Preparation method of tin dioxide doped titanium dioxide based thin film acetone gas sensor

A technology of tin dioxide and titanium dioxide, which is applied in the direction of material resistance, can solve the problems of poor selectivity, high power consumption, and low sensitivity, and achieve the effects of good film quality, low working temperature, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

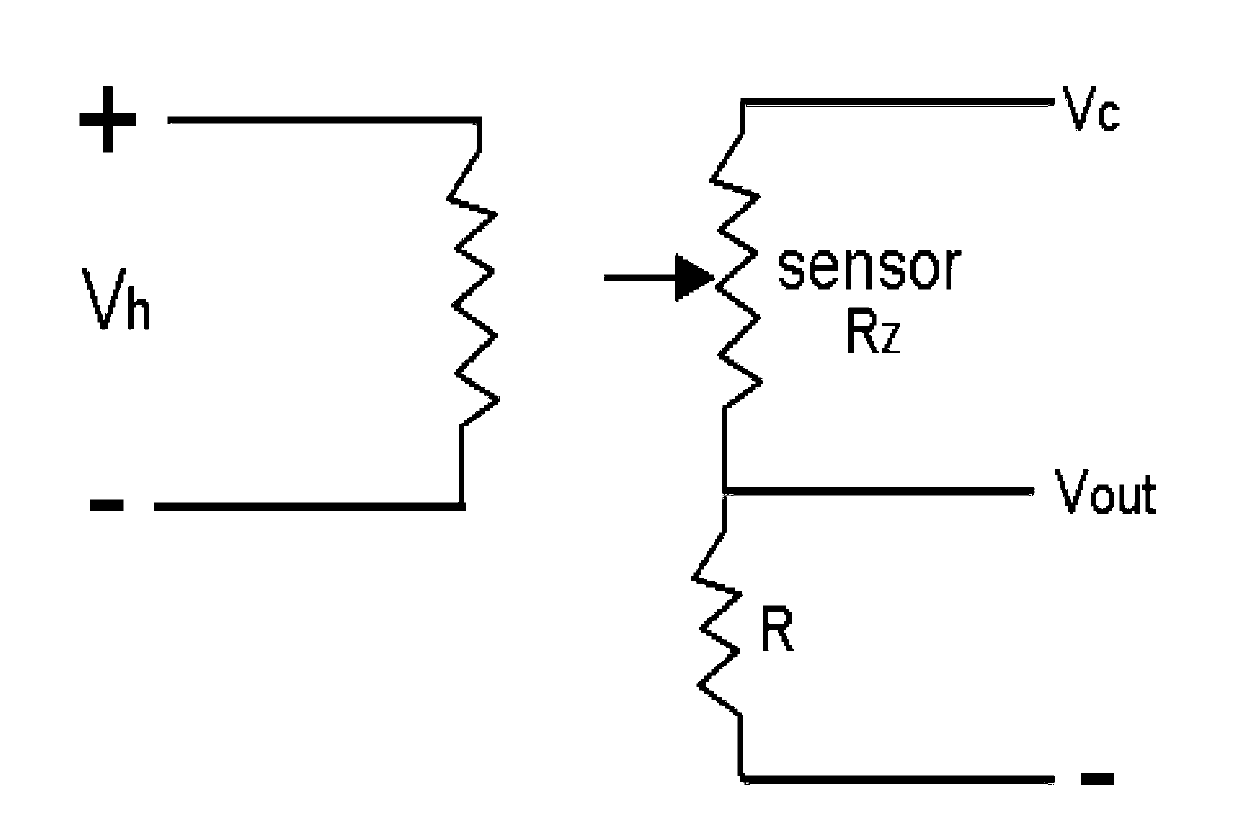

Method used

Image

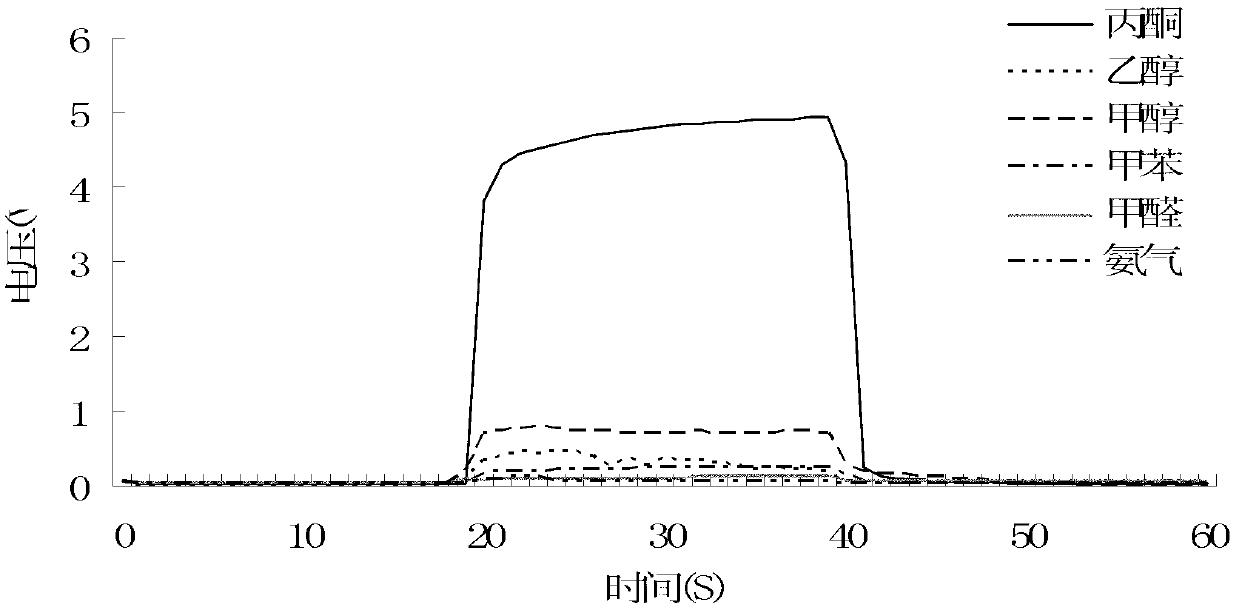

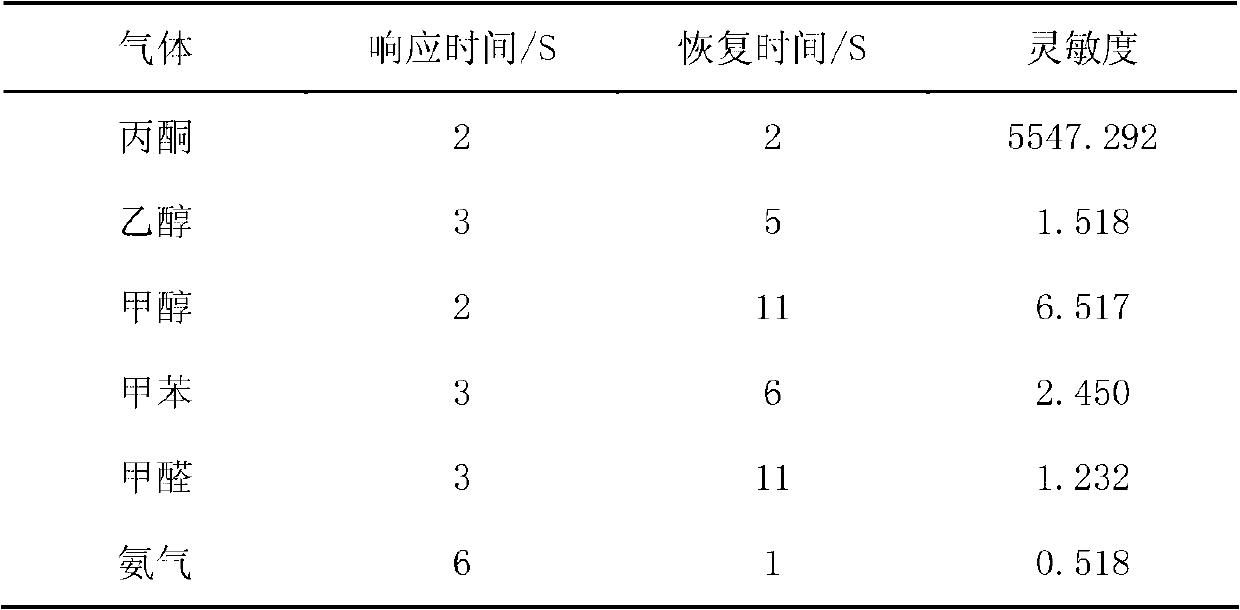

Examples

Embodiment 1

[0022] Sol-gel method in Al 2 o 3 Fabrication of SnO-doped Ceramic Tubes and Silicon Wafers 2 TiO 2 thin film, the doping level is 4%.

[0023] 1 Preparation of doped raw material tin dioxide gel

[0024] With 4.37g of SnCl 4 ·5H 2 O was dissolved in 25mL of deionized water, and two drops of hydrochloric acid were added dropwise for stirring, and ammonia water was added dropwise at the same time, until the pH value of the solution changed to about 6, the dropwise addition of ammonia water was stopped. Stir for another 30 minutes, then leave to age at room temperature for 2 days. After obtaining the stratified sol, remove the supernatant and wash it several times, put it in a drying oven to dry, and obtain a gel; finally, put it in a muffle furnace for annealing at 200°C to obtain SnO 2 Gel powder.

