Surface modification process for improving luminance and dispersity of porous silicon

A surface modification, porous silicon technology, applied in the direction of silicon, can solve the problems of low luminous efficiency, poor dispersion of porous silicon, poor luminescence stability, etc., to achieve improved luminescence performance and dispersion performance, simple processing technology, strong practicability and The effect of operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

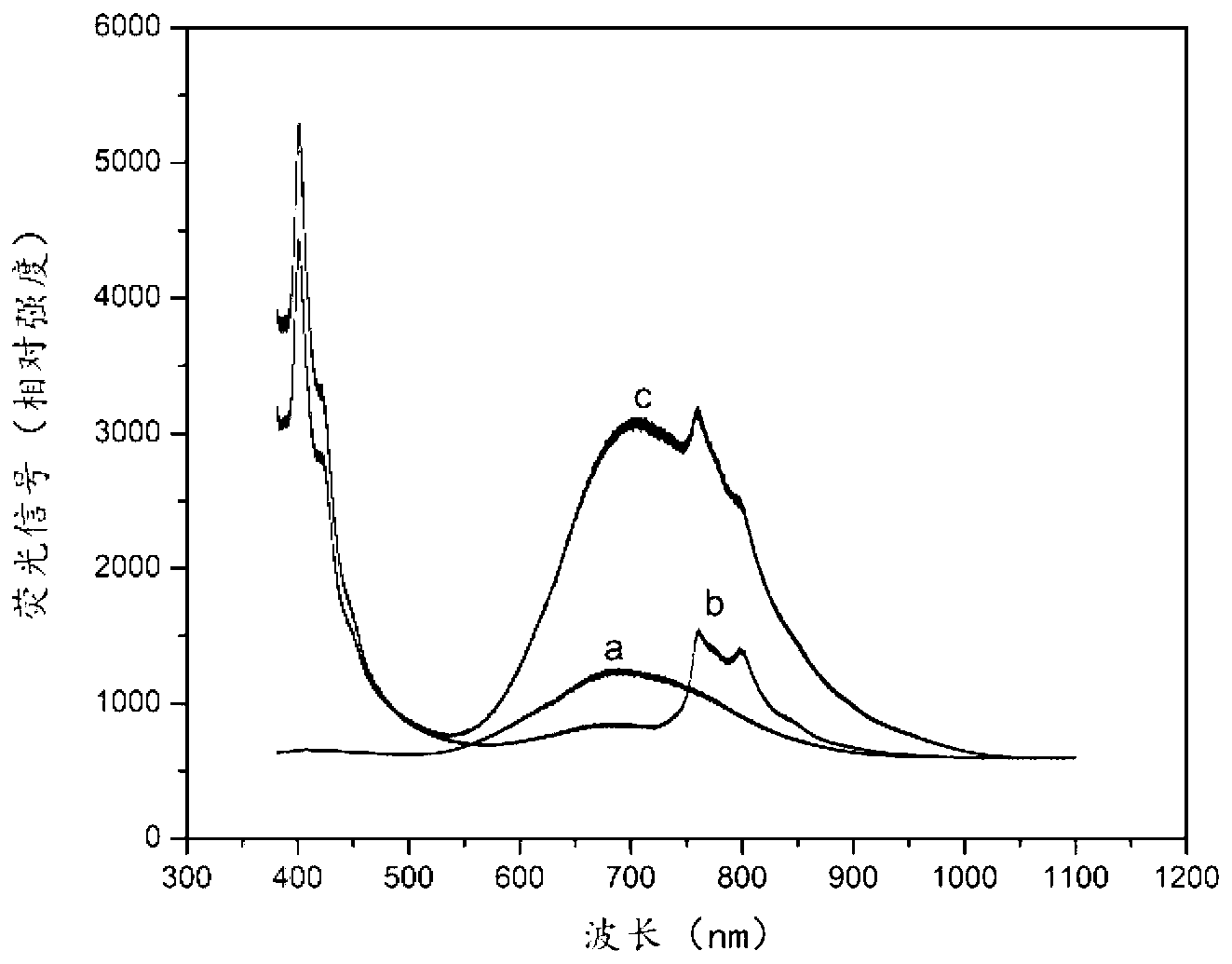

Embodiment 1

[0035] In this example, the prepared porous silicon particles were reacted with dodecene and undecylenic acid in 1,3,5 trimethylbenzene solvent to prepare modified porous silicon particles.

[0036] The preparation method of above-mentioned porous silicon is as follows;

[0037]Step 1: The (100) oriented P-type Czochralski monocrystalline silicon wafer with a resistivity of 10-20Ω.cm used in the preparation of porous silicon is mixed with deionized water, absolute ethanol, acetone, hydrogen peroxide and concentrated sulfuric acid respectively (30% hydrogen peroxide and 98% concentrated sulfuric acid are configured according to the volume ratio of 1:3) for ultrasonic cleaning. Use thermal evaporation equipment to grow aluminum electrodes on the back of the cleaned silicon wafer, and then use diluted hydrofluoric acid solution (5%) to react with the front of the silicon wafer for 5 minutes to remove the oxide layer on the front of the silicon wafer. React the front side of the ...

