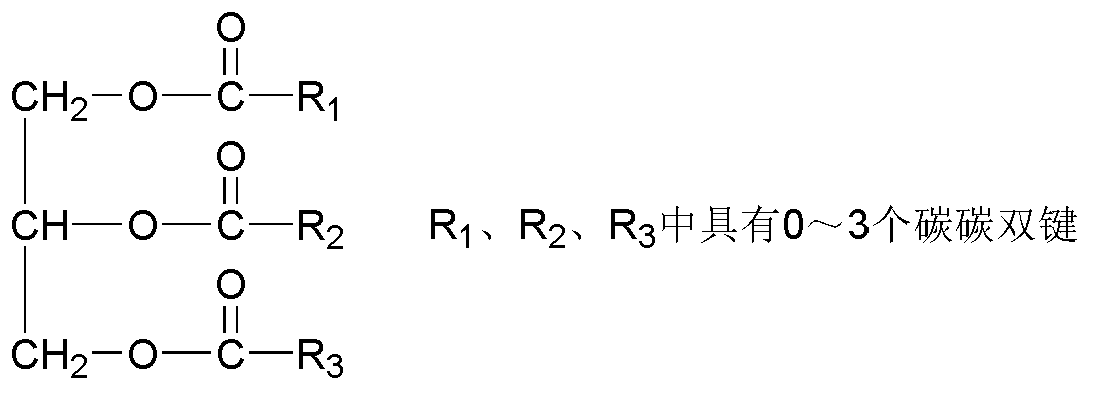

Method for preparing vegetable oil polyalcohol by continuous process

A vegetable oil polyol and continuous method technology, which is applied in the field of continuous method to prepare vegetable oil polyol, can solve the problems of non-continuous production, low product quality, and long reaction time, and achieve the effects of short reaction time, less pollution, and abundant sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

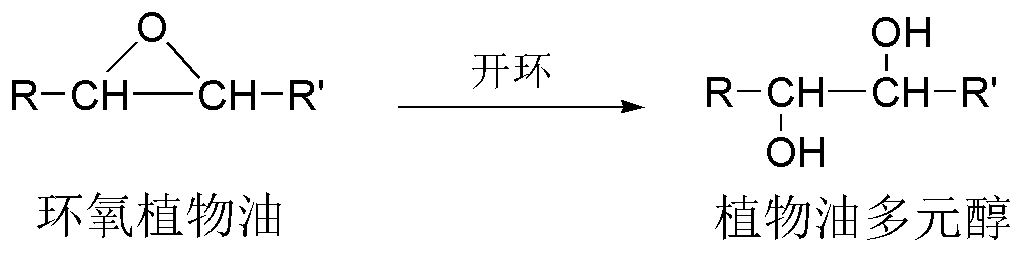

Method used

Image

Examples

Embodiment 1

[0030] Dissolve 200mL epoxy olive oil in 600mL tetrahydrofuran to make component A, and dissolve 13mL sulfuric acid in 240mL water to make component B, and pump them into the microchannel modular reaction device at the same time. The reaction was carried out in , the injection rates of A and B components were 2.8mL / min and 0.9mL / min respectively, and the reaction residence time was kept for 10min. 2 CO 3 The aqueous solution was washed until neutral, and then liquid separation and rotary evaporation were performed to obtain olive oil polyol with a hydroxyl value of 222 mgKOH / g.

Embodiment 2

[0032] Dissolve 200mL epoxy peanut oil in 1000mL tetrahydrofuran to make component A, and dissolve 20mL fluoboric acid in 440mL water to make component B, and pump them into the microchannel modular reaction device at the same time, in the sandwich reactor HC at normal pressure and 80°C The reaction was carried out in , the injection rates of A and B components were 5.3mL / min and 2.1mL / min respectively, and the reaction residence time was kept for 5min. 2 CO 3 The aqueous solution was washed to neutrality, and then the peanut oil polyol was obtained through liquid separation and rotary evaporation, and its hydroxyl value was 265 mgKOH / g.

Embodiment 3

[0034] Dissolve 200mL epoxy rapeseed oil in 700mL tetrahydrofuran to make component A, and dissolve 20mL sulfuric acid in 600mL water to make component B, and pump them into the microchannel modular reaction device at the same time. The reaction was carried out in an alloy microchannel reactor. The injection rates of A and B components were 3.4mL / min and 2.3mL / min respectively, and the reaction residence time was kept at 3.5min. Phase with 5%Na 2 CO 3 The aqueous solution was washed until neutral, and then liquid separation and rotary steaming were performed to obtain rapeseed oil polyol with a hydroxyl value of 222 mgKOH / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com