Method for treating sludge produced by slaughtering wastewater treatment plant by using chrysomyia megacephala maggots and material formula

A technology of golden fly and slaughtering sewage, which is applied to the material formula for implementing the above method, and utilizes golden fly maggots to treat sludge generated by slaughtering sewage treatment plants. Fast and other problems, to achieve the effect of less energy consumption, fast processing speed, and reduced odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

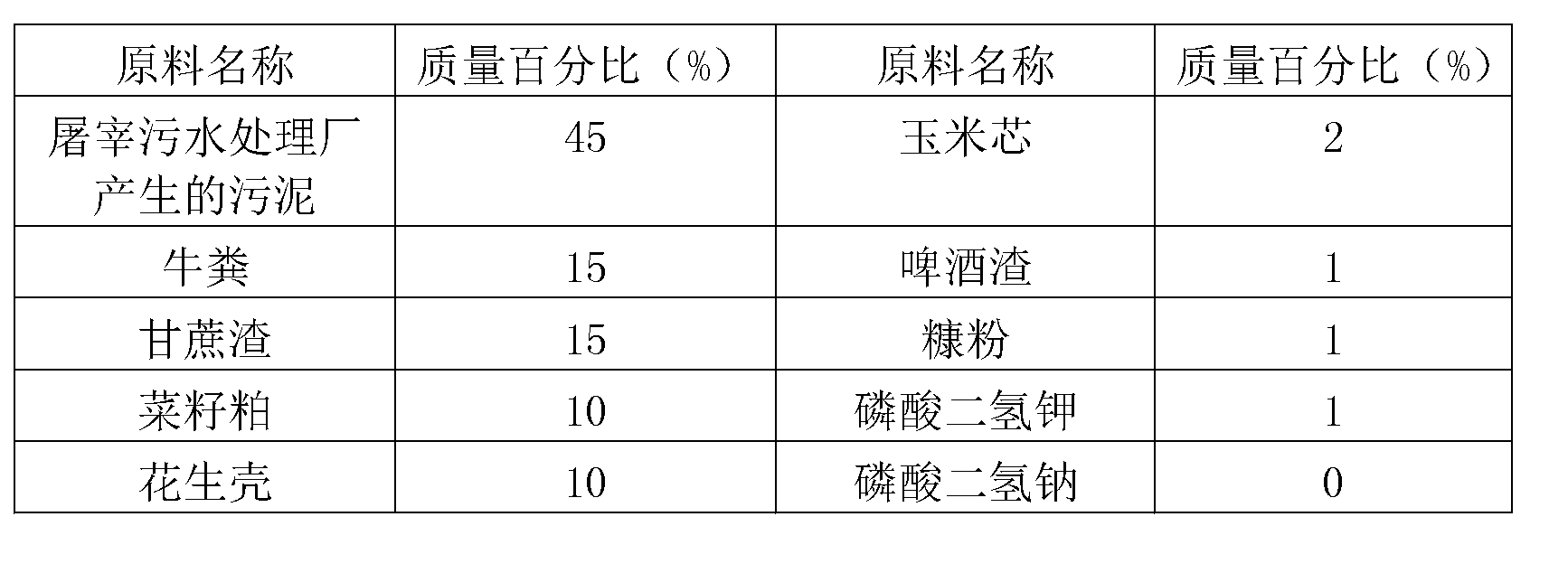

Embodiment 1

[0016]Example 1: Use plastic buckets to collect the sludge produced by the slaughter sewage treatment plant (that is, the sludge produced after the slaughter sewage is treated by the slaughter sewage treatment plant, for each embodiment, the same below), add an appropriate amount of auxiliary materials and stir to make the big head gold Fly maggot feed, the formula of feed is shown in Table 1 (the sum of the mass percentages of each component is 100%). The bran powder used is rice bran powder, and of course one or more mixtures of rice bran powder, rice bran powder, wheat bran powder, etc. Pour the feeding material into the corresponding box, the feeding material is 8cm thick, and put in an appropriate amount of golden fly eggs (that is, insert an appropriate amount of golden fly eggs on the surface of the feeding material), and the egg density is: 1g of golden fly Eggs / 1kg feed, hatched into golden fly larvae at 30°C after picking up the eggs. The eggs of Chrysocephalus chin...

