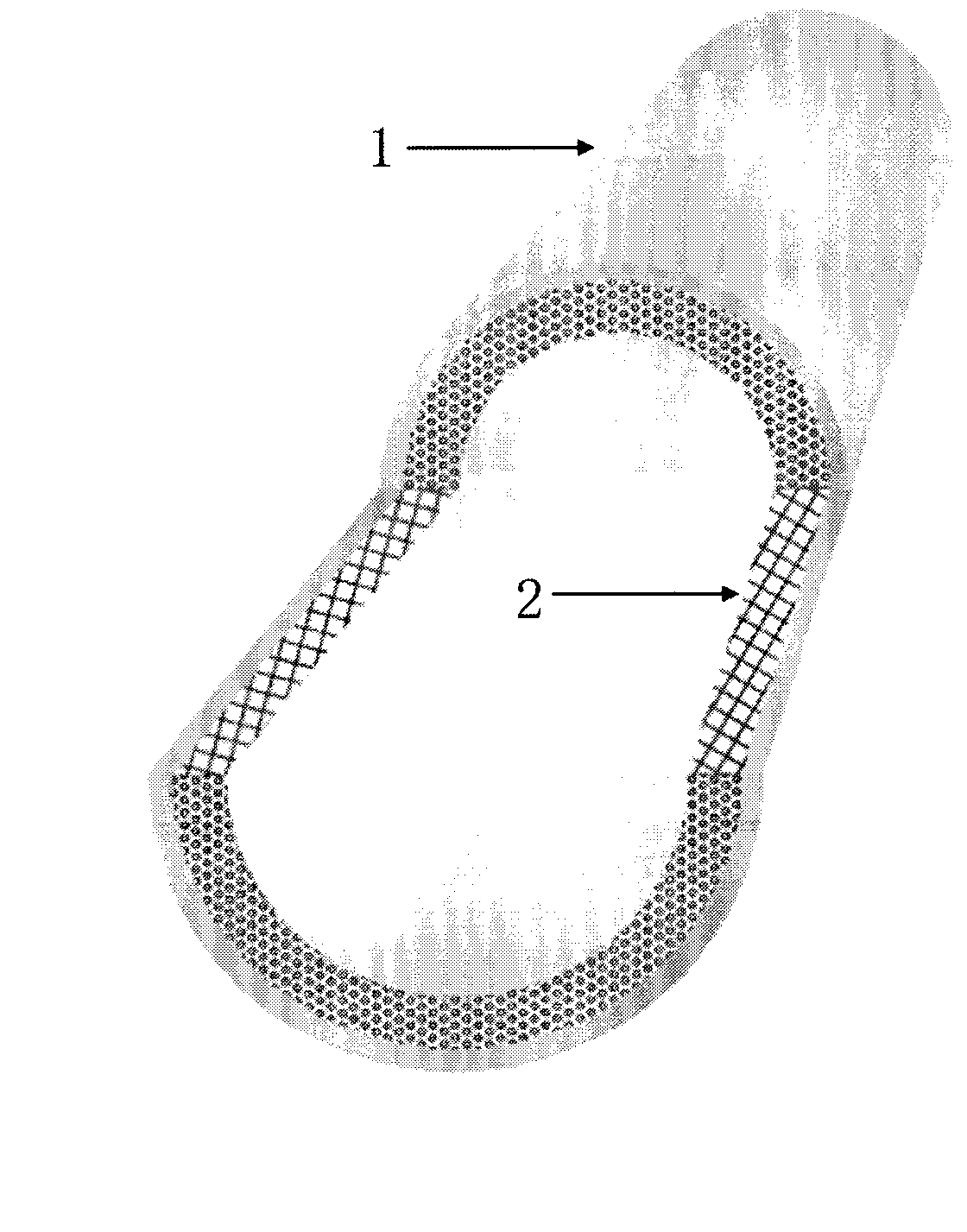

High-strength, high-elasticity and degradable artificial cardiovascular stent and preparation method thereof

A high-elasticity, high-strength technology, applied in braids, medical science, fiber types, etc., can solve problems such as low strength and uncontrollable degradation, and achieve the effect of inhibiting bacteria, high strength, and high elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) The polylactic acid-chitosan fiber with a fineness of 100dtex (the mass ratio of polylactic acid and chitosan is 50:50) is pulled out from the spool at a speed of 10m / min after being twisted three times and passed through a high-speed braiding machine The guide wheel guides to the weaving point and is woven into a hollow braided rope;

[0030] (2) Put the hollow braided rope prepared by step (1) on the outside of a stainless steel wire with a diameter of 3mm and a length of 50cm, and process the braided rope with a drum type microwave continuous heater; the microwave output power is 450w, and the heating temperature is 100°C ;

[0031] (3) Polyglycolic acid-chitosan (the mass ratio of polyglycolic acid and chitosan is 50:50) and polyethylene glycol (molecular weight is 2000) is dissolved in tetrahydrofuran with 40:8 (mass ratio), The concentration of the solution formed is 50%;

[0032] (4) Coating the casting solution prepared in step (3) on the surface of the ho...

Embodiment 2

[0034] (1) The polylactic acid-chitosan fiber with a fineness of 300dtex (the mass ratio of polylactic acid and chitosan is 90:10) is twisted twice and pulled out from the bobbin at a speed of 1m / min. The guide wheel of the machine guides to the weaving point and weaves into a hollow braided rope;

[0035] (2) the hollow braided rope that step (1) is made is worn on diameter 0.1mm, and length is outside the stainless steel wire of 30cm, and process braided rope with drum type microwave continuous heater; Microwave output power is 200w, and heating temperature is 150 ℃;

[0036] (3) Polyglycolic acid-chitosan (the mass ratio of polyglycolic acid and chitosan is 70:30) and polyethylene glycol (molecular weight is 800) are dissolved in acetone with 20:2 (mass ratio), The concentration of the formed solution is 10%;

[0037] (4) Coating the casting solution prepared in step (3) on the surface of the hollow braided rope obtained in step (2), then placing it in water for solidific...

Embodiment 3

[0039] (1) The poly(lactic acid-glycolic acid)-chitosan fiber (the mass ratio of poly(lactic acid-glycolic acid) and chitosan is 80:20) fiber with a fineness of 70dtex is twisted for 3 times and then twisted at a rate of 5m / The speed of min is pulled out from the bobbin and guided to the braiding point through the guide wheel of the high-speed braiding machine, and braided into a hollow braided rope;

[0040] (2) the hollow braided rope that step (1) is made is worn on the diameter 1.5mm, and the stainless steel wire that length is 2cm outside, and process braided rope with drum type microwave continuous heater; Microwave output power is 300w, and heating temperature is 120 ℃;

[0041] (3) Dissolve polyglycolic acid-chitosan (the mass ratio of polyglycolic acid and chitosan is 60:40) and polyethylene glycol (molecular weight is 1000) in ethyl acetate with 30:5 (mass ratio) In, the concentration of the solution formed is 30%;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Fiber denier | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com