Graphene oxide reinforced carbon aerogel material, and preparation method and application thereof

A technology of carbon airgel and graphene, which is applied in the direction of carbon preparation/purification, chemical instruments and methods, and other chemical processes, can solve the problems of carbon gel shrinkage, collapse, and RF concentration can not be too high, and achieve excellent Adsorption performance, maintenance of pore structure, effect of increasing hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

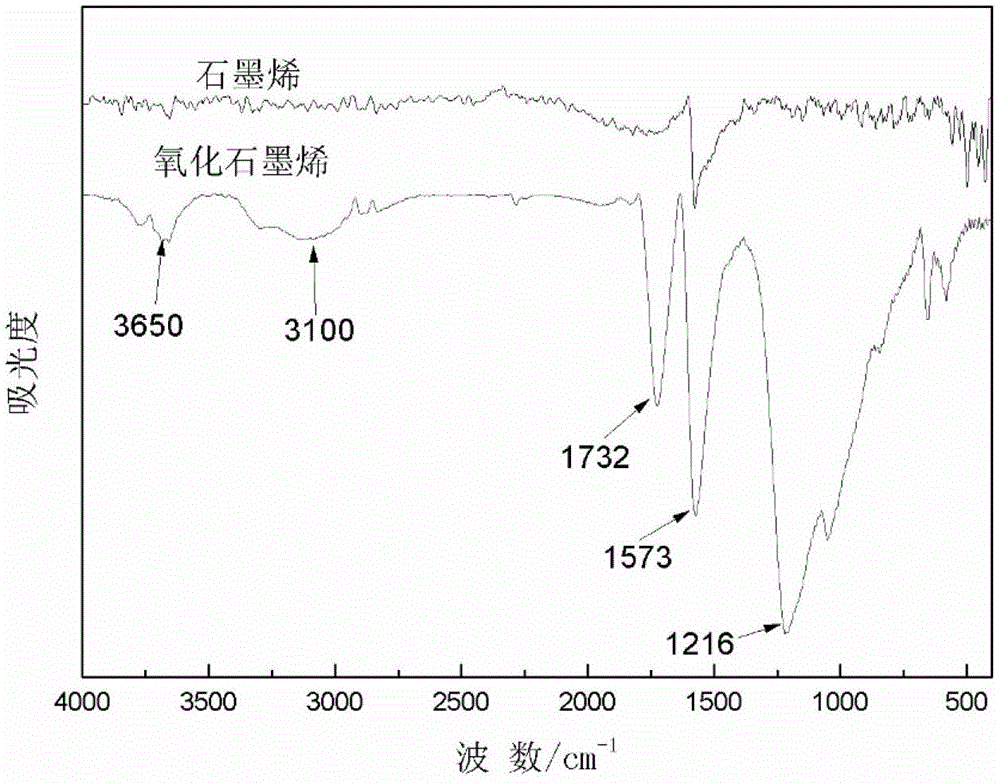

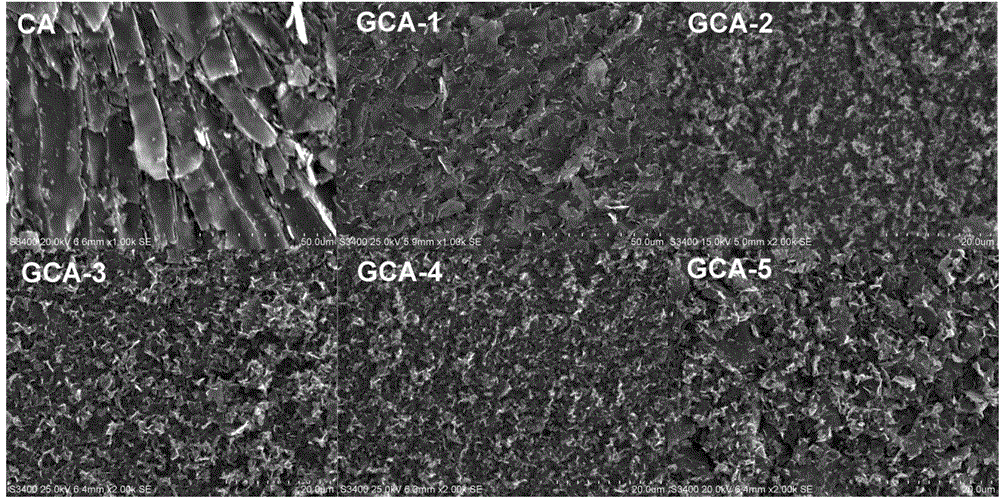

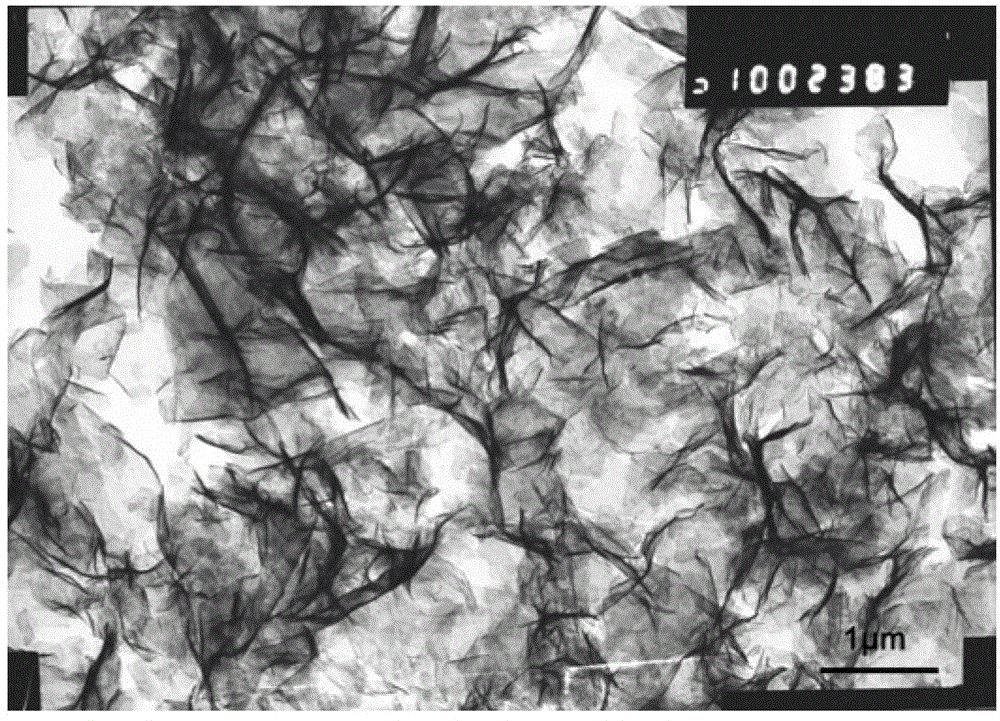

[0026] (1) In parts by weight, add 1 part of powdered natural graphite and 0.5 parts of sodium nitrate into the reactor to cool to 0°C; then slowly add 40 parts of concentrated sulfuric acid into the reactor and stir for 0.5 hours, and keep the reaction system The temperature is 0-5°C; then, add 0.3 parts of potassium permanganate into the reactor and fully stir for 0.5h, while maintaining the temperature of the reaction system at 5-10°C; within 1h, slowly add 3.5 parts of potassium permanganate into the reaction In the container, keep the temperature of the reaction system at 15-20°C, remove the cooling bath, heat the reaction system to 35°C with a water bath, and fully stir for 2 hours to obtain a brown suspension. Slowly add 45 parts of pure water dropwise to the brown suspension, and react at 90°C for 15 minutes. After the reaction, add 3 parts of 30% H to the suspension. 2 o 2 With 20 parts of pure water to obtain a bright yellow graphite oxide dispersion. After the dis...

Embodiment 2

