Non-phosphorus environment-friendly softening water corrosion inhibitor

A kind of corrosion inhibitor and environmental protection technology, applied in the field of soft water closed circulation system, can solve the problems of high concentration of corrosion inhibitor dosing, high water treatment cost, high water quality requirements, and achieve good corrosion inhibition effect, long effective time, dissolution high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A phosphorus-free environment-friendly soft water corrosion inhibitor is characterized in that the corrosion inhibitor is prepared by the following method,

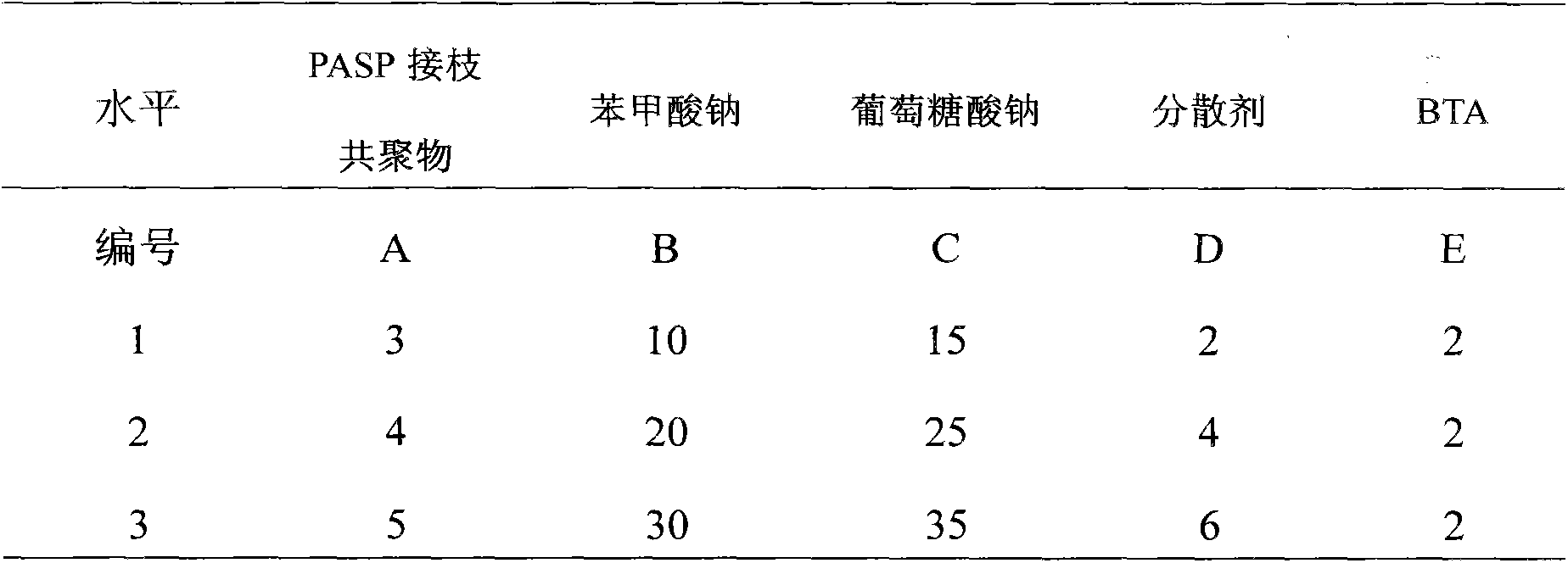

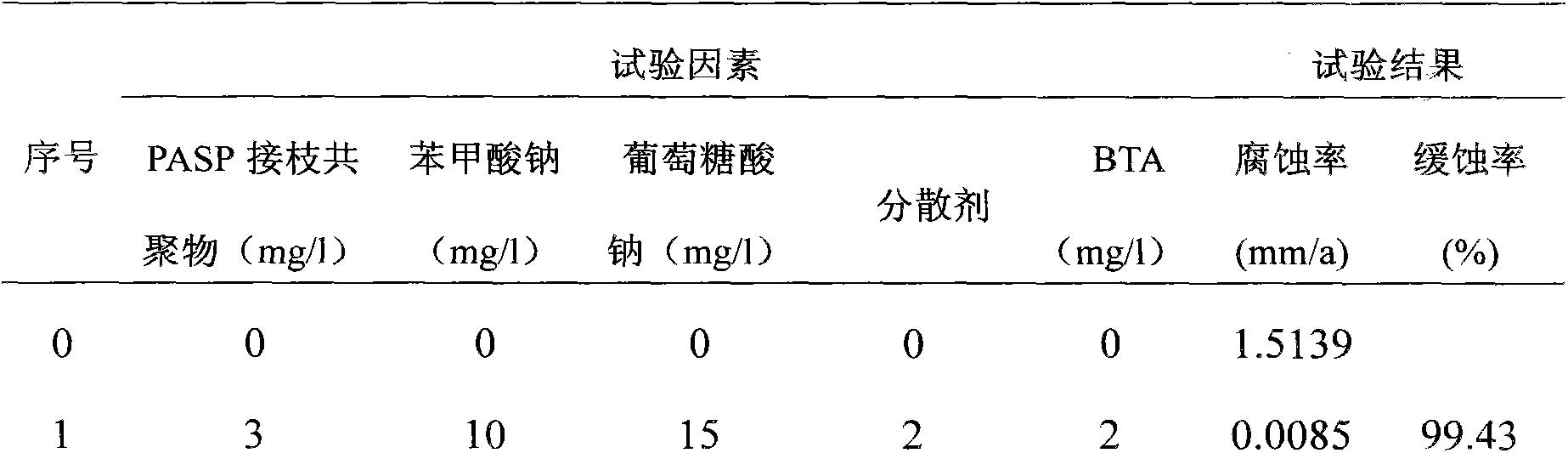

[0026] Dissolve 20-40% sodium gluconate and 20-45% sodium benzoate in water, then add 5-10% polyaspartic acid graft copolymer containing hydroxyl, stir well and then add 1-3% benzotriazole and continue to stir, finally add 5-10% dispersant and stir evenly.

[0027] The benzotriazole can also be mercaptobenzothiazole, and the concentration of the medicament used remains unchanged. The chemical concentration is 2ppm, which is not used as a test factor for metal corrosion and corrosion inhibition.

[0028] The dispersant is propylene tricarboxylic acid-allyl sulfonic acid copolymer,

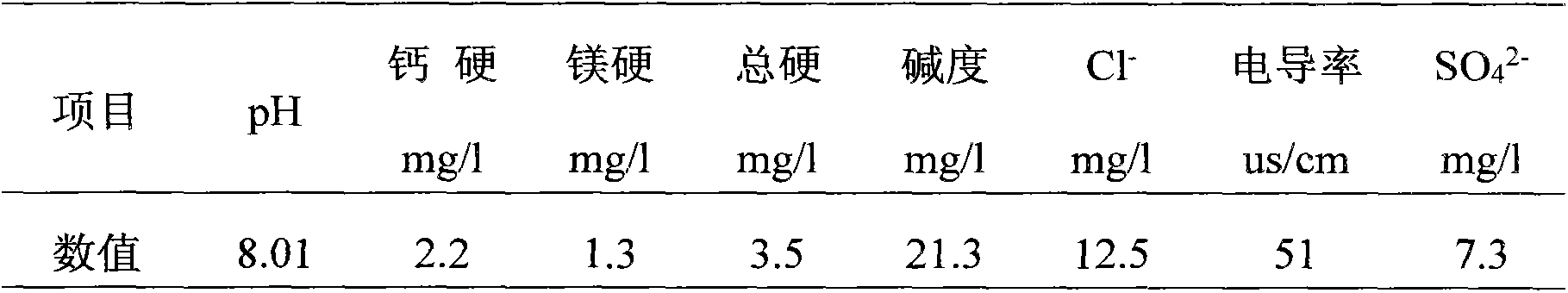

[0029] The corrosion test adopts the determination of the corrosion inhibition performance of water treatment agents-rotary coupon method, this method is the national standard GB / T18175-2000 of the People's Republic of China, the instr...

Embodiment 1