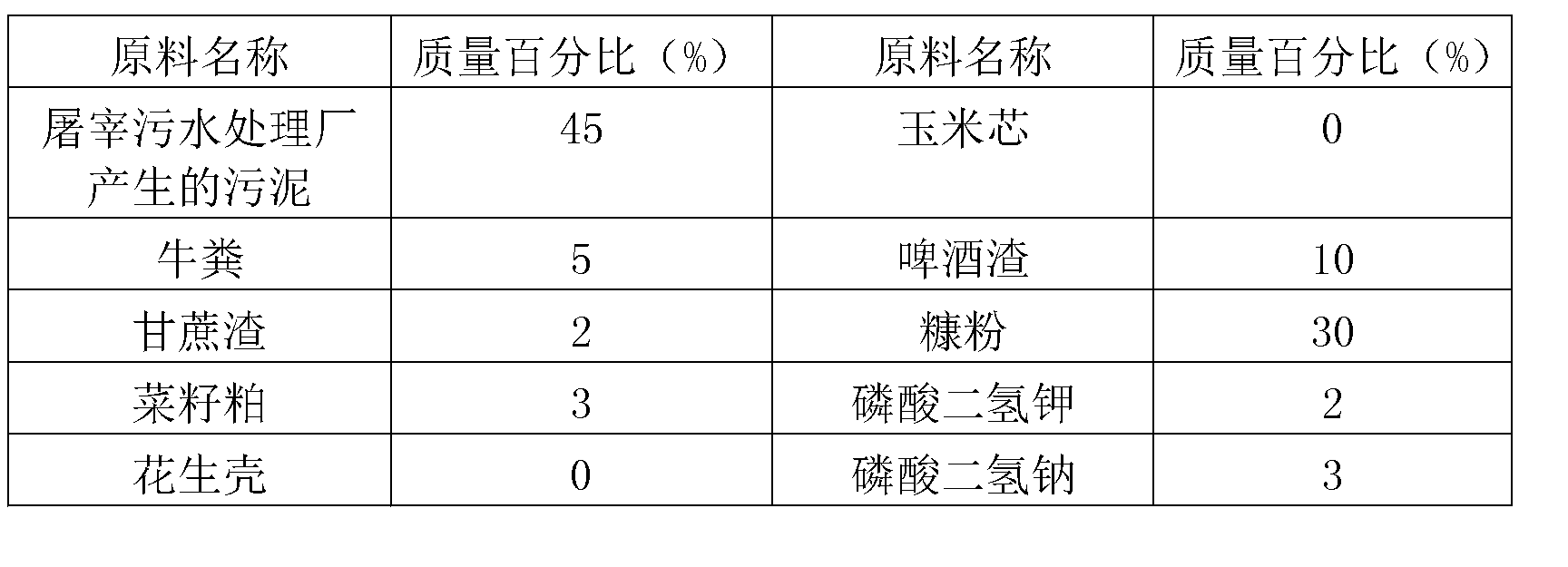

Embodiment 2

[0023] [0023] Embodiment 2: Collect the sludge that slaughtering sewage treatment plant produces with plastic barrel, add appropriate amount of auxiliary materials and stir to make Chrysophyllum macrocephala feedstuff, the formula of feedstuff is as shown in Table 2 (used bran powder is rice bran powder, of course One or more mixtures of rice bran powder, rice bran powder, wheat bran powder and other bran powders can also be used, and the proportioning ratio of several kinds of mixtures is arbitrary). Pour the feeding material into the corresponding box, the feeding material is 13cm thick, and put in an appropriate amount of golden fly eggs, the egg density is: 2.5g of golden fly eggs / 1kg feeding material, hatch at 43°C after the eggs are picked into Chrysocephala larvae. The eggs of Chrysocephalus chinensis hatched into larvae on the second day and began to eat feed. On the 4th day, put a bigger box outside the feeder box again, and sprinkle dry bran powder therein to faci...