[0032] (1) In parts by weight, add 1 part of powdered natural graphite and 0.3 parts of sodium nitrate into the reactor to cool to 0°C; then slowly add 45 parts of concentrated sulfuric acid into the reactor and stir for 0.7 hours, and keep the reaction system The temperature is 0-5°C; then, add 0.5 parts of potassium permanganate into the reactor and fully stir for 0.3h, while maintaining the temperature of the reaction system at 5-10°C; within 1h, add 4 parts of potassium permanganate slowly In the reactor, keep the temperature of the reaction system at 15-20°C, remove the cooling bath, heat the reaction system to 40°C with a water bath, and fully stir for 2 hours to obtain a brown suspension. Slowly add 50 parts of pure water dropwise into the brown suspension, and react at 95°C for 10 minutes. After the reaction, add 2 parts of 30% H to the suspension. 2 o 2 With 30 parts of pure water to obtain a bright yellow graphite oxide dispersion. After the dispersion liquid is fi...

Embodiment 3

[0037](1) In parts by weight, add 1 part of powdered natural graphite and 0.7 parts of sodium nitrate into the reactor to cool to 0°C; then slowly add 35 parts of concentrated sulfuric acid into the reactor and stir for 0.3 hours, and keep the reaction system constant The temperature is 0-5°C; then, add 0.2 parts of potassium permanganate into the reactor and fully stir for 0.7h, while maintaining the temperature of the reaction system at 5-10°C; within 1h, slowly add 3 parts of potassium permanganate into the reaction In the container, keep the temperature of the reaction system at 15-20°C, remove the cooling bath, heat the reaction system to 30°C with a water bath, and fully stir for 3 hours to obtain a brown suspension. Slowly add 40 parts of pure water dropwise to the brown suspension, and react at 85°C for 20 minutes. After the reaction, add 4 parts of 30%H to the suspension. 2 o 2 With 20 parts of pure water to obtain a bright yellow graphite oxide dispersion. After th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com