Pretreatment method of polyester fiber surface

A technology of surface pretreatment and polyester fiber, which is applied in fiber treatment, fiber type, textiles and papermaking, etc., can solve the problem of low bond strength between highly toxic polyester fiber and rubber, and improve production continuity and efficiency. Effect of avoiding high toxicity and improving adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

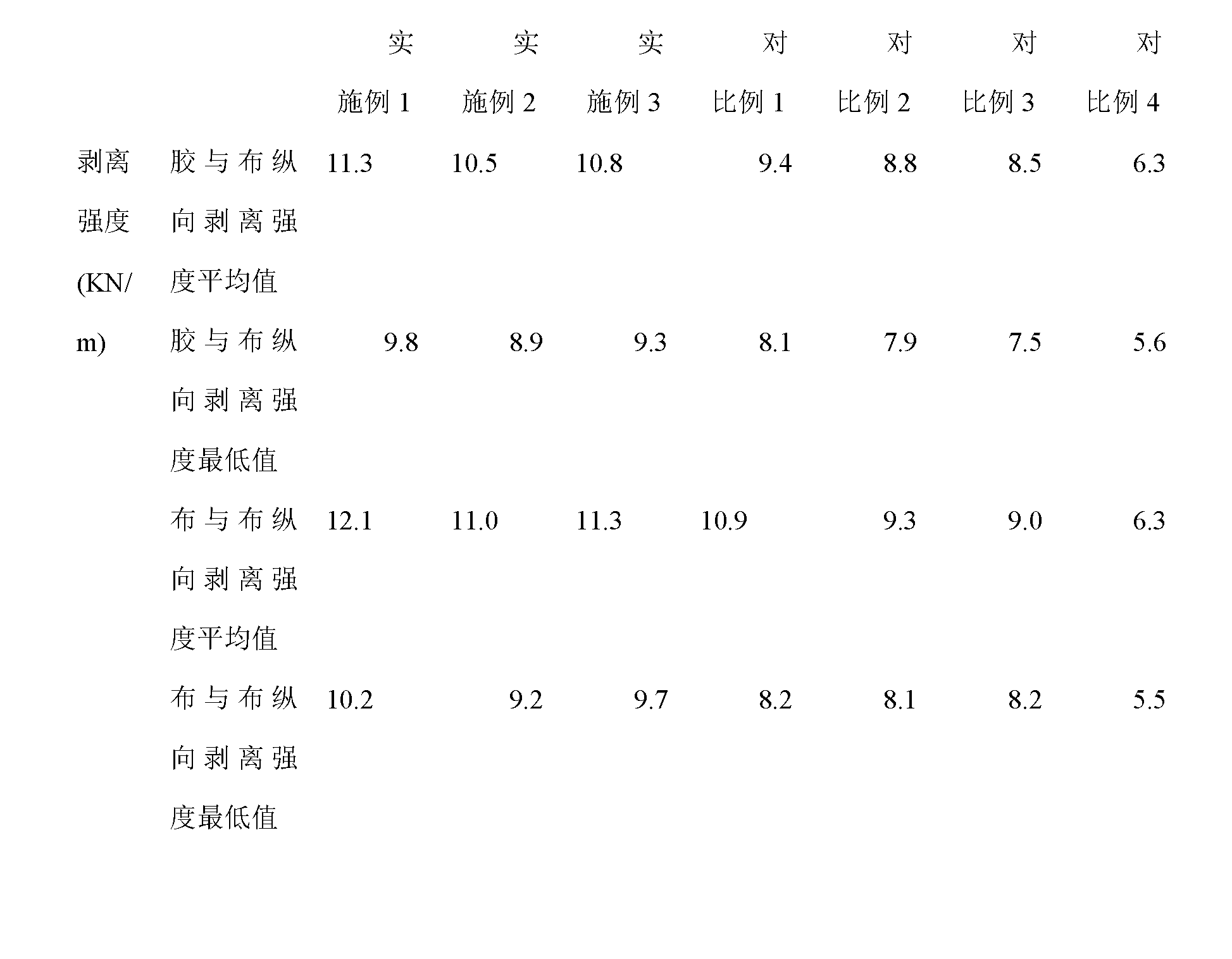

Examples

Embodiment 1

[0032]Deposit polydopamine on the surface: prepare 1g / L dopamine hydrochloride (commercially available) aqueous solution, adjust pH=8.5 with tris (commercially available), put 10cm*10cm polyester cord (commercially available) into the dopamine solution, React for 4 hours at 30°C under aerobic and stirring conditions, take out the polyester cord and wash and dry it with water.

[0033] Grafting epoxy groups: Add 25g of epoxy resin (commercially available) to 1L of deionized water to configure the solution, adjust pH=8.5 with NaOH (commercially available), immerse the polyester cord with polydopamine deposited on the surface into the solution, pass through the water bath Heat to control the reaction temperature to 80° C., stir for 8 hours, and take out the polyester cord for washing and drying.

[0034] Dipping treatment: Add water, resorcinol, formaldehyde, and sodium hydroxide into a stirring tank, stir evenly, and react at 40°C for 4 hours to obtain a phenolic resin solution....

Embodiment 2

[0045] Deposit polydopamine on the surface: prepare 1g / L dopamine hydrochloride (commercially available) aqueous solution, adjust pH=8.5 with tris (commercially available), put 10cm*10cm polyester cord (commercially available) into the dopamine solution, React for 8 hours at 30°C under aerobic and stirring conditions, take out the polyester cord and wash and dry it with water.

[0046] Grafting Si69: Add 10g of silane coupling agent Si69 (commercially available) into 1L of deionized water and stir evenly, adjust the pH of the reaction solution to 11 with NaOH, immerse the polyester cord with polydopamine deposited on the surface into the reaction solution, and heat it in a water bath The reaction temperature was controlled at 20° C., the reaction was stirred for 8 hours, and the polyester cord was taken out for washing and drying.

[0047] The formula and steps of dipping treatment and preparation of strip test strips are the same as those shown in Example 1.

Embodiment 3

[0049] Deposit polydopamine on the surface: prepare 1g / L dopamine hydrochloride (commercially available) aqueous solution, adjust pH=8.5 with tris (commercially available), put 10cm*10cm polyester cord (commercially available) into the dopamine solution, React for 12 hours at 30°C under aerobic and stirring conditions, take out the polyester cord and wash and dry it with water.

[0050] Graft Si69: Add 10g of silane coupling agent Si69 (commercially available) into 1L of deionized water and stir evenly, adjust the pH of the reaction solution to 7.5 with NaOH, immerse the polyester cord with polydopamine deposited on the surface into the reaction solution, and heat it in a water bath Control the reaction temperature to 80° C., stir and react for 8 hours, take out the polyester cord and wash and dry it with water.

[0051] The formula and steps of dipping treatment and preparation of strip test strips are the same as those shown in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com