Spinneret and method for preparing mesophase pitch-based hollow carbon fiber

A pitch-based, spinneret technology, used in hollow filament manufacturing, fiber processing, fiber chemical characteristics, etc., can solve the problems of difficult to close the gap of the C-shaped melt, high viscosity, fast cooling and solidification, etc. The effect of simple hole structure, uniform wall thickness and complete structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Separately filter petroleum catalytic cracking residue and ethylene tar to remove catalyst particles and free carbon solid impurities, weigh 700g and 300g respectively, mix them, and distill for 30min at a pressure of 24kPa and a temperature of 290°C to remove some light components . Put the obtained heavy components into the reaction kettle, raise the temperature to 420°C at a heating rate of 3°C / min, and carry out co-condensation at a constant temperature for 6 hours to obtain a co-condensation pitch, and then put the co-condensation pitch under the conditions of a pressure of 24kPa and a temperature of 360°C Distilled down for 60 minutes to remove part of the light components to obtain a mesophase pitch with a softening point of 290°C. The optical anisotropy region of the mesophase pitch is 96%. Analysis of its group composition reveals that the soluble content of benzene is 6.5%. Benzene insoluble-quinoline insoluble matter is 13.6%, and quinoline insoluble matter i...

Embodiment 2

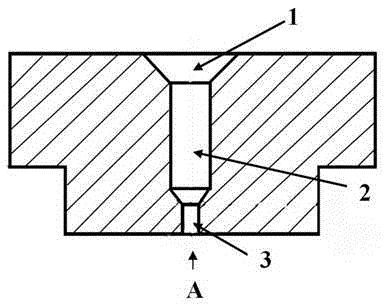

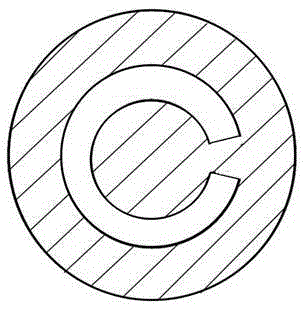

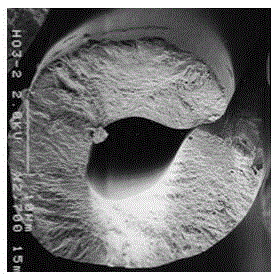

[0026] Get 12 grams of the mesophase pitch raw material obtained in Implementation 1, grind and pass through a 120-mesh standard sieve, get 10 grams and pack it into the spinning barrel, and feed the nitrogen gas with a purity of 99.999% in the barrel. The improved C-type spinneret of the present invention is used to spin molten pitch. The gap between the slits of the C-type spinneret hole of the spinneret is equal to 100 μm, the outer diameter is 700 μm, the inner diameter is 500 μm, the length of the slit hole is 800 μm, the spinning temperature is 320 ° C, and the spinning speed is 5.5 m / s. Continuous spinning for 10 minutes without continuous filaments. The obtained hollow pitch fiber had an outer diameter of 24 μm and an inner diameter of 7.7 μm. The hollow pitch fiber was heated up at 2°C / min in an air atmosphere, and then kept at a constant temperature for 90 minutes after the temperature was raised to 310°C for non-melting treatment. ?1 After the temperature was rais...

Embodiment 3

[0028] Take 12 grams of the mesophase pitch raw material prepared in Example 1, pass through an 80-mesh standard sieve after grinding, take 7 grams and put it into the spinning barrel, and start heating after the barrel is fed with high-purity nitrogen. Hollow pitch fibers are spun from molten pitch through spinneret holes. The gap between the slits of the C-type spinneret hole of the spinneret is equal to 100 μm, the inner diameter is 600 μm, the outer diameter is 800 μm, the length of the slit hole is 900 μm, the spinning temperature is 330 ° C, and the spinning speed is 5.8 m / s. Continuous spinning for 10 minutes without continuous filaments. The obtained hollow pitch fiber had an outer diameter of 30 μm and an inner diameter of 5.0 μm. Raise the temperature of the pitch fiber at 3°C / min in an air atmosphere, and then heat it up to 310°C for 90 minutes at a constant temperature for non-melting treatment, and then under the protection of 99.999% pure nitrogen from room temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com