Cu2O-TiO2/reduced graphene oxide ternary complex, and preparation method and applications thereof

A ternary compound, cu2o-tio2 technology, applied in the field of photocatalysis, can solve the problems that restrict the wide application of nano-TiO, easy to compound powder materials, easy agglomeration, and influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Weigh 0.5g of sodium nitrate and add it to 23mL of concentrated sulfuric acid, then add 1g of graphite under stirring, then slowly add 3g of potassium permanganate under ice bath cooling and stirring, and continue stirring in the ice bath for 2h. Remove the ice bath, heat up to 35°C, keep warm and stir for 2h. Slowly add 46mL of deionized water under stirring, raise the temperature to 98°C, keep warm for 15min, then further dilute to 140mL with warm deionized water, add about 10mL of 30% hydrogen peroxide to obtain a bright yellow mixture, and centrifuge. Finally, the GO was washed three times with hydrochloric acid solution with a volume ratio of 1:10, washed with water six times, and dried in vacuum at 45 °C for 24 h to obtain GO.

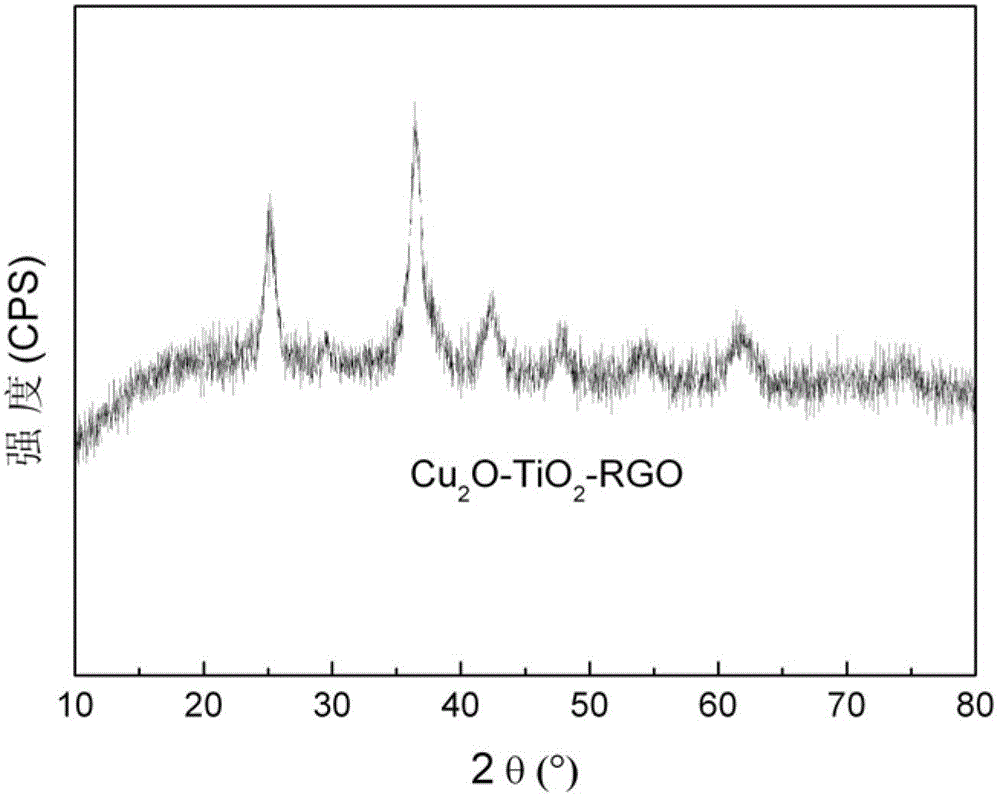

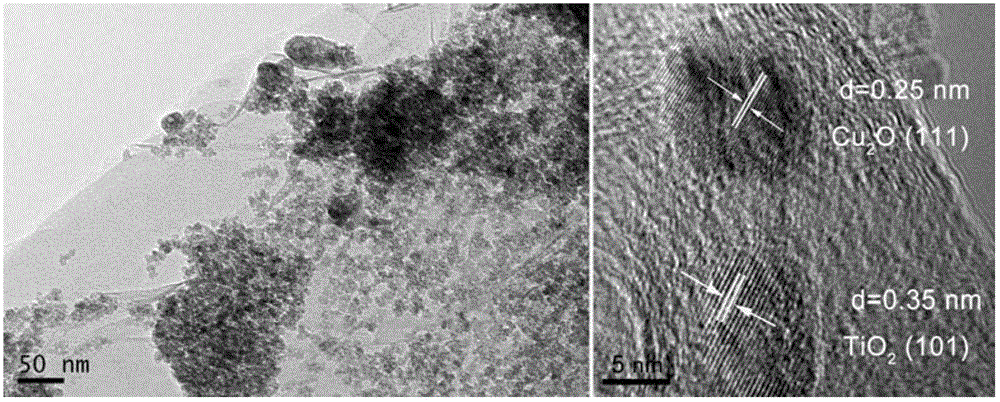

