Anti-static water-based cloth coating mucilage in base cloth in sponges in rubber shoes, and preparation method and application thereof

An anti-static and rubber shoe technology, which is applied in textiles, papermaking, fiber processing, etc., can solve the problems of not having anti-static function, mid-sole cloth scraping glue, bottom cloth adhesion and deformation, etc., to achieve good use effect and good adhesion Good strength, the effect of improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

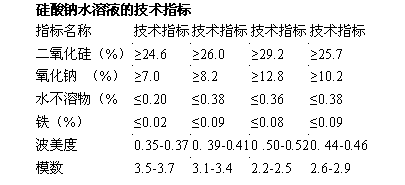

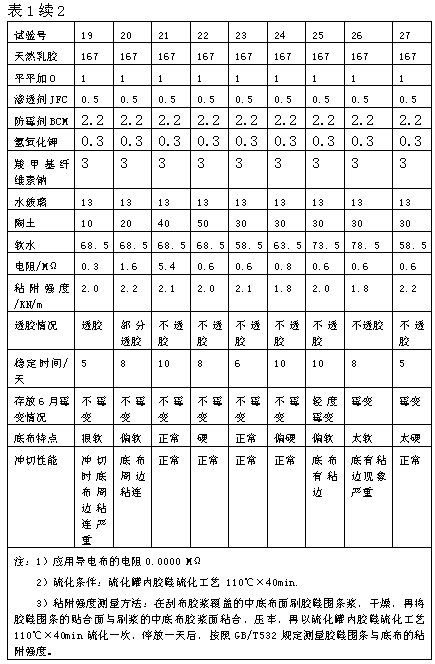

[0029] Embodiment 1 of the present invention: antistatic rubber shoes sponge mid-sole cloth scraping glue, calculated in parts by weight, including 167 parts of natural latex with a solid content of 60%, 30 parts of pottery clay, 1 part of flat plus O, 0.5 part of penetration Agent JFC, 68.5 parts of soft water, 13 parts of water glass with a modulus of 3.2, 2.2 parts of antifungal agent BCM, 0.3 parts of potassium hydroxide and 3 parts of sodium carboxymethylcellulose.

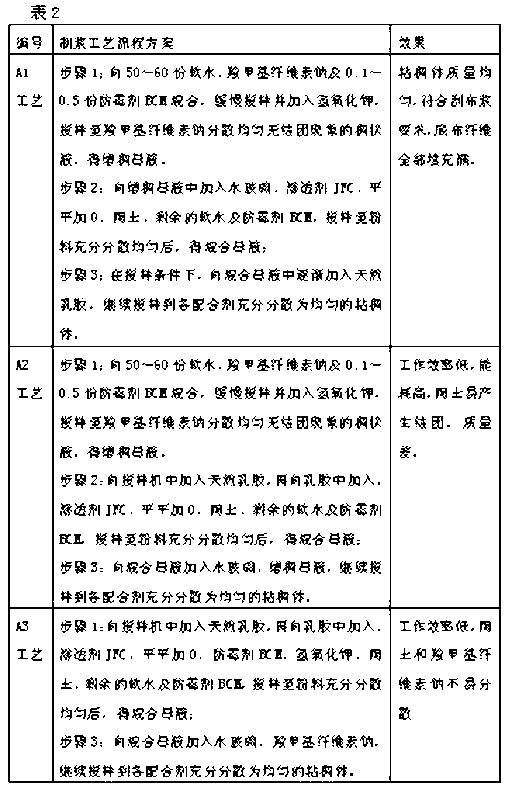

[0030] The preparation method of the scraping glue for the bottom cloth of the anti-static rubber shoes sponge, each component is taken according to the above weight fraction; 1) Prepare the thickening mother liquor: mix 50-60 parts of soft water, sodium carboxymethyl cellulose and 0.1-0.5 parts of anti-static rubber shoes Mix mold agent BCM, stir slowly and add potassium hydroxide, stir until the sodium carboxymethyl cellulose is uniformly dispersed and thick liquid without agglomeration phenomenon, and obtai...

Embodiment 2

[0032] Embodiment 2 of the present invention: Anti-static rubber shoes sponge mid-sole cloth scraping glue, calculated in parts by weight, including 160 parts of natural latex with a solid content of 60%, 35 parts of pottery clay, 0.8 part of flat plus O, 0.6 part of permeation Agent JFC, 65 parts of soft water, 10 parts of water glass with a modulus of 3.1, 2 parts of antifungal agent BCM, 0.35 parts of potassium hydroxide and 4 parts of sodium carboxymethylcellulose.

[0033] The preparation method and application are the same as in Example 1.

Embodiment 3

[0034] Embodiment 3 of the present invention: Anti-static rubber shoes sponge mid-sole cloth scraping glue, calculated in parts by weight, including 170 parts of natural latex with a solid content of 60%, 25 parts of pottery clay, 1.2 parts of Pingping plus O, 0.4 part of permeation Agent JFC, 70 parts of soft water, 15 parts of water glass with a modulus of 3.4, 2.5 parts of antifungal agent BCM, 0.25 parts of potassium hydroxide and 2 parts of sodium carboxymethyl cellulose.

[0035] The preparation method and application are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com