A kind of chitosan-xylan Maillard reaction product and its preparation method and application

A technology of Maillard reaction and xylan, which is applied in the fields of application, food science, food preservation, etc., can solve the problems that the reaction is difficult to control, chitosan Maillard reaction is difficult to carry out, etc., and achieve good antioxidant properties and antibacterial properties performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 50g and 25g of ionic liquid (1-butyl-3-methylimidazole chloride) in two beakers respectively, weigh 0.5g of purified chitosan and 0.5g of xylan and add them to the above-mentioned ionic liquid respectively. Heat while dissolving. After completely dissolving, mix the above two solutions completely, stir evenly, pass N 2 Oxygen in the system was excluded, and samples were taken after the reaction was carried out at 100° C. for 70 minutes under microwave irradiation conditions of 700 W. Immediately after the sample was taken out, it was cooled in an ice bath for 5 minutes, the reaction product was washed with ethanol, and the chitosan-xylan Maillard reaction product was obtained after vacuum drying.

Embodiment 2

[0025] Weigh 50g and 75g of ionic liquid (1-butyl-3-methylimidazole chloride) in two beakers respectively, weigh 0.5g of purified chitosan and 1.5g of xylan and add them to the above-mentioned ionic liquid respectively, while Heat while dissolving. After completely dissolving, mix the above two solutions completely, stir evenly, pass N 2 Oxygen in the system was excluded, and the reaction was carried out under microwave irradiation conditions of 900W and 110°C for 50min. Immediately after the sample was taken out, it was cooled in an ice bath for 7 minutes, the reaction product was washed with ethanol, and the chitosan-xylan Maillard reaction product was obtained after vacuum drying.

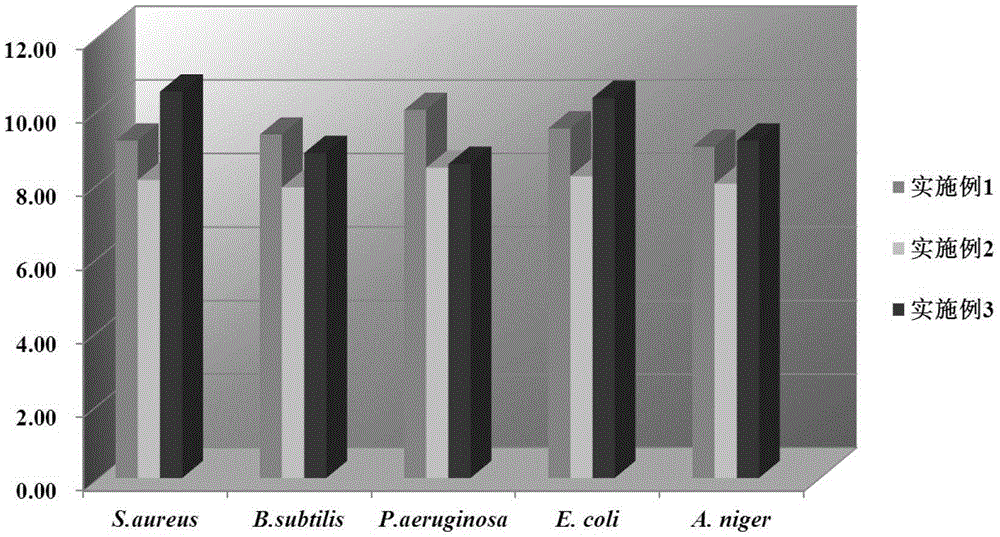

Embodiment 3

[0027] Weigh 150g and 25g of ionic liquid (1-butyl-3-methylimidazole chloride) in two beakers respectively, weigh 1.5g of purified chitosan and 0.5g of xylan and add them to the above-mentioned ionic liquid respectively. Heat while dissolving. After completely dissolving, mix the above two solutions completely, stir evenly, pass N 2 Oxygen in the system was excluded, and the reaction was carried out under microwave radiation conditions of 800W and 120°C for 60min. Immediately after the sample was taken out, it was cooled in an ice bath for 12 minutes, the reaction product was washed with ethanol, and the chitosan-xylan Maillard reaction product was obtained after vacuum drying.

[0028] Table 1. The antioxidant capacity of the Maillard reaction product of the embodiment of the present invention 1~3

[0029]

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of deacetylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com