Alcohol-based non-zirconium composite refractory aggregate spray paint for wet cast steel and preparation method thereof

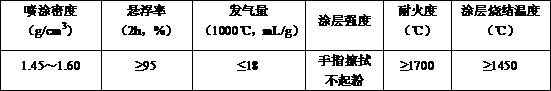

A refractory aggregate and non-zirconium technology, which is applied in the field of alcohol-based non-zirconium composite refractory aggregate spraying coating and preparation for wet cast steel, can solve the problem of inability to form a refractory isolation layer, poor anti-sticking effect, and sticking sand or sand inclusion defects and other problems, to achieve excellent suspension stability, less sand sticking defects, and the effect of coating without peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Step 1, additive prefabrication:

[0050] 1.1 Mix 2.0 parts by weight of magnesium aluminum silicate superfine powder with 4 parts by weight of water, add 15 parts by weight of grain ethanol and 3 parts by weight of silica sol, put it into a colloid mill and grind for 8 minutes to make paste A;

[0051] 1.2 Dissolve 0.3 parts by weight of polyvinyl butyral in 30 parts by weight of methanol to obtain a transparent solution A, mix the transparent solution A with the paste A evenly, put it into a colloid mill and grind for 8 minutes to make a paste B;

[0052] 1.3 Dissolve 2 parts by weight of modified rosin ester in 6 parts by weight of methanol to obtain a transparent solution B, mix the transparent solution B with 1 part by weight of calcium-based bentonite, put it into a colloid mill and grind for 8 minutes to make a paste C ;

[0053] 1.4 Add paste B, paste C and 5 parts by weight of methanol into a high-speed mixer and stir for 20 minutes to make paste D. The speed...

Embodiment 2

[0058] Step 1, additive prefabrication:

[0059] 1.1 Mix 2.5 parts by weight of magnesium aluminum silicate superfine powder with 5 parts by weight of water, add 20 parts by weight of grain ethanol and 5 parts by weight of silica sol, put it into a colloid mill and grind for 12 minutes to make paste A;

[0060] 1.2 Dissolve 0.5 parts by weight of polyvinyl butyral in 35 parts by weight of methanol to obtain a transparent solution A, mix the transparent solution A with the paste A evenly, put it into a colloid mill and grind for 12 minutes to make a paste B;

[0061] 1.3 Dissolve 3 parts by weight of modified rosin ester in 9 parts by weight of methanol to obtain a transparent solution B, stir the transparent solution B and 1.5 parts by weight of calcium-based bentonite evenly, put it into a colloid mill and grind for 12 minutes to make paste C ;

[0062] 1.4 Add paste B, paste C and 10 parts by weight of methanol into a high-speed mixer and stir for 30 minutes to make paste D...

Embodiment 3

[0067] Step 1, additive prefabrication:

[0068] 1.1 Mix 2.3 parts by weight of magnesium aluminum silicate superfine powder with 4.5 parts by weight of water, add 17 parts by weight of grain ethanol and 4 parts by weight of silica sol, put it into a colloid mill and grind for 10 minutes to make paste A;

[0069] 1.2 Dissolve 0.4 parts by weight of polyvinyl butyral in 32 parts by weight of methanol to obtain a transparent solution A, mix the transparent solution A with the paste A evenly, put it into a colloid mill and grind for 10 minutes to make a paste B;

[0070] 1.3 Dissolve 2.5 parts by weight of modified rosin ester in 7.5 parts by weight of methanol to obtain a transparent solution B, stir the transparent solution B and 1.2 parts by weight of calcium-based bentonite evenly, put it into a colloid mill and grind for 10 minutes to make paste C ;

[0071] 1.4 Add paste B, paste C and 8 parts by weight of methanol into a high-speed mixer and stir for 25 minutes to make pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com