Harmonic ingredient of high-power clean diesel oil

A blending and power technology, applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve problems such as unsatisfactory pour point depressing effect and oxidation stability, unsatisfactory mutual compatibility of additive products, uncontrollable mutual influence, etc. , to achieve the effect of shortening the warm-up and start-up time of the cylinder, making the production operation simple and controllable, and improving the fluidity of diesel oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

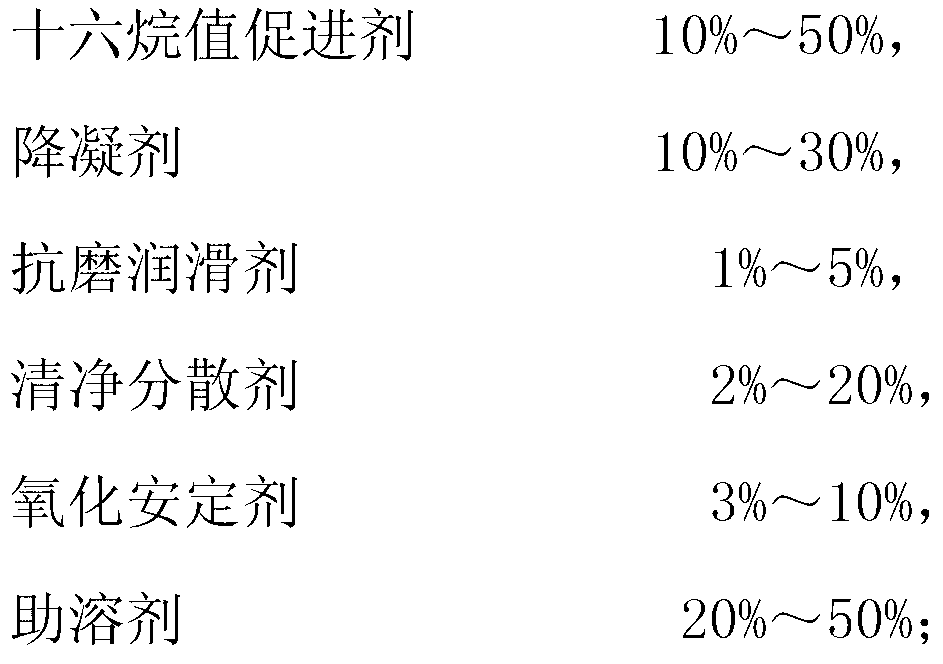

Method used

Image

Examples

Embodiment 1

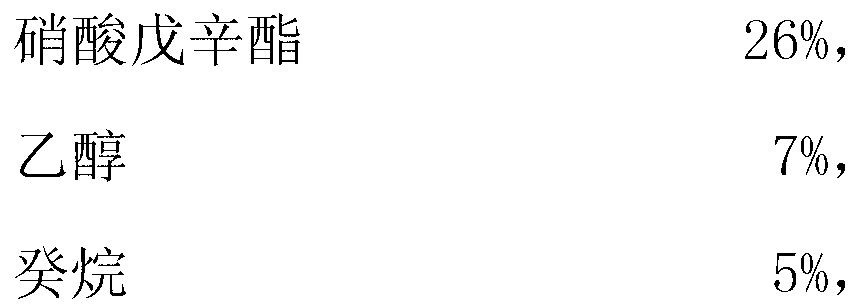

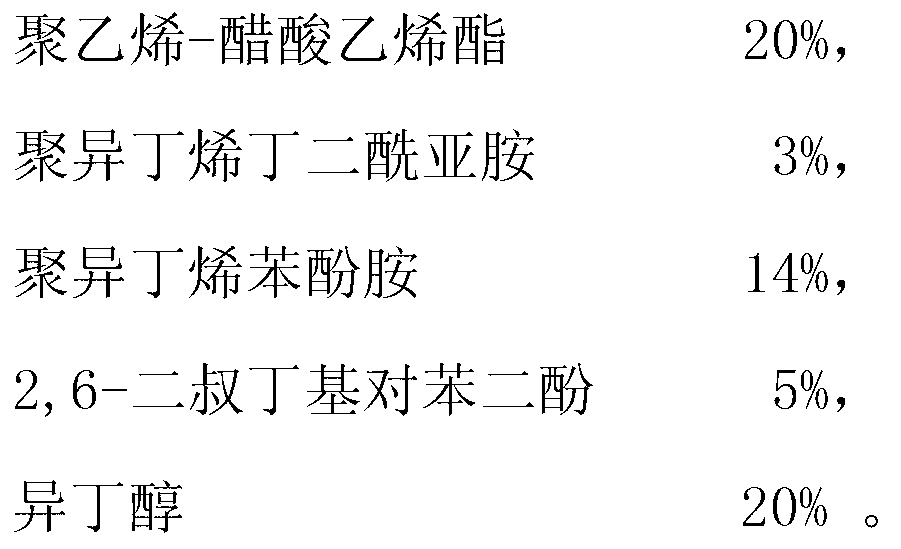

[0047] Get pentyl nitrate 26g, ethanol 7g, decane (C 10 h 22 ) 5g, put into the reaction kettle through a magnetic pump, and then add polyethylene-vinyl acetate 20g, polyisobutylene succinimide 3g, polyisobutylene phenolamine 14g, 2,6 - 5 g of di-tert-butyl hydroquinone and 20 g of isobutanol, heated and kept at 45° C., and circulated and stirred for 4 hours through a reaction kettle or a circulating pump to prepare a finished high-power clean diesel blending component.

[0048] For the refined base oil of China National Petroleum Corporation Changqing Petrochemical Company 0# atmospheric pressure: catalysis: hydrogenated diesel oil = 74:10:16, after adding the blending component whose mass is 0.25% of the refined base oil quality , the cold filter point decreased by 6 degrees, from 5 degrees to -1 degrees, the freezing point decreased by 12 degrees, the cetane number increased by 8 points, the wear diameter decreased from 423 μm to 373 μm, and the oxidation stability was less ...

Embodiment 2

