Composite organic coating based on novolak epoxy vinyl resin and preparation method thereof

A technology of phenolic epoxy vinyl resin and phenolic epoxy vinyl, which is applied in the direction of epoxy resin coatings, coatings, anti-corrosion coatings, etc., and can solve problems such as increased product costs, decreased production efficiency, and poor thermal shock resistance , to achieve the effect of improving compression resistance, improving temperature resistance, and good self-lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

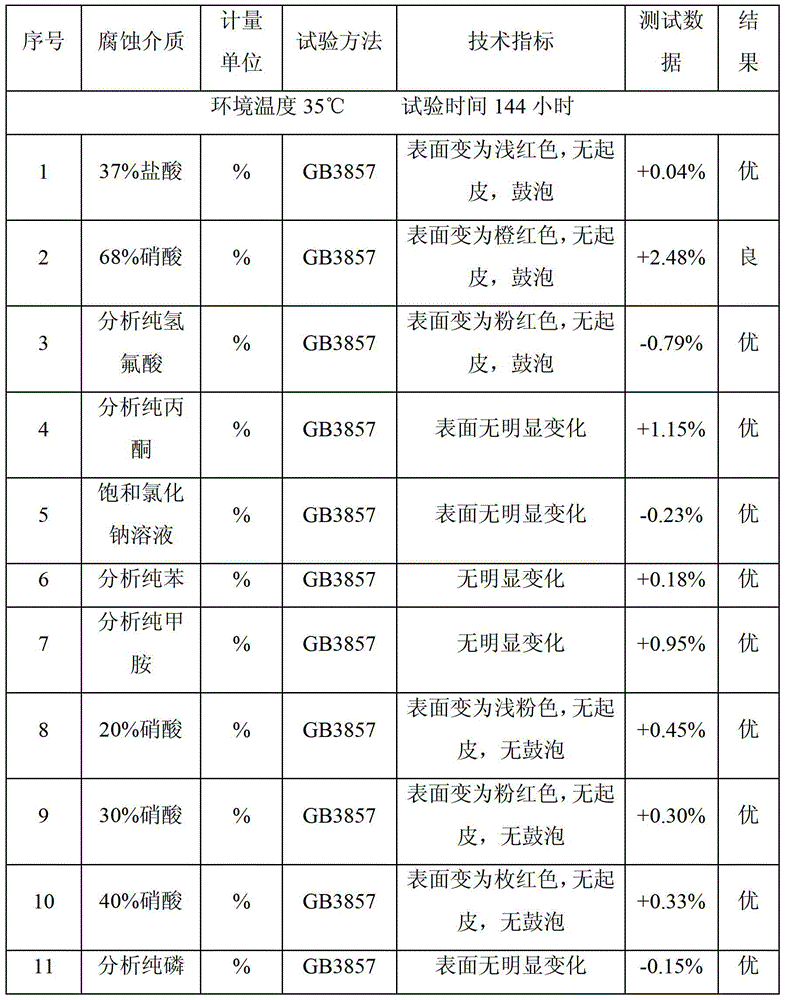

Embodiment 1

[0042] In terms of mass percentage, the modified resin formula:

[0043] Phenolic epoxy vinyl resin 25%, polyether ether ketone 5%, polyphenylene sulfide 8%, γ-methacryloxypropyl trimethoxysilane 3%, defoamer 1%, nano silicon 5%, Leveling agent 1%, barium sulfate 2%, talc 0.5%, 75 mesh C glass flake 18%, 100 mesh C glass flake 18%, 150 mesh C glass flake 3%, 200 mesh C glass flake 3%, UV absorption 0.3% of antioxidant, 0.3% of antioxidant, 2.5% of anti-settling additive, 3% of polyethylene anti-shrinking agent, and 1.4% of cobalt isooctanoate accelerator;

[0044] Curing agent formula: a mixture of methyl ethyl ketone peroxide and cyclohexanone peroxide in a mass ratio of 2:1, and the amount of resin is 1% (temperature 29°C, humidity 50%).

[0045] Material mechanical properties: shear force (adhesive force) 16MPa, stretch 35MPa, compression resistance 88MPa, Shore D hardness 86, temperature resistance 340℃, good thixotropy performance, one-time application thickness up to 3mm witho...

Embodiment 2

[0051] In terms of mass percentage, the modified resin formula:

[0052] Phenolic epoxy vinyl resin 30%, polyether ether ketone 3%, polyphenylene sulfide 3%, γ-methacryloxypropyl trimethoxysilane 1.5%, defoamer 0.5%, nano silicon 1.5%, Leveling agent 0.3%, barium sulfate 5%, talc 1.5%, 75 mesh C glass flake 13%, 100 mesh C glass flake 13%, 150 mesh C glass flake 8%, 200 mesh C glass flake 8%, UV absorption 0.8% of antioxidant, 0.8% of antioxidant, 1% of anti-settling aid, 4.1% of polyethylene anti-shrinking agent, and 5% of cobalt isooctanoate accelerator;

[0053] Curing agent formula: a mixture of methyl ethyl ketone peroxide and cyclohexanone peroxide in a mass ratio of 2:1, and the amount of resin is 2% (temperature 20°C, humidity 50%).

[0054] Material mechanical properties: shear force (adhesive force) 15MPa, tensile 38MPa, compression resistance 89MPa, Shore D hardness 87, dry environment temperature resistance 340℃, no cracks on the surface of the material, no shedding, goo...

Embodiment 3

[0060] In terms of mass percentage, the modified resin formula:

[0061] Phenolic epoxy vinyl resin 38%, polyether ether ketone 5%, polyphenylene sulfide 5%, γ-methacryloxypropyl trimethoxysilane 2%, antifoaming agent 0.8%, nano silicon 1%, Leveling agent 0.75%, barium sulfate 1.5%, talc 2%, 75 mesh C glass flakes 10%, 100 mesh C glass flakes 12%, 150 mesh C glass flakes 5.5%, 200 mesh C glass flakes 4.5%, UV absorption 0.4% of antioxidant, 0.25% of antioxidant, 1.8% of anti-settling additive, 7.5% of polyethylene anti-shrinking agent, and 2% of cobalt isooctanoate accelerator;

[0062] Curing agent formula: a mixture of methyl ethyl ketone peroxide and cyclohexanone peroxide in a 2:1 mass ratio, and the amount of resin is 1.5% (temperature 25°C, humidity 50%).

[0063] Material mechanical properties: shear force (adhesive force) 17MPa, tensile 36MPa, compression resistance 87MPa, Shore D hardness 87, dry environment temperature resistance 340℃, no cracks on the surface of the mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| draft ratio | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| draft ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com