

Embodiment 3

[0041] Take 57.27kg of corn, 24.32kg of soybean meal, 4.6kg of cottonseed protein, 3.4kg of corn gluten powder, 2.4kg of ground floor, 2.2kg of vegetable oil, 1.6kg of bentonite, 0.24kg of table salt, 1.4kg of stone powder, 1.5kg of calcium hydrogen phosphate, 0.14kg of 50% choline chloride, 0.1kg of rice bran, 0.32kg of L-lysine hydrochloride, 0.17kg of DL-methionine, 0.05kg of antioxidants, 0.12kg of Immunopotentiator (yeast cell wall extract), 0.05kg of probiotics (Bacillus subtilis, the number of viable bacteria ≥ 10 billion / g), 0.08kg of trace element premix and 0.04kg of vitamin premix, all The ingredients are crushed and passed through a mesh sieve and put into a mixer for mixing. The mixed powder is packaged and filled after passing through a feeding screw, a conditioner, a granulator, a cooler, a crusher and a finished product warehouse to make a particle size of 100kg. 1.0-1.5mm granular feed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com