TiO2 nano particle/TiO2 nanotube array and application thereof

A nanotube array and nanoparticle technology, which is applied in chemical/physical processes, surface reaction electrolytic coatings, physical/chemical process catalysts, etc., can solve the problem of low photocatalytic efficiency and electron transmission efficiency, and easy shedding of nanotube arrays, etc. problems, to achieve the effect of improving photocatalytic degradation efficiency, increasing light source irradiation, and improving photocatalytic degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

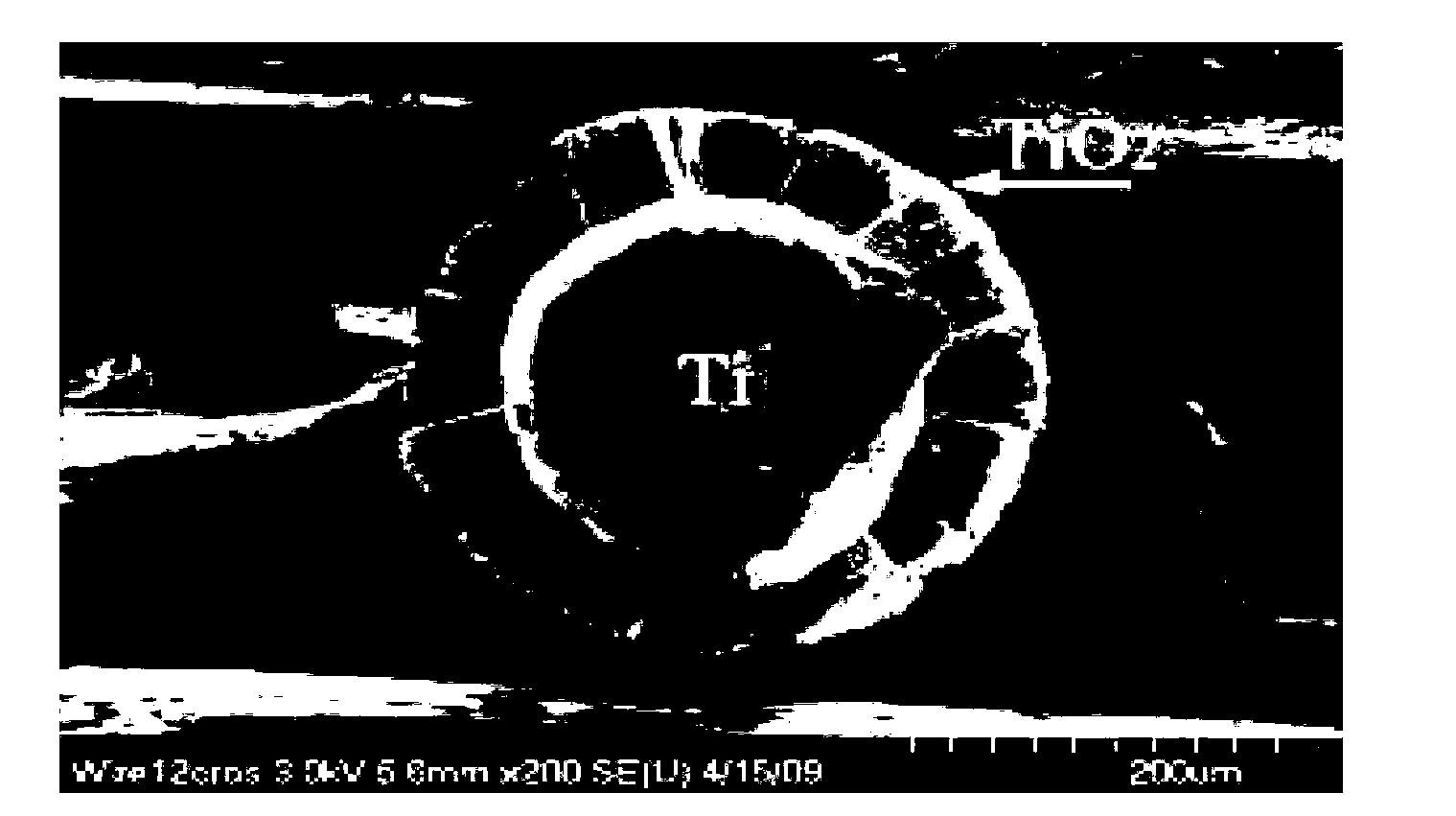

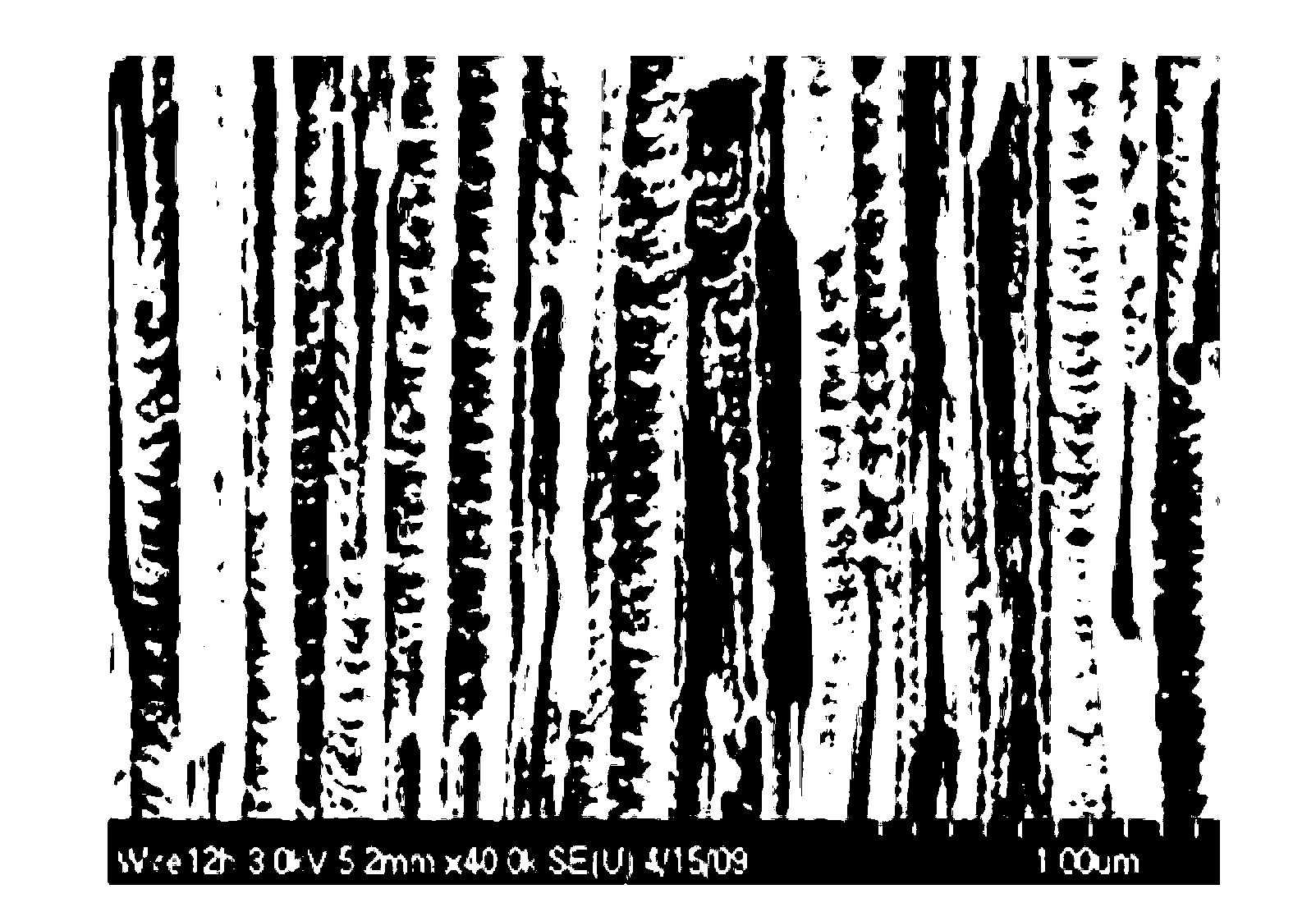

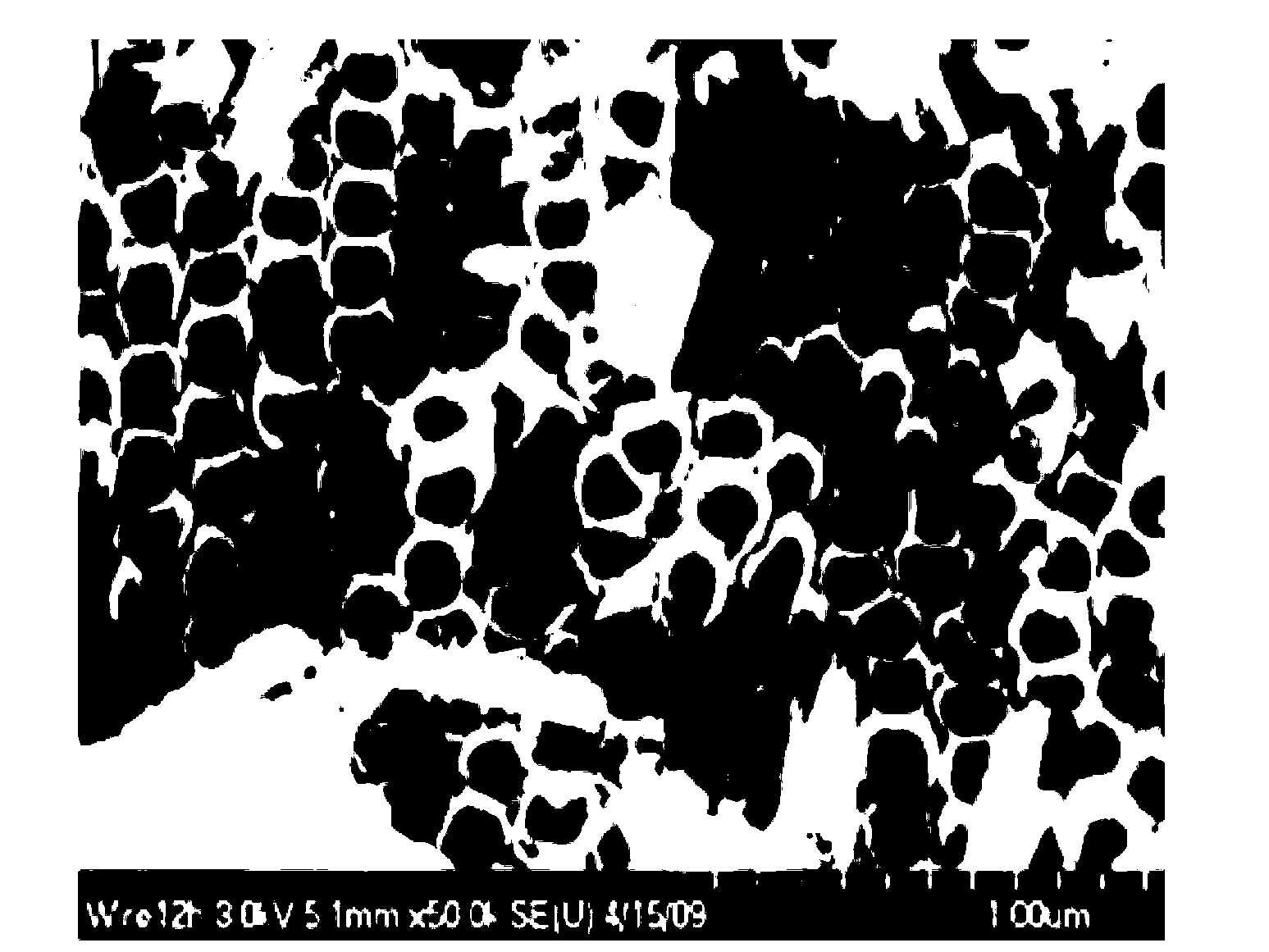

[0042] Example 1TiO 2 Nanoparticles / TiO 2 Fabrication of nanotube arrays

[0043] (1) Pretreatment of titanium wire

[0044] Take a metal titanium wire with a diameter of 2cm and a length of 30cm. After polishing it smoothly, it is ultrasonicated in acetone, isopropanol, methanol, and distilled water for 10 minutes. After natural drying, it is polished in a polishing solution for 1 minute, and then deionized water. Clean and dry naturally in the air, wherein the polishing liquid is made of HF, HNO 3 and H 2 O is composed of 1:3:4 according to the volume ratio;

