Device for strengthening laser cladding layer by ultrasonic impact and method thereof

A technology of laser cladding and ultrasonic impact, which is applied in laser welding equipment, coating, pressure inorganic powder coating, etc., can solve problems such as uneven structure of laser cladding layer, pore cracks, large residual stress, etc., and achieve strengthening effect Outstanding, low cost, effect of eliminating residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

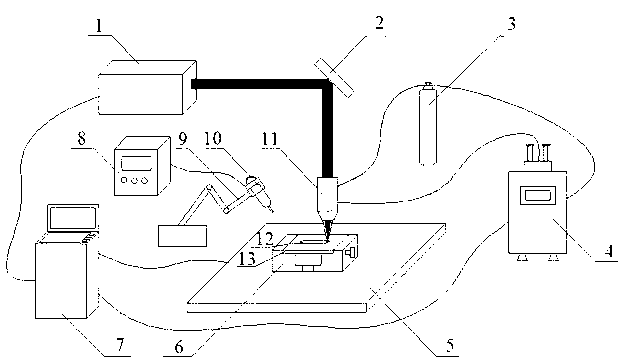

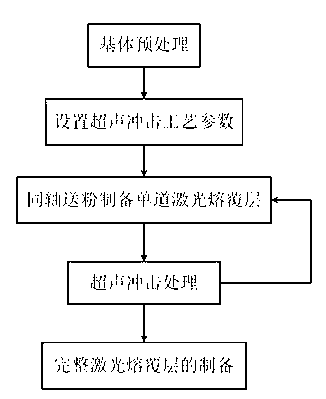

Method used

Image

Examples

Embodiment 1

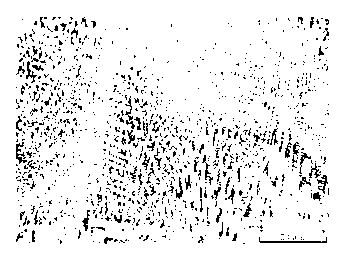

[0031]The laser cladding substrate is nickel-based superalloy GH4169, its chemical composition is shown in Table 1, and its size is 600mm×20mm×5mm. The surface of the substrate is sanded and cleaned with acetone to remove oil and impurities on the surface of the substrate and fixed on the workbench; the laser cladding powder material is nickel-based superalloy powder FGH95 with a particle size of 100-150 μm and its chemical composition is shown in the table 1. Dry the powder in a drying oven at 100-200°C for 6 hours, and add it to the powder feeder after cooling. The laser cladding process is carried out by means of coaxial powder feeding, and argon gas protection is introduced at the same time to obtain a single laser cladding layer. For laser single-pass cladding, the process parameters used are: laser power 1.5kw, scanning speed 400mm / min, powder feeding speed 24g / min, defocusing amount 15mm, spot diameter 3mm.

[0032] The sample was intercepted by wire cutting along the...

Embodiment 2

[0036] The laser single-pass cladding process is the same as that in Example 1. After the laser single-pass cladding, use an ultrasonic impact gun to impact the surface of the laser cladding layer. The ultrasonic impact process parameters are: impact frequency 20Hz, current 0.5A, impact needle diameter 1mm , the number of impact needles is 1, and the coverage rate of the laser cladding layer is guaranteed to reach 100% during impact. The metallographic structure of the obtained laser cladding layer section is as follows: Figure 4 shown.

Embodiment 3

[0038] The laser single-pass cladding process is the same as that of Example 1. After the laser single-pass cladding, use an ultrasonic impact gun to impact the surface of the cladding layer. The ultrasonic impact process parameters are: impact frequency 20Hz, current 2A, impact needle diameter 3mm, impact The number of needles is 1, and the coverage rate of the laser cladding layer is guaranteed to reach 100% during impact. The metallographic structure of the obtained laser cladding layer section is as follows: Figure 5 shown.

[0039] from image 3 It can be seen that the laser cladding layer is mainly composed of columnar dendrites and equiaxed crystals, and the distribution of grains is uneven, and the grain size in local areas is relatively large. from Figure 4 , 5 It can be clearly seen that the structure of the laser cladding layer changes from dendrite to equiaxed grain, and the grain distribution tends to be uniform and the grain size is small.

[0040] From th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com