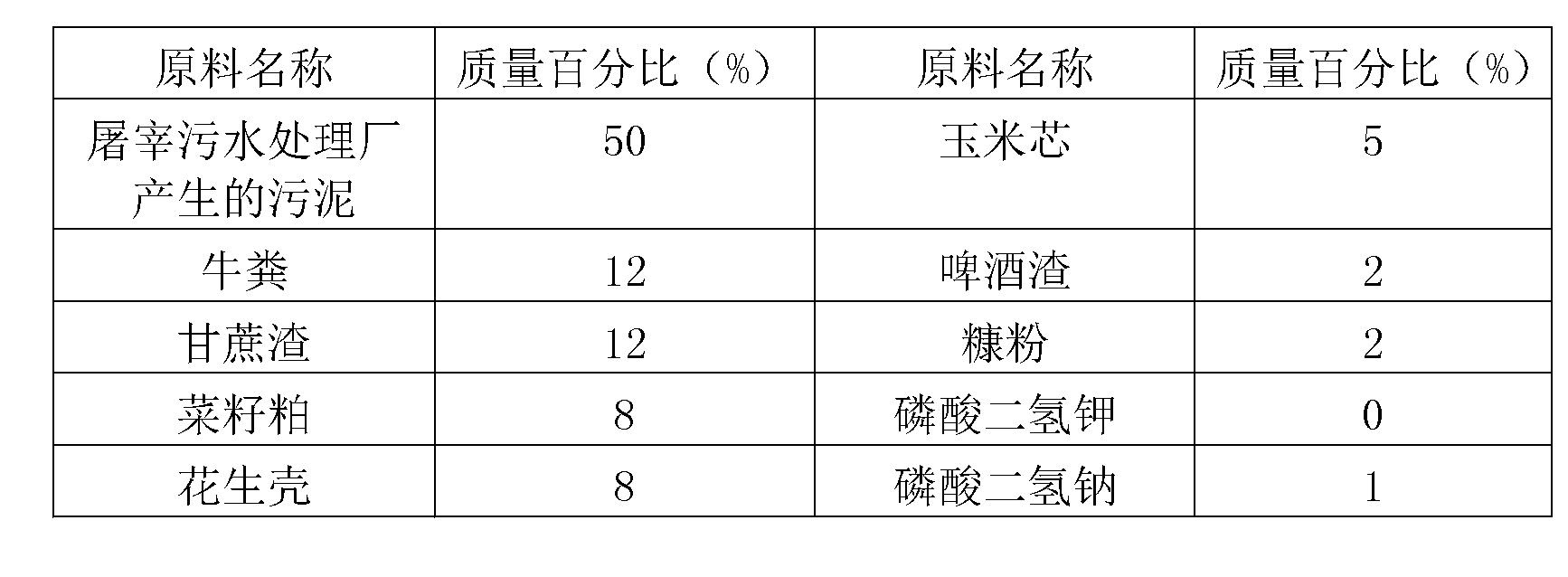

Embodiment 3

[0030] Embodiment 3: collect the sludge that slaughtering sewage treatment plant produces with plastic barrel, add appropriate amount of auxiliary material and stir and make golden fly maggot feedstuff, the formula of feedstuff is as shown in table 3 (used bran powder is wheat bran powder or Rice bran powder or a mixture of wheat bran powder and rice bran powder, the mixing ratio is arbitrary). Pour the feeding material into the corresponding box, the feeding material is 10cm thick, and put in an appropriate amount of golden fly eggs. The density of the eggs is: 3g of golden fly eggs / 1kg feeding material. After the eggs are picked, they are hatched at 50°C. Chrysanthemum fly larvae. The eggs of Chrysocephalus chinensis hatched into larvae on the second day and began to eat feed. On the 4th day, put a bigger box outside the feeder box again, and sprinkle dry bran powder therein to facilitate the collection of golden fly maggots. After 4 to 5 days, the larvae of Chrysocephala ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com