A system and a method for recycling coal mine drainage and power plant waste water with zero discharge

A treatment system and circulation treatment technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve poor coagulation and clarification effects, low density, No problems such as zero discharge of drained water have been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

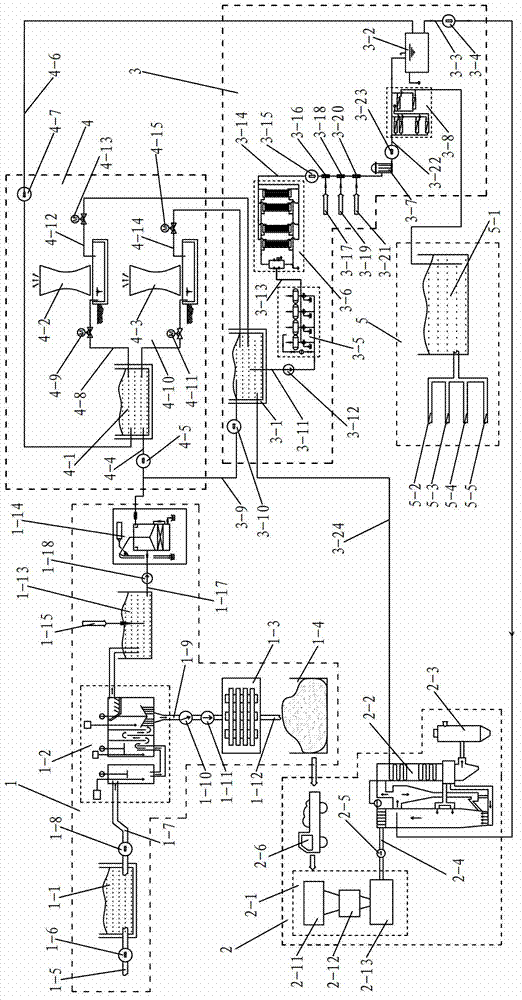

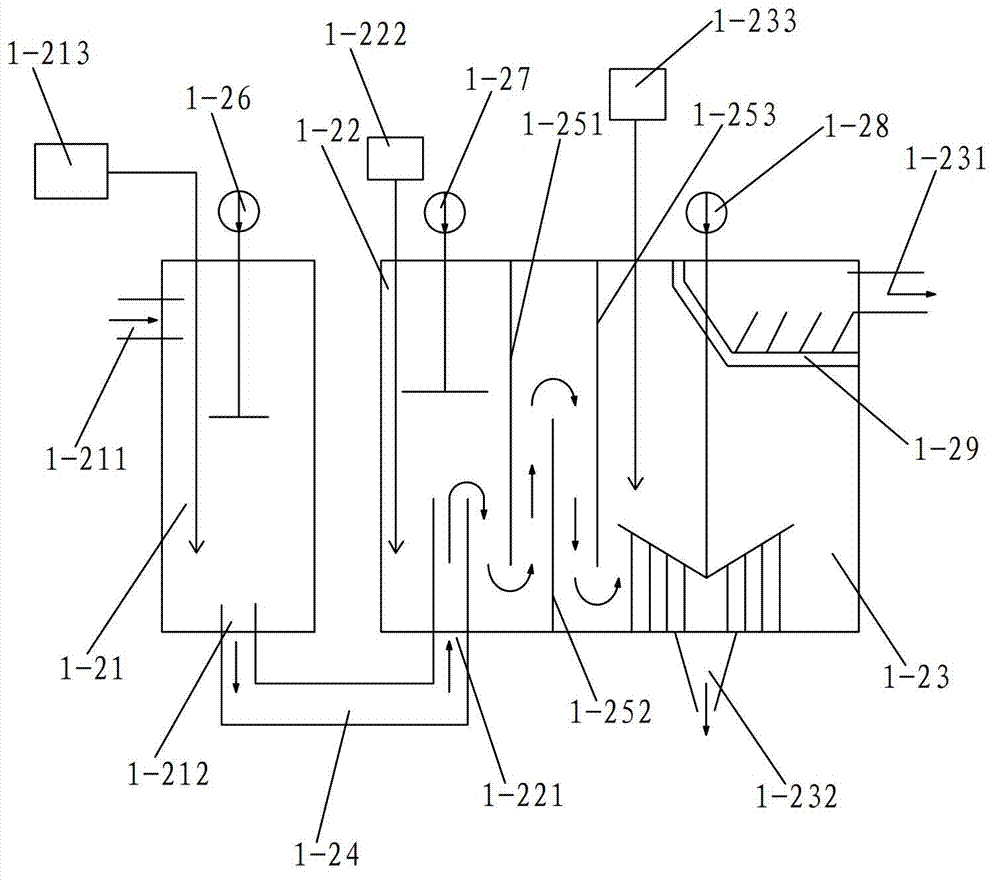

[0105] Such as figure 1 As shown, the zero-discharge system for downhole dewatering water and power plant wastewater recycling treatment and utilization of this embodiment includes a slow decarbonization treatment system for dewatering water 1, a sludge utilization system 2, a boiler sewage recycling system 3, a clean water utilization system 4, and a concentrated Drainage utilization system 5. The slow decarbonization treatment system 1 for draining water includes a draining pond 1-1 for storing underground draining water and a slow decarburizing treatment for slow decarburization of the draining water. The processing device 1-2, and the plate and frame filter press 1-3 for filter press dehydration treatment of the sediment produced by the slow decarburization treatment device 1-2 and the plate and frame filter press 1-3 for storage The slag mud pool 1-4 of the slag mud, the drainage pool 1-1 is connected to the underground drainage through the drainage water collection pipe 1-...