[0045] (2) TiO 2 Fabrication of nanotube arrays

[0046] Immerse the titanium wire pretreated in step (1) into the electrolyte as the anode, in which the metal titanium wire is immersed in a length of 20cm, and the stainless steel wire is used as the cathode, and the distance between the anode and the cathode is 2cm; the program boost method is adopted Raise to 70V, anodize for 3 hours; rinse the titanium wire w...

Embodiment 2

[0060] Example 2TiO 2 Nanoparticles / TiO 2 Fabrication of nanotube arrays

[0061] (1) Pretreatment of titanium wire

[0062] Take a metal titanium wire with a diameter of 0.02cm and a length of 25cm. After polishing it smoothly, ultrasonically clean it in acetone, isopropanol, methanol, and distilled water for 10 minutes. After natural drying, polish it in a polishing solution for 2 minutes, and then deionize it. Wash with water and dry naturally in the air, wherein the polishing liquid is made of HF, HNO 3 and H 2 O is composed of 1:3:4 according to the volume ratio;

[0063] (2) TiO 2 Fabrication of nanotube arrays

[0064] Immerse the titanium wire pretreated in step (1) into the electrolyte as the anode, in which the metal titanium wire is immersed in a length of 15cm, and the stainless steel wire is used as the cathode, and the distance between the anode and the cathode is 3cm; the programmed voltage increase method is adopted Raise to 90V, anodize for 2 hours; rin...

Embodiment 3

[0074] Example 3TiO 2 Nanoparticles / TiO 2 Fabrication of nanotube arrays

[0075] (1) Pretreatment of titanium wire

[0076] Take a metal titanium wire with a diameter of 3cm and a length of 25cm. After polishing it smoothly, it is ultrasonicated in acetone, isopropanol, methanol, and distilled water for 10 minutes. After natural drying, it is polished in a polishing solution for 3 minutes, and then deionized water. Clean and dry naturally in the air, wherein the polishing liquid is made of HF, HNO 3 and H 2 O is composed of 1:3:4 according to the volume ratio;

[0077] (2) TiO 2 Fabrication of nanotube arrays

[0078] Immerse the titanium wire pretreated in step (1) into the electrolyte as the anode, in which the metal titanium wire is immersed in a length of 20 cm, and the stainless steel wire is used as the cathode, and the distance between the anode and the cathode is 0.7 cm; the voltage is increased by a program After the reaction, rinse the titanium wire with deio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com