A method for pretreatment of landfill leachate through combination of organic bentonite and TiO2

A technology of landfill leachate and bentonite, which is applied in the direction of adsorption water/sewage treatment, light water/sewage treatment, oxidized water/sewage treatment, etc. It can solve the problem of low pollutant removal efficiency, improve the treatment effect and reduce the odor , the effect of convenient management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

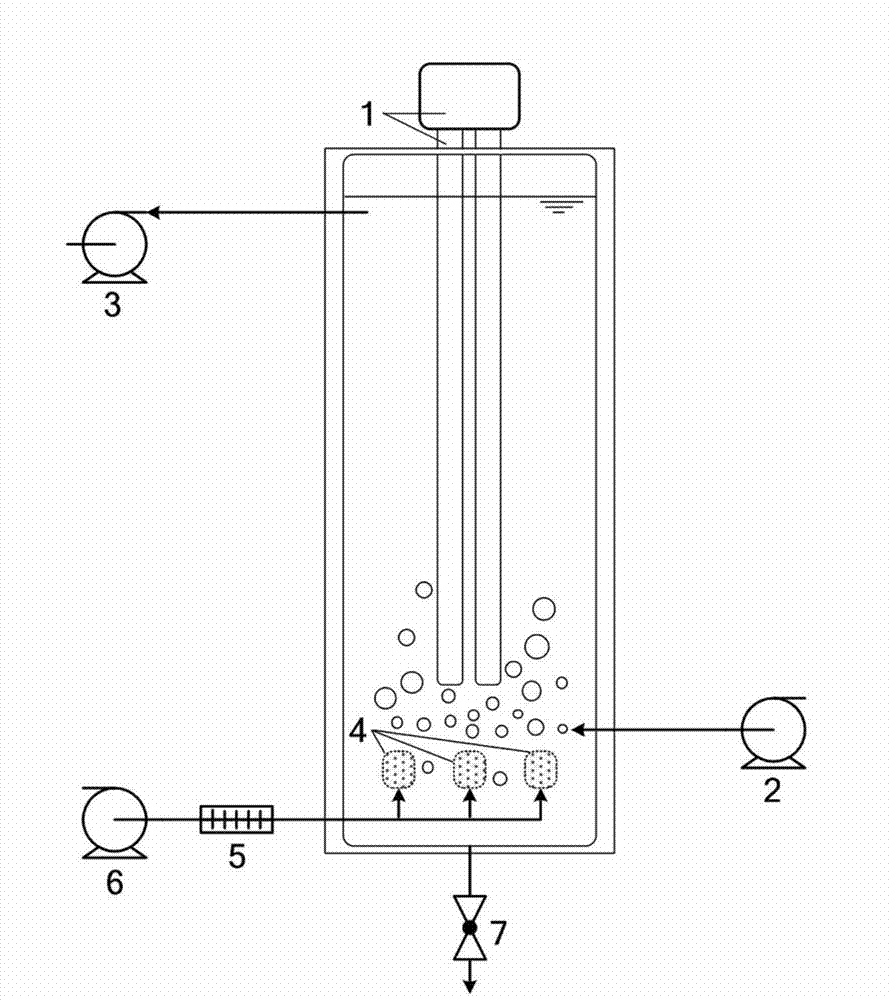

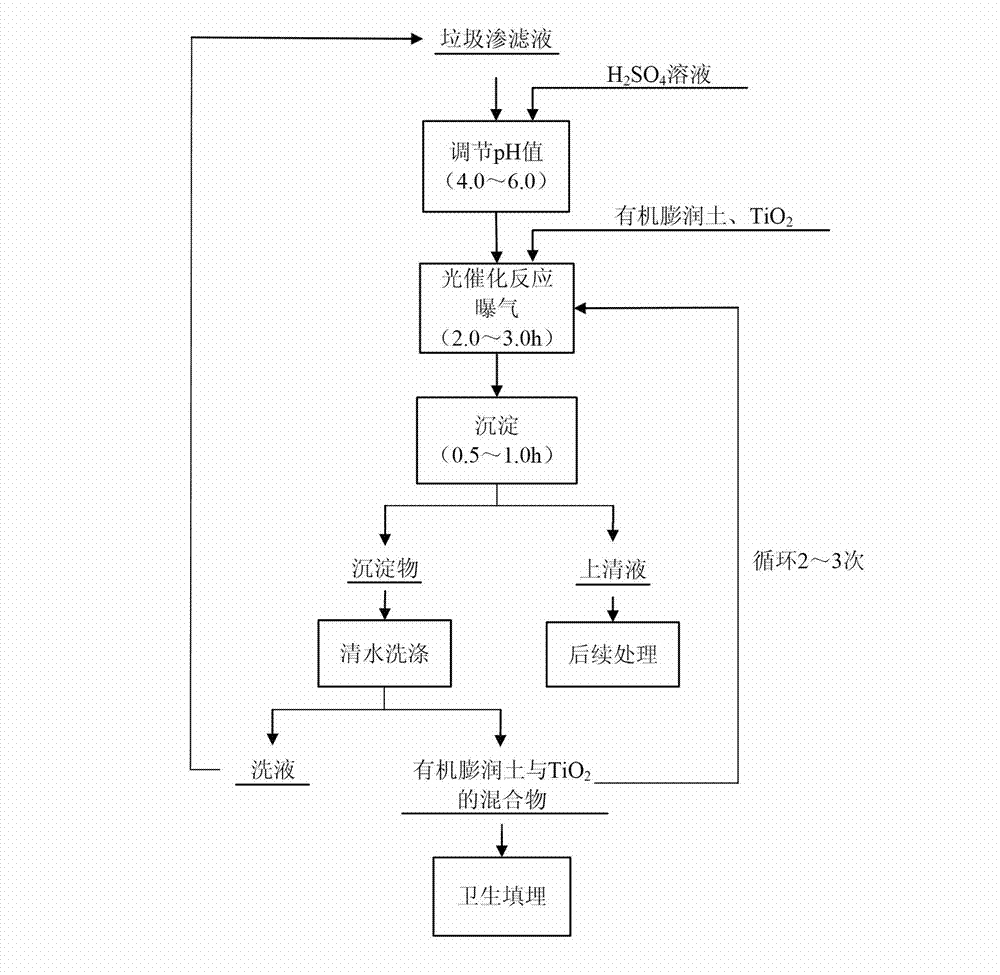

[0032] a kind of like figure 1 , 2 Shown organobentonite and TiO of the present invention 2 A method for joint pretreatment of landfill leachate, comprising the following steps:

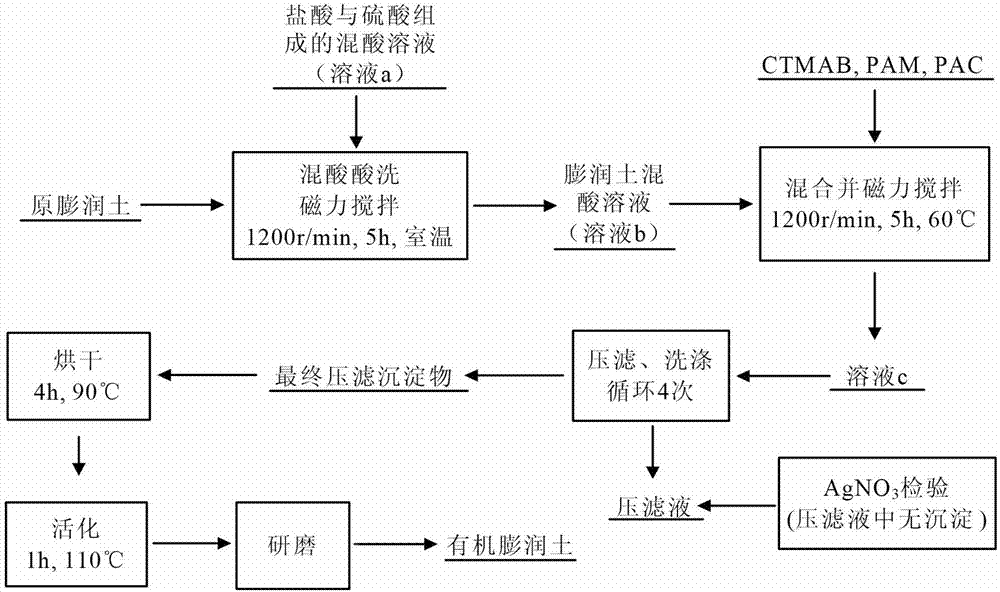

[0033] (1) Preparation of organobentonite (technical route see image 3 )

[0034] (1.1) Slowly add 20ml of hydrochloric acid solution with a mass fraction of 36.5% and 30ml of concentrated sulfuric acid with a mass fraction of 98% into 750ml of distilled water, stir well and cool to room temperature to obtain a mixed acid solution (solution a);

[0035] (1.2) Add 100g of raw bentonite to 800ml of mixed acid solution (mixed acid pickling), and stir at room temperature for 5 hours with a magnetic stirrer at a speed of 1200r / min to obtain bentonite mixed acid solution (solution b);

[0036] (1.3) Add 2.5g cetyltrimethylammonium bromide (CTMAB), 1.0g polyaluminum chloride (PAC) and 0.1g polyacrylamide (PAM) to the bentonite mixed acid solution obtained in step (1.2), Stir with a magnetic stirrer at...

Embodiment 2

[0046] a kind of like figure 1 , 2 The organobentonite and TiO of the present invention shown 2 A method for joint pretreatment of landfill leachate, comprising the following steps:

[0047] (1) Preparation of organobentonite: same as step (1) in Example 1.

[0048] (2) Pretreatment of landfill leachate (see figure 1 and figure 2 )

[0049] (2.1) Add 1L of landfill leachate into the reactor through the water inlet pump 2, and use H with a concentration of 6mol / L 2 SO 4 The solution adjusts the pH value of the landfill leachate to 5.0;

[0050] (2.2) Dosing TiO into the reactor 2 With the organobentonite (CTMAB 2.5) prepared above, add 4g of organobentonite and 3g of TiO per liter of landfill leachate 2 , then start the air pump 6 and turn on the submerged UV lamp 1 with a dominant wavelength of 365nm (photocatalytic reaction), the microporous aeration disc 4 starts aeration, and the aeration volume of the air pump 6 is controlled by the rotameter 5 to 0.4L / min, aft...

Embodiment 3

[0055] a kind of like figure 1 , 2 The organobentonite and TiO of the present invention shown 2 A method for joint pretreatment of landfill leachate, comprising the following steps:

[0056] (1) Preparation of organobentonite: same as step (1) in Example 1.

[0057] (2) Pretreatment of landfill leachate (see figure 1 and figure 2 )

[0058] (2.1) Add 1L of landfill leachate into the reactor through the water inlet pump 2, and use H with a concentration of 6mol / L 2 SO 4 The solution adjusts the pH value of the landfill leachate to 5.0;

[0059] (2.2) Dosing TiO into the reactor 2 With organic bentonite CTMAB 2.5, add 6g of organic bentonite and 3g of TiO per liter of landfill leachate 2 , then start the air pump 6 and turn on the submerged UV lamp 1 with a dominant wavelength of 365nm (photocatalytic reaction), the microporous aeration disc 4 starts aeration, and the aeration volume of the air pump 6 is controlled by the rotameter 5 to 0.4L / min, after the reaction w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com