Manufacturing method for machine vision filter

A production method and machine vision technology, applied in the direction of optical filters, etc., can solve the problem of long horizontal image distance, etc., and achieve the effect of satisfying small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

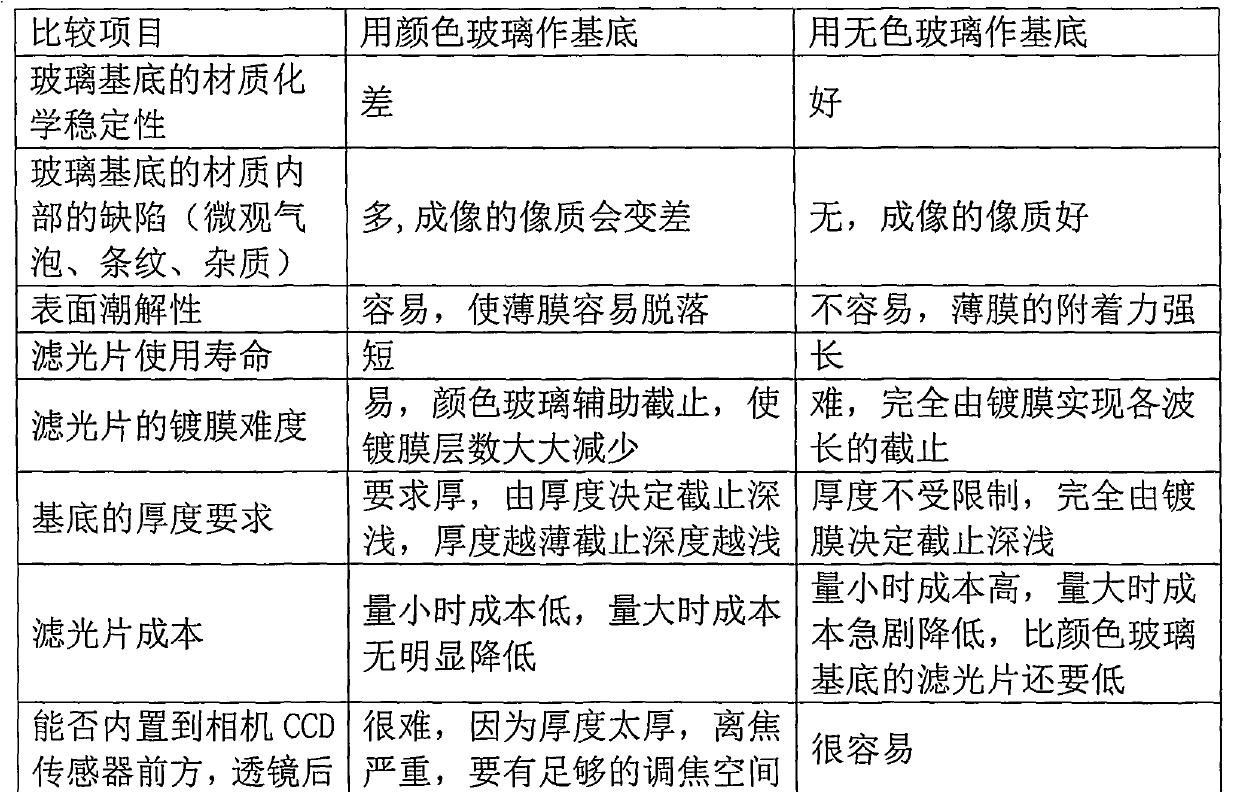

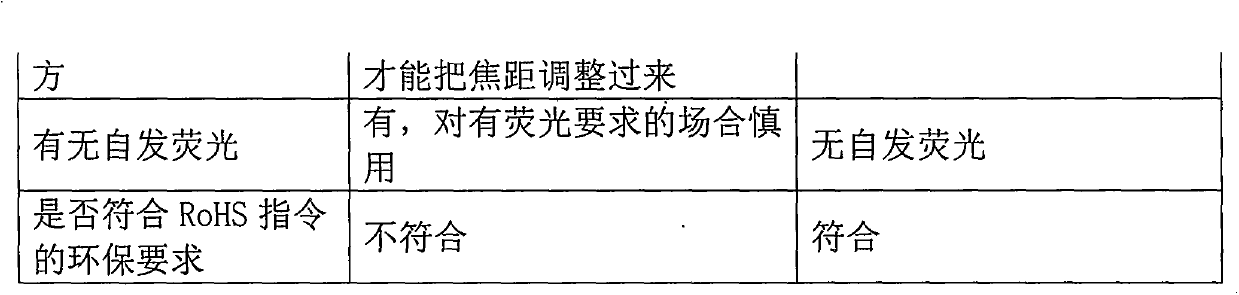

[0026] A method for making a machine vision filter, the steps are as follows:

[0027] A. Cutting: Cut the glass substrate according to the size required by the equipment, and the glass substrate is a colorless glass substrate;

[0028] B. Cleaning: Soak the cut glass substrate in pure water, and use ultrasonic waves for vibration cleaning;

[0029] C. Drying: Dry the cleaned glass substrate by air drying;

[0030] D. Coating the main film: Put the glass substrate into the coating chamber, pump the vacuum of the coating chamber to 0.003Pa, preheat the glass substrate temperature to 320°C, turn on the process gas and the Hall ion source, The main film is plated by ion beam assisted electron beam evaporation coating process;

[0031] E, plating secondary film: after plating the main film, use the same process as in step D to plate the secondary film on the other side of the glass substrate;

[0032] F. Post-processing: Use an inner circle cutting machine to grind the coated g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com