Method for solvent extraction-column chromatography separation of coal tar, and apparatus thereof

A separation method and coal tar technology, which is applied in the field of coal tar separation, neutral oil and soft pitch, and separation of coal tar to obtain crude phenol, which can solve the problems of low separation efficiency of product components, large amount of phenol-containing wastewater, and many operating procedures and other problems, to achieve the effect of easy expansion of production, less investment, and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below by way of examples.

[0034] 1. Solvent extraction-column chromatography separation coal tar device

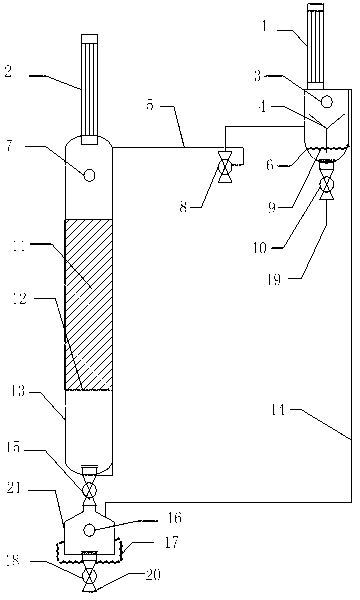

[0035] Such as figure 1 As shown, a solvent extraction-column chromatography separation coal tar device includes a condenser (1), a solvent return pipe (5), an extractor (6), a chromatographic column (13), a steam riser (14), The concentration kettle (21) and the heating device (17), wherein the lower part of the extractor (6) is connected to one end of the solvent return pipe (5), and the other end of the solvent return pipe (5) is connected to the upper end of the chromatography column (13), and the solvent returns The middle part of the tube (5) is provided with a spherical valve A (8), the lower end of the chromatographic column (13) is connected to the top of the concentration kettle (21), and the top side of the concentration kettle (21) is connected to the steam rising pipe (14), and the steam risin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com