High-efficiency electrocoagulation device for sewage treatment

A technology of sewage treatment and flocculation device, which is applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Overcome and other problems to achieve the effect of reducing COD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

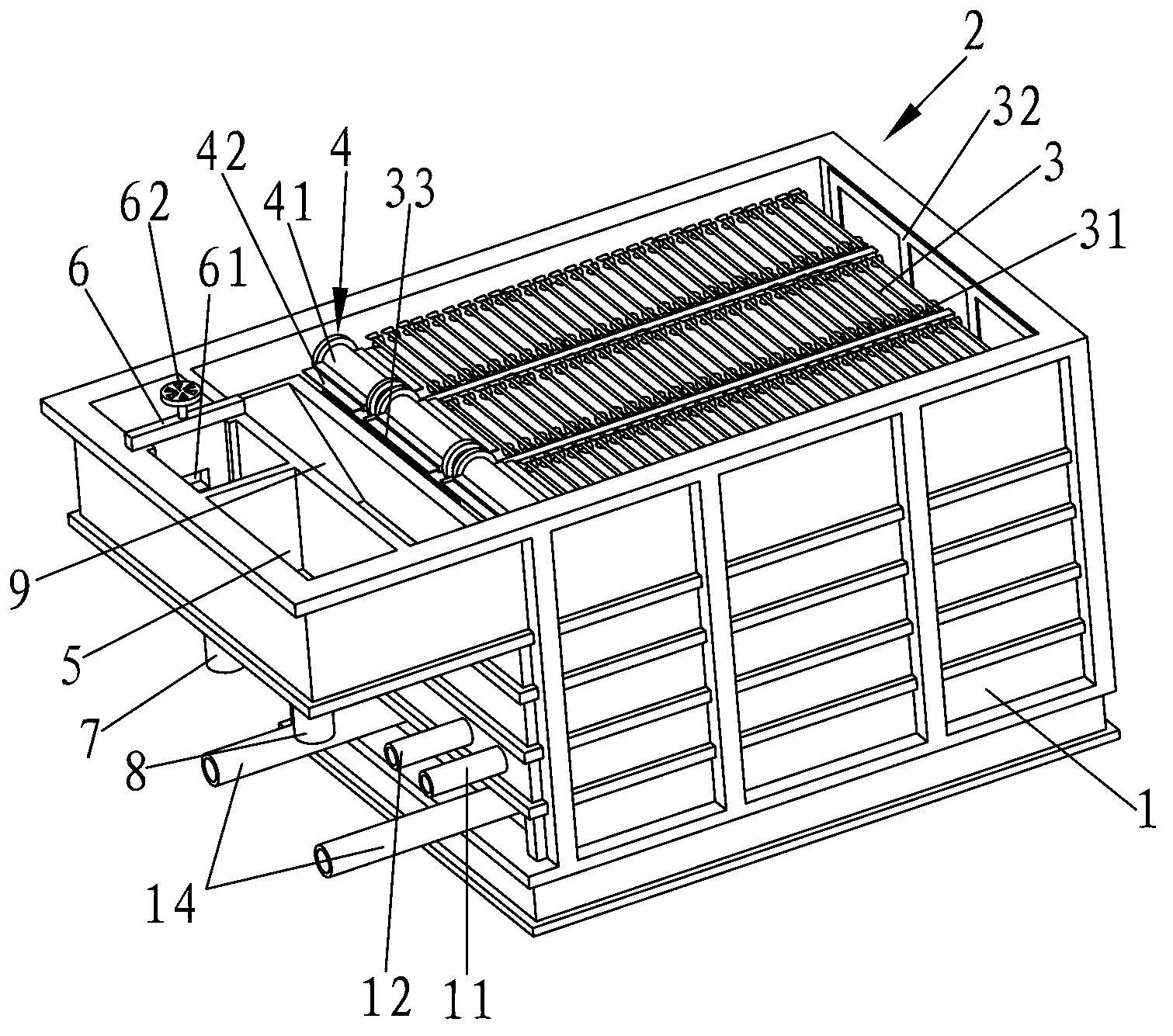

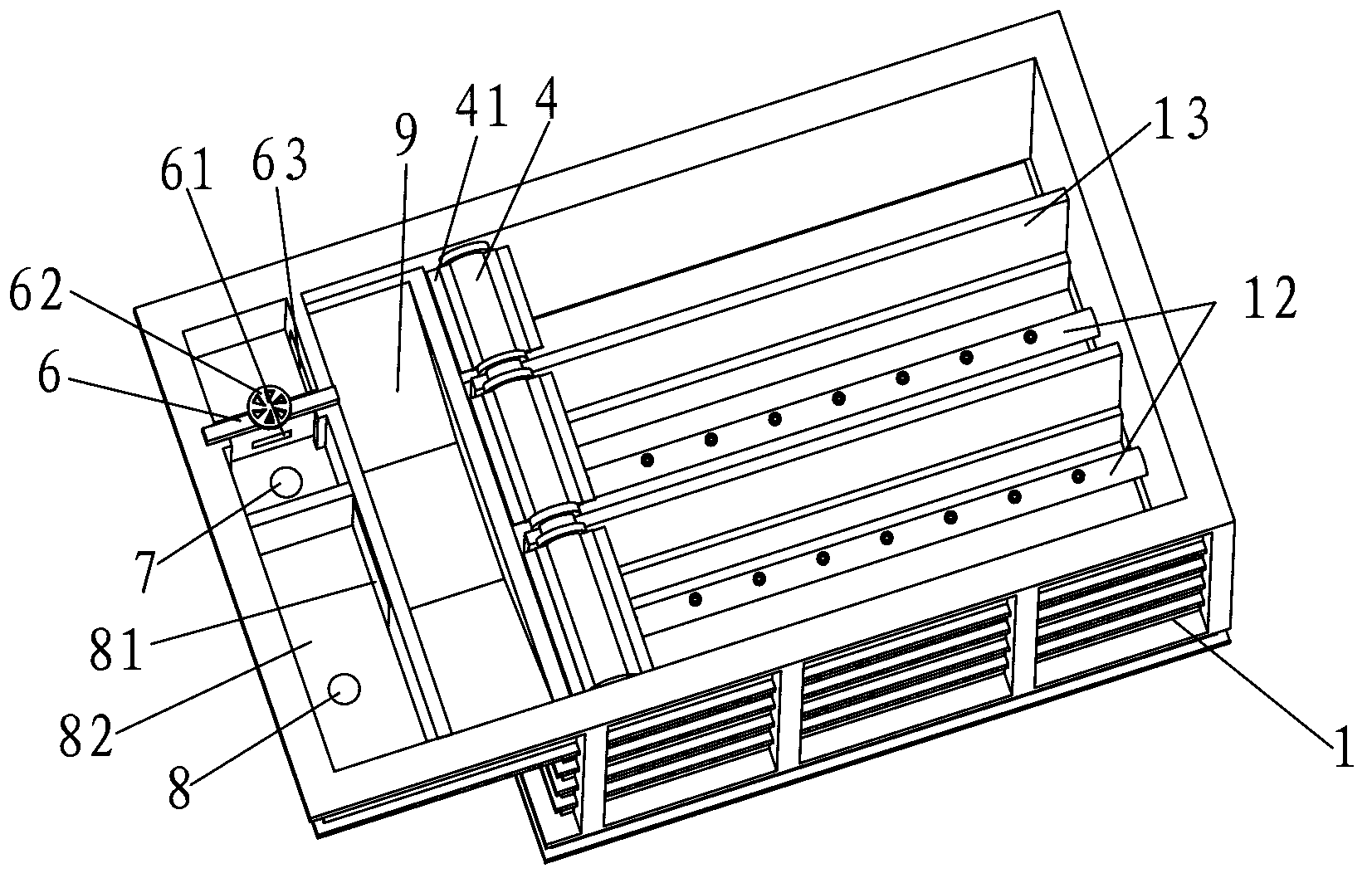

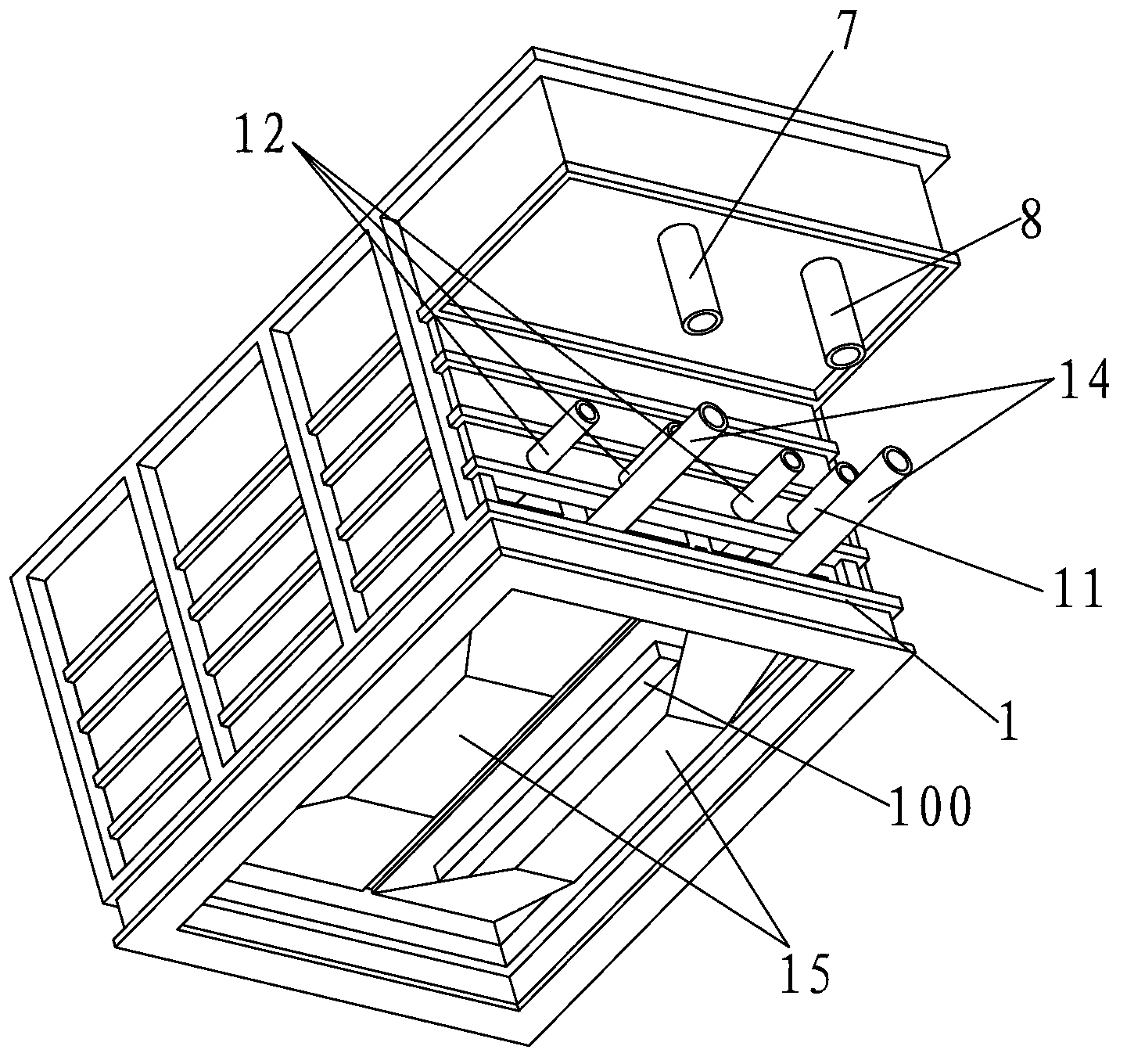

[0027] See Figure 1 to Figure 7As shown: the present invention includes a tank body 1, an electrode flocculation device 2, a slag scraping device 4, and a conical scum holding area 9, the tank body 1 is an insulating tank body, and the inside of the tank body 1 is provided with an electrode flocculation device 2, and the electrode The flocculation device 2 is composed of several electrode flocculation modules A stacked on the tank body 1. The electrode flocculation module A is composed of several parallel electrode plates 3 installed in the mesh basket 21. There is a No. 1 pole on the inner surface of both ends of the tank body 1. Plate 32 and No. 2 pole plate 33 are located above the electrode flocculation device 2 and are provided with a slag scraping device 4. The slag scraping device 4 is composed of a slag scraping shaft 41 driven by a motor 10. A flexible slag scraping plate 42 is arranged on the slag scraping shaft 41. The tank body 1 located at one end of the electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com