Embodiment 2

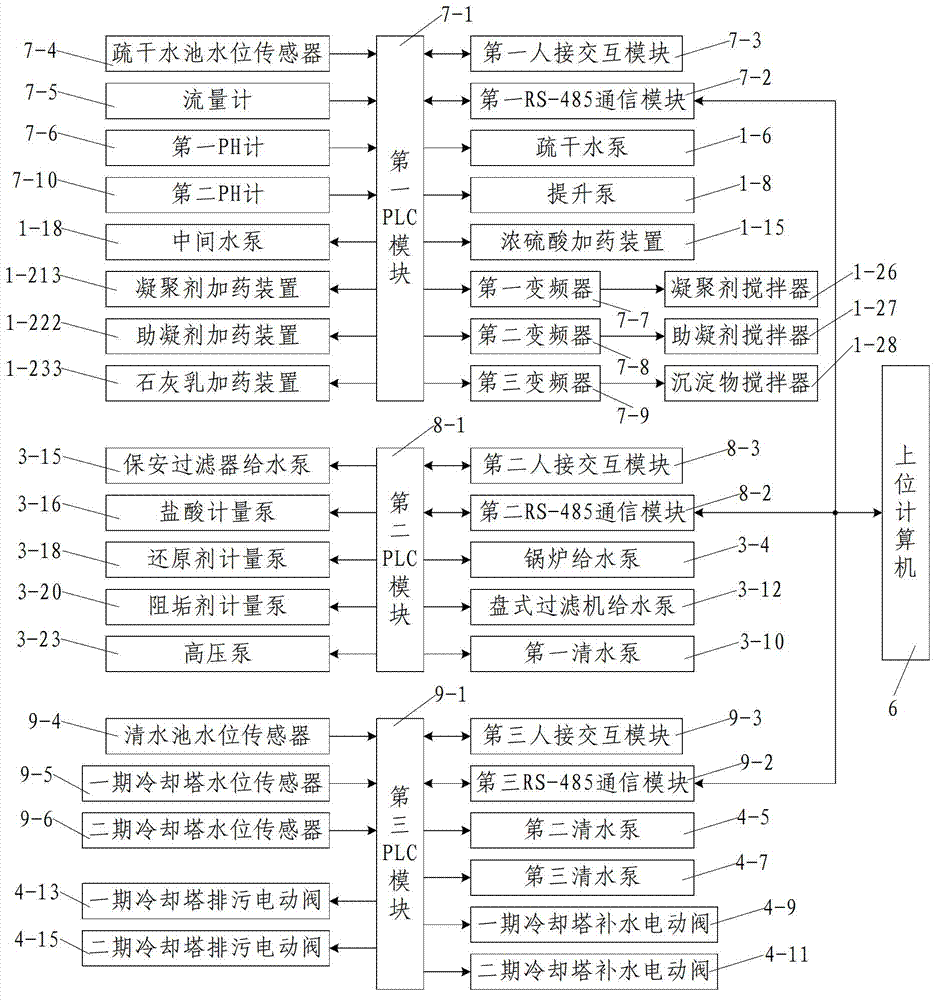

[0132] Combine image 3 The difference between this embodiment and Embodiment 1 is that the zero-discharge system for downhole draining water and power plant wastewater recycling treatment and utilization also includes an upper computer 6, which is used to automatically control the draining water slow decarbonization treatment system 1 The slow decarbonization control system, the boiler blowdown water recycling control system for automatically controlling the boiler blowdown water recycling system 3, and the clean water utilization control system for automatically controlling the clean water utilization system 4, the slow decarbonization control The system includes a first PLC module 7-1, a first RS-485 communication module 7-2 connected to the first PLC module 7-1, and a first person-to-person interaction module 7-3. The drain pool 1-1 A draining pool water level sensor 7-4 for real-time detection of the downhole draining water level in the draining pool 1-1 is provided, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com