A kind of preparation method and application of mild reaction type aldehyde and ketone resin

The technology of aldehyde-ketone resin and aldehyde-ketone type is applied in the field of chemical grouting material preparation, which can solve the problems of boiling and detonation, low acetone, etc., and achieve the effects of reducing volatility performance, solving brittleness and simple construction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

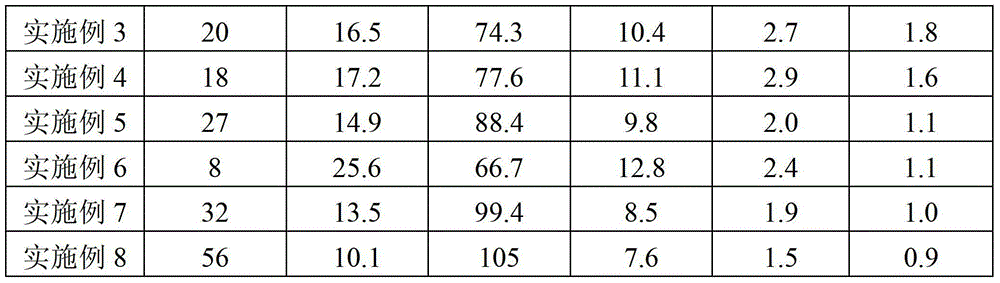

Examples

Embodiment 1

[0024] Barium hydroxide and MgO-NaOH, Rb 2 O is mixed according to the molar ratio of 1:1:1 to obtain a super-alkaline catalyst, after furfural and methyl ethyl ketone are mixed according to the molar ratio of 2:1, a mixed solution of aldehyde and ketone is obtained; under stirring conditions at 20°C, within 2.5 hours Continuously add the superbasic catalyst to the aldehyde-ketone mixture, and the mass ratio of the superbasic catalyst to the superbasic catalyst is 600:1. Continue to react for 3.5 hours to obtain aldehyde and ketone resin. No implosion phenomenon occurred during the whole reaction process.

[0025] Mix and stir 49.9 parts of epoxy resin E-44, 50 parts of aldehyde and ketone resin, and 0.1 part of aluminate coupling agent DN-211 to obtain component A; mix 83 parts of main curing agent N, N-diethylaminopropylamine, 9 parts of performance control curing agent low-molecular polyamide 651#, 3 parts of curing accelerator triethanolamine, 5 parts of curing accelerat...

Embodiment 2

[0027] Sodium ethoxide and sodium hydroxide, Cs 2 O is mixed according to a molar ratio of 1:1:1.5 to obtain a super-alkali catalyst, and after mixing acetylacetone, furfural and benzaldehyde according to a molar ratio of 5:2:3, a mixed solution of aldehyde and ketone is obtained; at 40° C. under stirring conditions , within 1 hour, continue to add the superbasic catalyst to the aldehyde and ketone mixture, and the mass ratio of the superbasic catalyst to the superbasic catalyst is 20:1. Continue to react for 4 hours to obtain aldehyde and ketone resin. No temperature rise occurred during the entire reaction.

[0028] Mix and stir 18 parts of epoxy resin F-51, 77 parts of aldehyde and ketone resin, and 5 parts of titanate coupling agent CT-56 to obtain component A; mix 77 parts of main curing agent diethylenetriamine and 5 parts of performance control curing Agent modified amine 593#, 11.5 parts of performance control curing agent modified amine 810#, and 6.5 parts of methyl...

Embodiment 3

[0030] Mix calcium hydroxide, CaO, and SrO according to the molar ratio of 2.5:1:0.5 to obtain a super-alkali catalyst, and mix isophorone and glutaraldehyde according to the molar ratio of 1.2:1 to obtain a mixed solution of aldehyde and ketone; at 30 Under the condition of stirring at ° C, within 1 hour, continue to add the superbasic catalyst to the aldehyde and ketone mixture, and the mass ratio of the superbasic catalyst to the superbasic catalyst is 80:1. Continue to react for 3.5 hours to obtain aldehyde and ketone resin. No implosion phenomenon occurred during the whole reaction process.

[0031] 25 parts of epoxy resin E-44, 35 parts of epoxy resin E-51, 39 parts of aldehyde and ketone resin, 0.3 parts of silane coupling agent KH550, 0.5 parts of titanate coupling agent CT-56, 0.2 parts of aluminate The coupling agent GR-AL18 is mixed and stirred to obtain the first component; 10 parts of the main curing agent tetraethylenepentamine, 45 parts of the aromatic amine pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com