Method for preparing nanometer silicon dioxide material at normal temperature

A nano-silica, conditional technology, applied in the direction of silica, silicon oxide, nanotechnology, etc., can solve the problems of nano-silica production impact, strict equipment requirements, and low apparent density, and achieve good application prospects, The effect of low cost and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

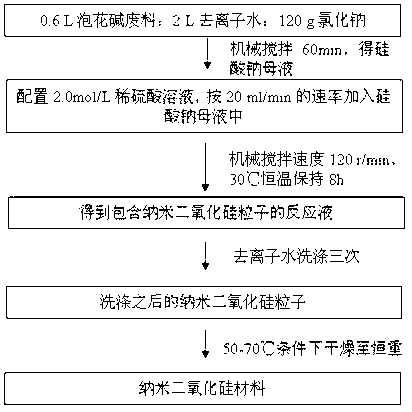

Method used

Image

Examples

Embodiment 1

[0031] (1) Sodium sodium chloride and 120g sodium chloride were dissolved in deionized water to obtain a sodium silicate mother liquor, and 98% concentrated sulfuric acid was configured into a 2.0mol / L sulfuric acid solution to obtain an acid mother liquor; wherein the sodium silicate modulus was 3.8, the mass percent concentration of sodium silicate in sodium silicate mother liquor is 30%.

[0032] (2) Put the mother liquor of sodium silicate into a 5L reaction kettle, keep it warm at 30°C, and add the mother liquor of sulfuric acid dropwise at a speed of 20mL / min at a stirring speed of 130r / min until pH=5.0, and keep stirring at 30°C Keep for 6h;

[0033] (3) The obtained product is then separated, washed, and dried at 50° C. for 6 hours to obtain nano-silica particles.

