A kind of negative electrode of lithium ion battery and lithium ion battery

A lithium-ion battery and negative electrode technology, which is applied to battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of reduced cycle life, poor rate performance, and reduced expansion, and achieve low expansion rate and low expansion rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

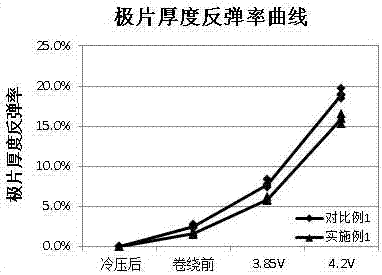

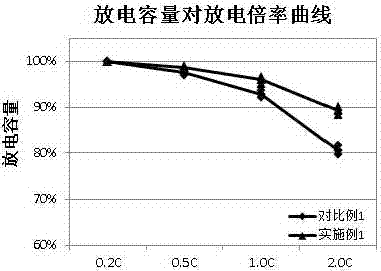

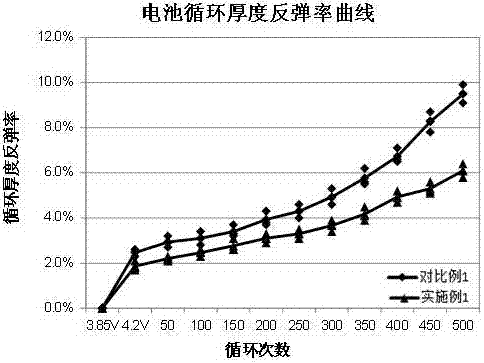

[0034] Embodiment 1, a lithium ion battery negative electrode, comprising a negative electrode current collector and a negative electrode active material layer coated on the negative electrode current collector, the negative electrode active material layer comprising a negative electrode active material, a conductive agent, a polymer thickener, and a water emulsion type polymer Material binder and water-soluble polymer binder, the water-soluble polymer binder is polyethyleneimine, and the weight ratio of the water-emulsion polymer binder and the water-soluble polymer binder is 10:90 ~90: 10.

[0035] The preparation of the negative electrode: The negative electrode slurry formula is based on the weight percentage of the dry material, consisting of 2% styrene butadiene rubber emulsion, 1.5% polyethyleneimine, 0.5% sodium carboxymethyl cellulose, 1% conductive carbon black, 95% negative electrode active material It is composed of five parts, in which the negative electrode active m...

Embodiment 2

[0047] The difference between Example 2 and Example 1 is that the preparation process of the negative electrode in this example is that the negative electrode slurry formula is based on the weight percentage of dry material, consisting of 2% nitrile rubber emulsion, 1.5% butadiene rubber emulsion, and 2% Polyethyleneimine, 0.5% carboxymethyl cellulose, 1% carbon fiber, 93% negative electrode active material consists of five parts, of which the negative electrode active material uses natural graphite and graphitized carbon fiber, the weight average molecular weight of polyethyleneimine is about 100,000g / mol, the pH value of the aqueous solution with a mass concentration of 5% is in the range of 9-12, the substitution degree of carboxymethyl cellulose is in the range of 0.8-1.0, and the aqueous solution with a mass concentration of 1% is at 25℃ The viscosity is in the range of 1000-3000mPa.s. In the slurry configuration process, the solvent is deionized water, and water accounts...

Embodiment 3

[0051] Example 3 is different from Example 2: The preparation process of the negative electrode in this example is that the negative electrode slurry formula is based on the weight percentage of the dry material, consisting of 2% butadiene rubber emulsion, 2% polyethyleneimine, and 1% It consists of five parts: hydroxyethyl cellulose, 1% carbon nanotubes, and 94% negative electrode active material. The negative electrode active material uses graphitized mesophase carbon beads and amorphous carbon. The weight average molecular weight of polyethyleneimine is about 5,000 g / mol, the pH value of an aqueous solution with a mass concentration of 5% is in the range of 9-12, the degree of substitution of hydroxyethylcellulose is in the range of 0.8-1.0, and an aqueous solution with a mass concentration of 1% is at 25°C The viscosity is in the range of 1000-3000mPa.s. In the slurry configuration process, the solvent is deionized water, and water accounts for 60% of the total slurry mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com