[0025] 2 doped TiO 2 powder preparation

[0026] A. Doped SnO 2 with TiO 2 The molar ratio is 1:25, the calculated SnO 2 The mass of 102.6mg. Take 20mL of absolute et...

Embodiment 2

[0036] Sol-gel method in Al 2 o 3 Fabrication of SnO-doped Ceramic Tubes and Silicon Wafers 2 TiO 2 Thin film, the doping amount is 2%.

[0037] 1 Preparation of doped raw material tin dioxide gel

[0038] With 4.37g of SnCl 4 ·5H 2 O was dissolved in 25mL of deionized water, and two drops of hydrochloric acid were added dropwise for stirring, and ammonia water was added dropwise at the same time, until the pH value of the solution changed to about 6, the dropwise addition of ammonia water was stopped. Stir for another 30 minutes, then leave to age at room temperature for 2 days. After obtaining the stratified sol, remove the supernatant and wash it several times, put it in a drying oven to dry, and obtain a gel; finally, put it in a muffle furnace for annealing at 200°C to obtain SnO 2 Gel powder.

[0039] 2 doped TiO 2 powder preparation

[0040] A. Doped SnO 2 with TiO 2 The molar ratio of SnO is 1:50, the calculated SnO 2 The mass of 51.3mg. Take 20mL of abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com