[0039] The 150-ton converter oxygen lance closed circulation system, the soft water is the reverse osmosis softened water produced by the power plant, the temperature of the incoming water is 40 degrees, and the temperature of the return water is 50 degrees. The cooling equipment adopts a plate heat exchanger. The formula is polyaspartic acid graft copolymer containing hydroxyl group 5ppm, sodium gluconate 25ppm, sodium benzoate 25ppm, dispersant 3ppm, benzotriazole or mercaptobenzothiazole 2ppm, this formula is in the converter closed loop system It has been used for 4 years, the content of iron ions in the circulating water is less than 1mg / l, the turbidity is less than 10mg / l, the system runs stably, there are four groups of coupons in the circulating water system, the selected time is 3 months and 6 months, after The monitoring results show that the surface of the coupons is smooth, free of pitting, scale and slime, and the corrosion rate of the coupons is between 0.0036-0....

Embodiment 2

[0041]The 2200m3 blast furnace adopts a soft water closed circulation system. The soft water used is ion exchange resin softened water. The soft water corrosion inhibitor used is the soft water corrosion inhibitor of the present invention. The formula is 3 ppm of hydroxyl-containing polyaspartic acid graft copolymer, glucose sodium benzoate 30ppm, sodium benzoate 20ppm, dispersant 4ppm, benzotriazole or mercaptobenzothiazole 2ppm. The blast furnace was put into operation in 2008, and the iron ion content in the soft water circulation system of the blast furnace was gradually reduced from 8-9mg / l to 1-2mg / l after dosing, reaching the industry standard. During operation, there are 6 groups of coupons hanging in the pipeline. From the observation of the taken out coupons, there is no obvious corrosion phenomenon on the surface, which is almost the same as the initial state. The surface is metallic and the corrosion rate is 0.0040-0.0071mm / Between a and fully comply with the prov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com