Alginate-chitosan microcapsule modified via PEG grafting and preparation and application thereof

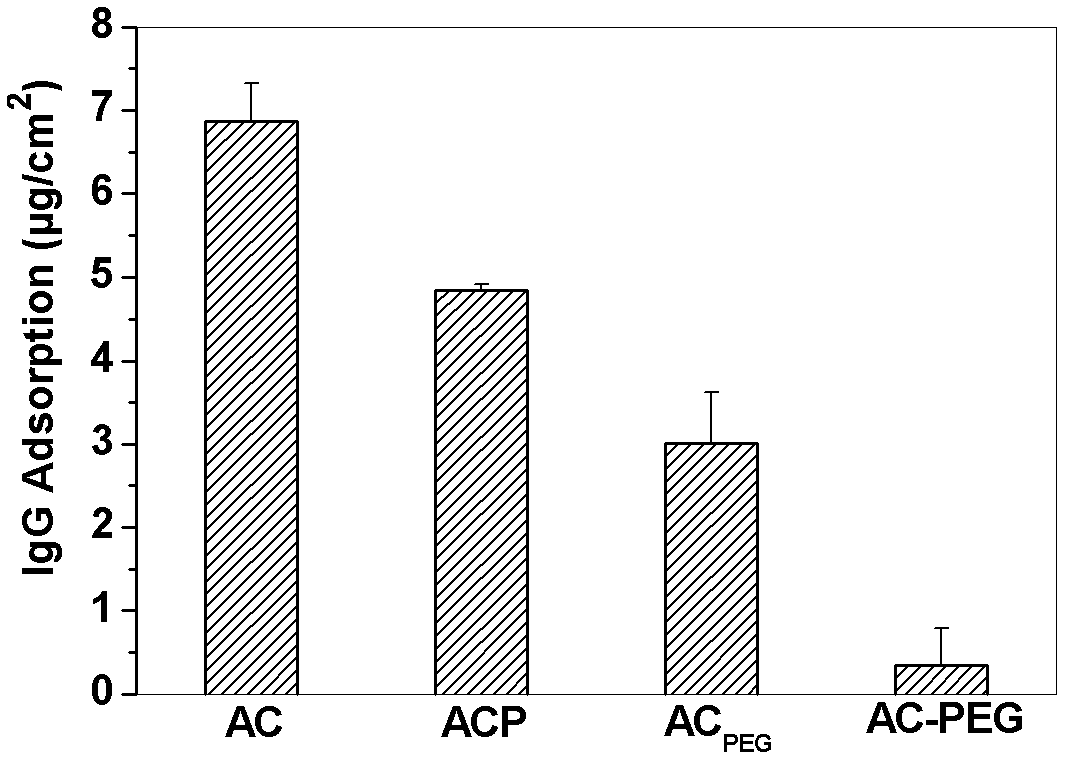

A technology of chitosan microcapsules and alginate, which is applied in the direction of microcapsule preparation, microsphere preparation, immobilization on/in organic carriers, etc., and can solve the problems of large surface roughness and surface charge, protein adsorption, etc. , to achieve the effects of improving stability, increasing graft density, and excellent biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

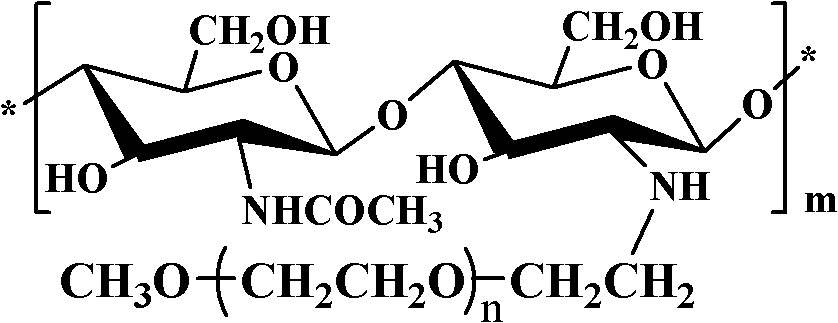

Method used

Image

Examples

Embodiment 1

[0037] 1) Terminal aldylation of PEG: The molecular weight of PEG is 500 Da. The terminal hydroxyl group of PEG is oxidized into aldehyde group by oxidation method to prepare PEG-CHO. The PEG-CHO is dissolved in normal saline at a concentration of 10 g / L.

[0038] 2) Preparation of chitosan solution: chitosan molecular weight 20kDa, deacetylation degree 90%, dissolved in sodium acetate / acetic acid buffer solution with pH 6.5, concentration 10g / L.

[0039] 3) Preparation of AC microcapsules: immerse calcium alginate gel beads prepared by high-voltage electrostatic method into chitosan solution, the volume ratio of microspheres and chitosan solution is 1:40, react for 20 minutes, wash with normal saline, and prepare AC microcapsules.

[0040] 4) Immerse the AC microcapsules in the PEG-CHO solution, drop the reducing agent sodium triacetoxyborohydride solution, the concentration of sodium triacetoxyborohydride is 0.1g / L, the microspheres, PEG-CHO and triacetoxy The volume ratio ...

Embodiment 2

[0057] 1) Terminal aldylation of PEG: The molecular weight of PEG is 2 kDa, and the hydroxyl group at the end of PEG is oxidized to form an aldehyde group by an oxidation method to prepare PEG-CHO. The PEG-CHO is dissolved in normal saline at a concentration of 5 g / L.

[0058] 2) Preparation of chitosan solution: chitosan molecular weight 60kDa, deacetylation degree 90%, dissolved in sodium acetate / acetic acid buffer solution of pH 6.5, concentration 5g / L, the solution is represented by C.

[0059] 3) Immerse the calcium alginate gel microspheres embedded with porcine islet cells in the chitosan solution prepared in step 2), the volume ratio of the microspheres to the chitosan solution is 1:10, react for 20 minutes, and wash with normal saline , prepared into AC microcapsules.

[0060] 4) Immerse the AC microcapsules prepared in step 3) into the PEG-CHO solution prepared in step 1), add dropwise the reducing agent sodium cyanoborohydride solution, the concentration of sodium c...

Embodiment 3

[0064] 1) Terminal aldylation of PEG: The molecular weight of PEG is 10kDa, and the hydroxyl group at the end of PEG is oxidized into aldehyde group by oxidation method to prepare PEG-CHO, which is dissolved in normal saline at a concentration of 5g / L.

[0065] 2) Preparation of chitosan solution: chitosan molecular weight 100kDa, deacetylation degree 90%, dissolved in sodium acetate / acetic acid buffer solution of pH 6.5, concentration 5g / L, solution is represented by C.

[0066] 3) Immerse the calcium alginate gel microspheres embedded with pig liver cells in the chitosan solution prepared in step 2), the volume ratio of the microspheres to the chitosan solution is 1:10, react for 10 minutes, and wash with normal saline , prepared into AC microcapsules.

[0067] 4) Immerse the AC microcapsules prepared in step 3) into a 1.5 g / L sodium alginate solution, react for 10 minutes, wash with physiological saline, and prepare ACA microcapsules.

[0068] 5) Repeat step 3) to prepare ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com