[0020] Put 0.5g GO in 65mL of absolute ethanol for ultrasonic treatment for 60min, add dropwise 3.1875g of butyl titanate, stir at room temperature for 40min, then add 0.8mL of deionized water, continue stirring for 40min, and then place i...

Embodiment 2

[0041] The preparation method of GO is the same as in Example 1.

[0042] Change the consumption of starting material by the method of embodiment 1 and prepare 60wt%Cu 2 O-30wt%TiO 2 - 10wt% RGO photocatalyst.

[0043] The evaluation method of the photocatalytic activity of the catalyst is the same as in Example 1.

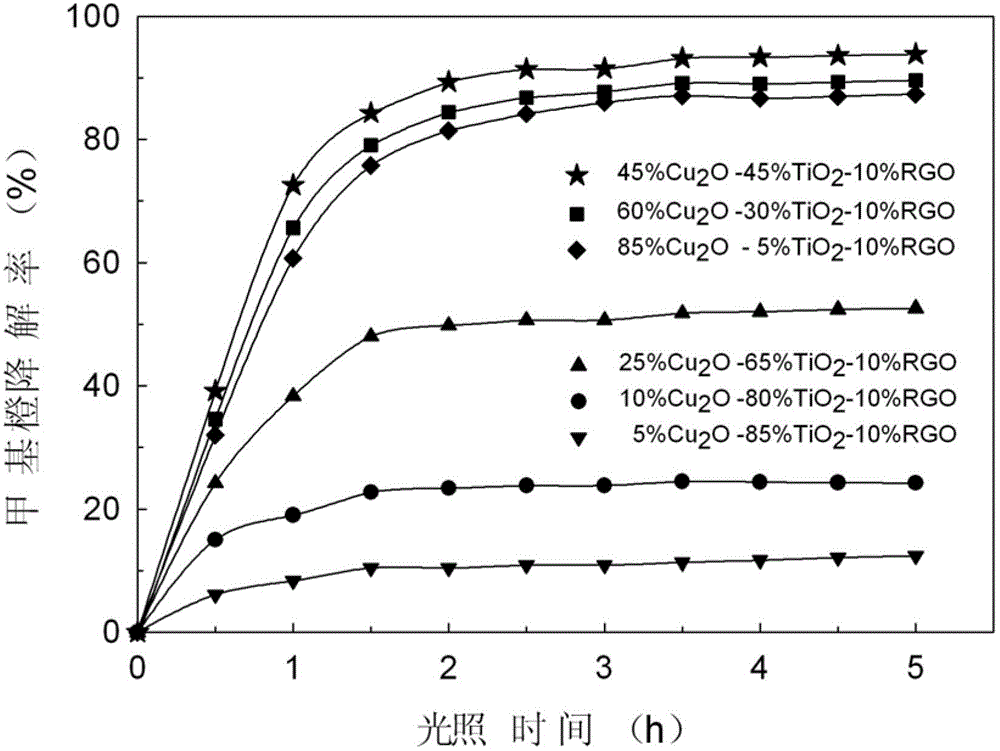

[0044] The photocatalytic reaction system was irradiated with visible light for 5 hours, and the degradation rate of methyl orange reached 89.6%.

Embodiment 3

[0046] The preparation method of GO is the same as in Example 1.

[0047] Change the consumption of starting material by the method of embodiment 1 and prepare 85wt%Cu 2 O-5wt%TiO 2 - 10wt% RGO photocatalyst.

[0048] The evaluation method of the photocatalytic activity of the catalyst is the same as in Example 1.

[0049] The photocatalytic reaction system was irradiated with visible light for 5 hours, and the degradation rate of methyl orange reached 87.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com