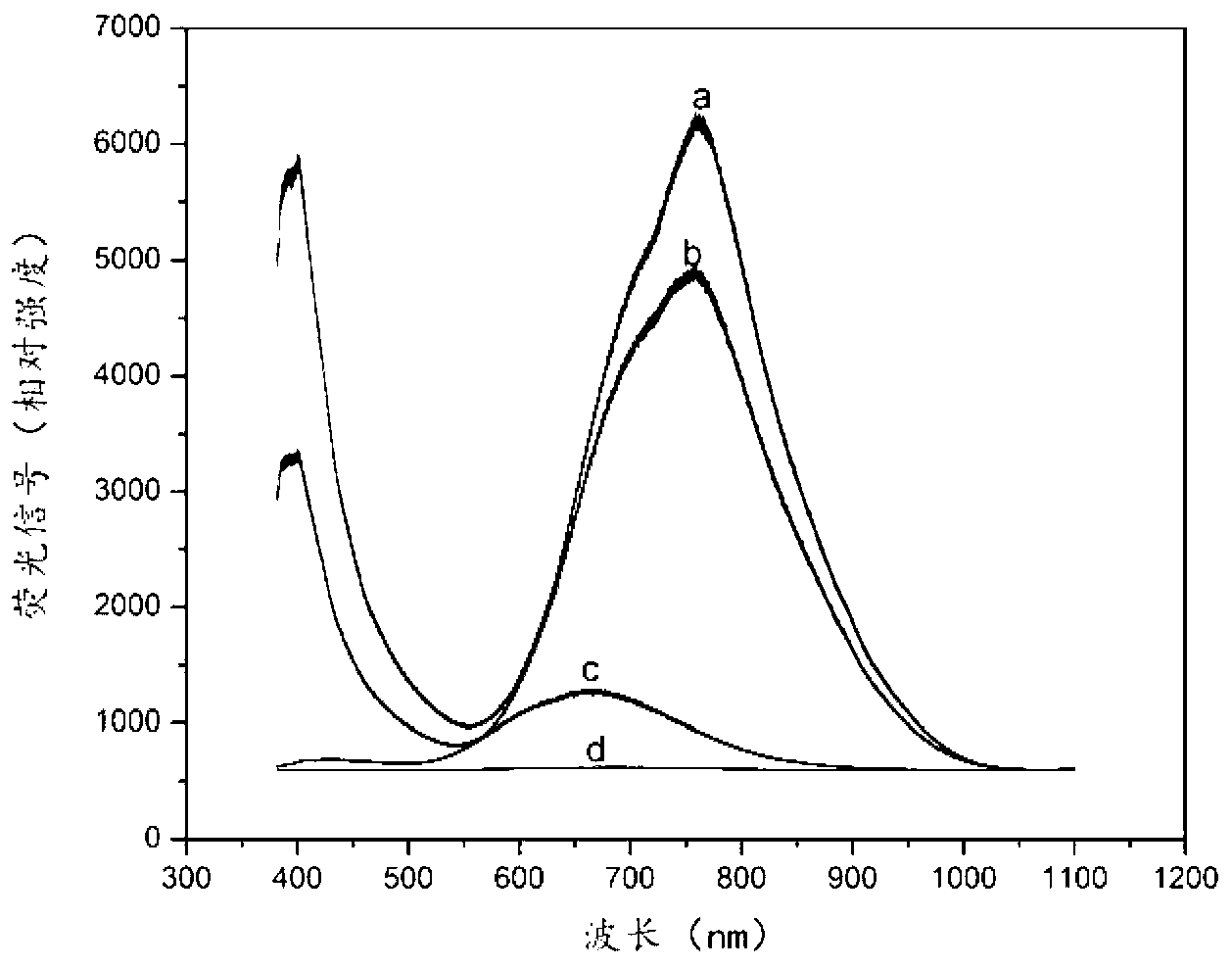

Embodiment 2

[0042] In this example, the prepared porous silicon particles were reacted with octadecene and undecylenic acid in 1,3,5 trimethylbenzene solvent to prepare modified porous silicon particles.

[0043] The preparation method of above-mentioned porous silicon is as follows;

[0044] Step 1: The (100) crystal-oriented N-type Czochralski monocrystalline silicon wafer with a resistivity of 10-20 Ω.cm used in the preparation of porous silicon is mixed with deionized water, absolute ethanol, acetone, hydrogen peroxide and concentrated sulfuric acid respectively. (30% hydrogen peroxide and 98% concentrated sulfuric acid are configured according to the volume ratio of 1:3) for ultrasonic cleaning. Use thermal evaporation equipment to grow aluminum electrodes on the back of the cleaned silicon wafer, and then use diluted hydrofluoric acid solution (20%) to react with the front of the silicon wafer for 10 minutes to remove the oxide layer on the front of the silicon wafer.

[0045] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com