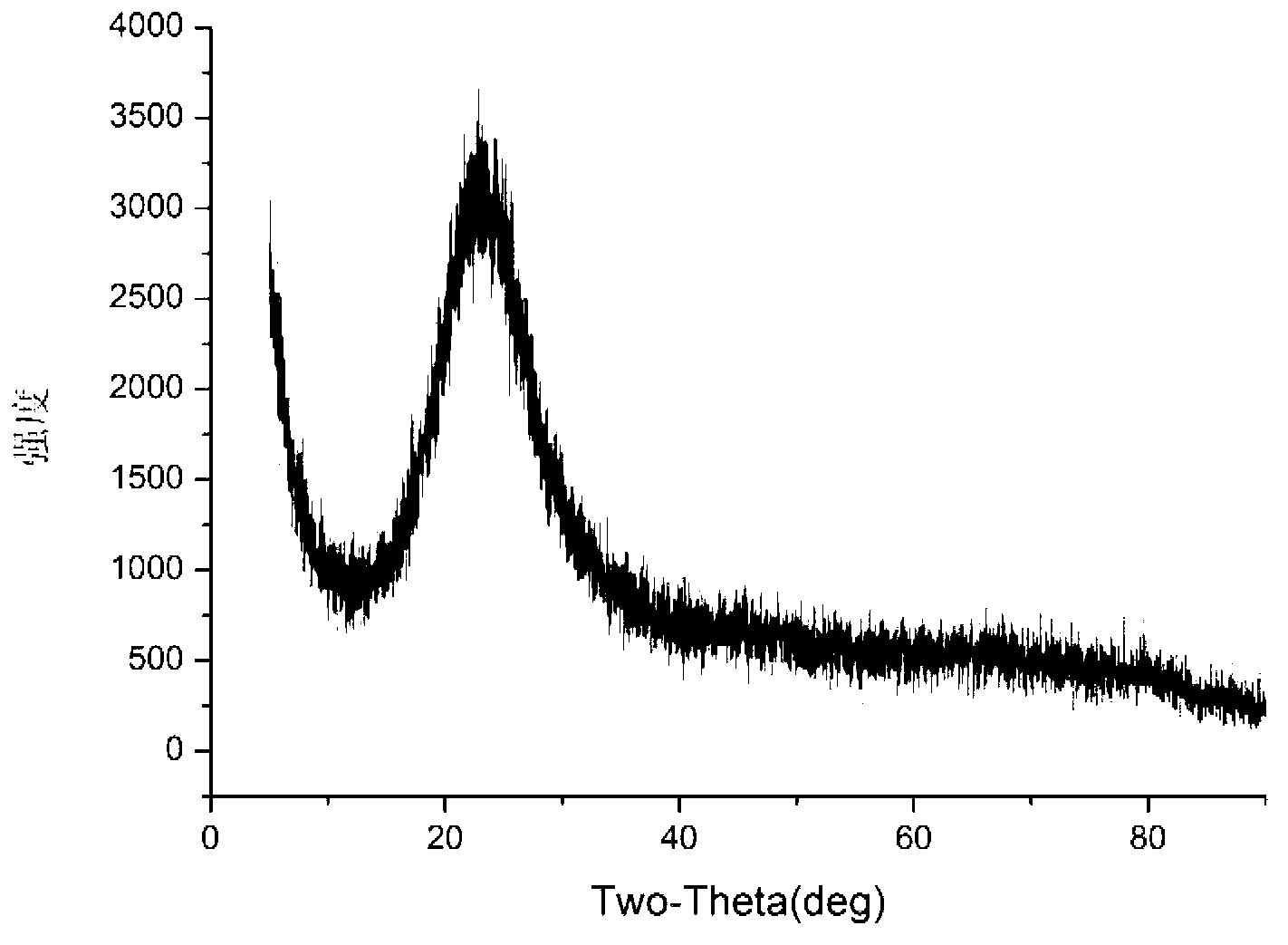

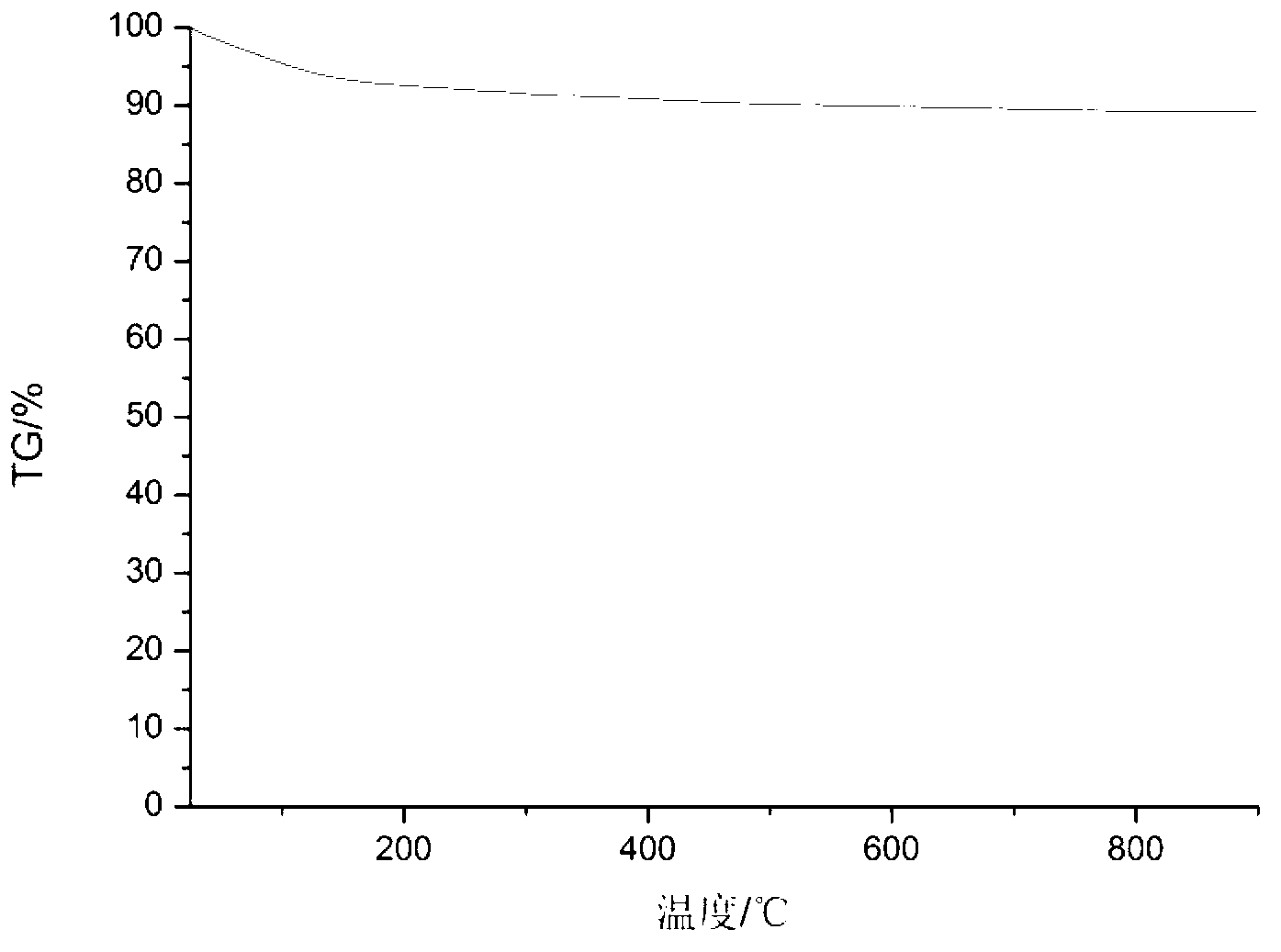

[0034] The transmission electron microscope picture of the nano silicon dioxide particle that scheme 1 makes sees Figure 5 , the average particle size estimated from the figure is 16nm. The X-ray diffra...

Embodiment 2

[0036] (1) Sodium sodium chloride and 120g sodium chloride were dissolved in deionized water to obtain a sodium silicate mother liquor, and 98% concentrated sulfuric acid was configured into a 2.0mol / L sulfuric acid solution to obtain an acid mother liquor; wherein the sodium silicate modulus was 4.0, the mass percentage concentration of sodium silicate in sodium silicate mother liquor is 20%.

[0037] (2) Put the sodium silicate mother liquor into a 5L reaction kettle, keep it warm at 30°C, and add the sulfuric acid mother liquor dropwise at a speed of 10mL / min at a stirring speed of 120r / min until pH=6.0, and keep stirring at 30°C keep 8h;

[0038] (3) The obtained product is then separated, washed, and dried at 60° C. for 4 hours to obtain nano-silica particles.

[0039] The transmission electron microscope picture of the nano silicon dioxide particle that scheme 2 makes is shown in Image 6 , the average particle size estimated from the figure is 23nm, and the BET specif...

Embodiment 3

[0041] (1) Sodium sodium chloride and 120g sodium chloride were dissolved in deionized water to obtain a sodium silicate mother liquor, and 98% concentrated sulfuric acid was configured into a 2.0mol / L sulfuric acid solution to obtain an acid mother liquor; wherein the sodium silicate modulus was 3.8, the mass percentage concentration of sodium silicate mother liquor is 10%.

[0042] (2) Put the sodium silicate mother liquor into a 5L reaction kettle, keep it warm at 30°C, and add the sulfuric acid mother liquor dropwise at a speed of 20mL / min at a stirring speed of 120r / min until pH=7.0, and keep stirring at 35°C keep 8h;

[0043] (3) The obtained product is then separated, washed, and dried at 70° C. for 4 hours to obtain nano-silica particles.

[0044] The transmission electron microscope picture of the nano silicon dioxide particle that scheme 3 makes sees Figure 7 , the average particle size estimated from the figure is 43nm, and the BET specific surface area is 174m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com