Method for producing high-nutrient monoammonium phosphate by dual-tube reverse process

A monoammonium phosphate, double-tube reverse technology, applied in the field of ammonium phosphate, to achieve the effect of enhancing adaptability, expanding product types, and achieving multi-functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

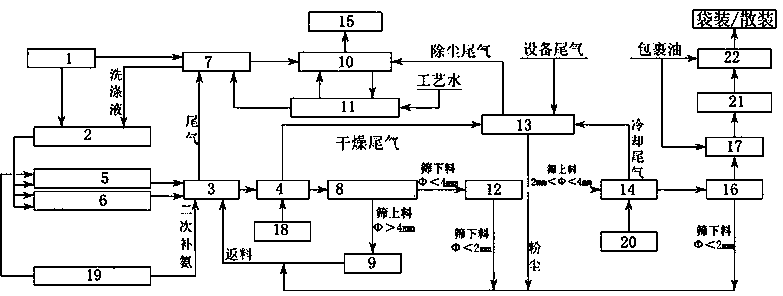

Method used

Image

Examples

Embodiment Construction

[0039] Wengfu Phosphate Fertilizer Factory adopts the present invention on a 600kt / a diammonium phosphate device to produce high-nutrient monoammonium phosphate by adopting a double-pipe reactive process, with stable production process parameters and good equipment operation. The control system is Yokogawa DCS (distributed control system) CENTUM CS control platform.

[0040] (1) Production preparation

[0041] Wengfu (Group) Co., Ltd. Wengfu Phosphate Fertilizer Plant 20kt / a wet-process phosphoric acid plant phosphoric acid is concentrated by forced circulation vacuum evaporation and concentrated phosphoric acid enters concentrated phosphoric acid clarification tank 1 for sedimentation and clarification to remove suspended solids and reduce concentrated phosphoric acid Contains solids.

[0042] (2) Production transfer process

[0043] Reduce the amount of material returned to the system to about 380t. During the conversion process, single-pipe reverse control is adopted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com