[0050] Get 2-ethylhexyl nitrate 22g, ethanol 2g, dodecane (C 12 h 26 ) 10g, put it into the reaction kettle through a magnetic pump, then add 23g of polyacrylic acid higher alcohol ester, 2g of ethylene glycol linoleate, nonylphenol polyoxyethylene ether amine into the reaction kettle with a gear pump or a self-priming pump 8g, 3g of tert-butyl-p-methyldiphenol, 30g of methylpyrrolidone, heated and kept at 45°C, and stirred by mixing or circulation pump for 3.5 hours to prepare the finished high-power clean diesel blending component.

[0051] For the refined base oil-10# atmospheric pressure of China National Petroleum Corporation Changqing Petrochemical Branch: Catalysis: Hydrogenated diesel = 0:50:50, after adding the blending component whose mass accounts for 0.3% of the refined base oil mass, The cold filter point decreased by 6 degrees from -3 degrees to -9 degrees, the freezing point decreased by 15 degrees, the cetane number increased by 9 points, the wear diameter dec...

Embodiment 3

[0053] Take 28g of pentyl nitrate, 3g of propanol, and 19g of C13-18 mixed alkanes, and add them to the reactor through a magnetic pump, and then use a gear pump or a self-priming pump to add 17g of higher alcohol polyacrylate and linoleic acid to the reactor. 3 g of ethylene glycol ester, 8 g of polyisobutylene phenolamine, 3 g of ascorbic acid, and 20 g of isobutanol were heated and kept at 45°C, and circulated and stirred by a circulation pump for 4 hours to obtain a finished high-power clean diesel blending component.

[0054] For the refining base oil of China National Petroleum Corporation Changqing Petrochemical Branch -10# normal pressure: catalysis: hydrogenated diesel = 0:50:50, the process adjustment was carried out, and the normal cold filter point -3 degrees was raised to 0 degrees , according to the production records, there is 2% more diesel oil. After adding this blending component to the refined base oil at a mass ratio of 0.3%, the cold filter point will be re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation stability | aaaaa | aaaaa |

| oxidation stability | aaaaa | aaaaa |

| oxidation stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com