Edible fish skin collagen antibacterial film containing thyme essential oil

A fish skin collagen and essential oil technology, applied in animal/human protein, organic chemistry, flexible coverings, etc., to achieve good antibacterial activity, prolong fresh-keeping period, and prolong shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Weigh 1.2 g of collagen and dissolve it with 15 ml of distilled water in a stirring water bath at 45°C to make a collagen aqueous solution; homogeneously dissolve 0.6 ml of thyme essential oil in 15 ml of distilled water containing 0.075 g of soybean lecithin to make thyme essential oil solution, and then mix the two, add 0.3 g glycerin as a plasticizer, stir evenly, degas by ultrasonication for 30 min, and keep warm at 45 °C. Pipette 10 ml of casting solution each time and spread it on a plexiglass frame of 120 mm×80 mm×2 mm to form a film. Peel off the frame to obtain the collagen antibacterial film. The antibacterial activity of the membrane was measured by the filter paper method, and the membrane was cut into a circle of 12 mm to investigate the antibacterial effect of the antibacterial membrane on Escherichia coli and Staphylococcus aureus.

Embodiment 2

[0019] Weigh 1.2 g of collagen and dissolve it with 15 ml of distilled water in a stirring water bath at 45°C to make a collagen aqueous solution; homogeneously dissolve 1.2 ml of thyme essential oil in 15 ml of distilled water containing 0.075 g of soybean lecithin to make thyme essential oil solution, and then mix the two solutions, add 0.3 g glycerin as a plasticizer, stir evenly, degas by ultrasonication for 30 min, and keep warm at 45°C. Pipette 10 ml of casting solution each time and spread it on a plexiglass frame of 120 mm×80 mm×2 mm to form a film. Peel off the frame to obtain the collagen antibacterial film. The antibacterial activity of the membrane was measured by the filter paper method, and the membrane was cut into a circle of 12 mm to investigate the antibacterial effect of the antibacterial membrane on Escherichia coli and Staphylococcus aureus.

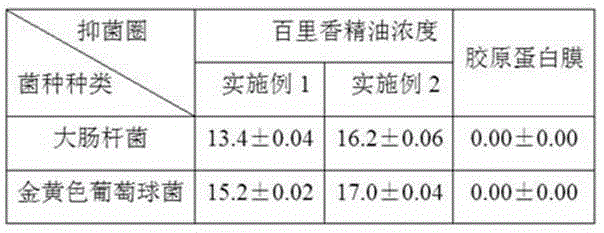

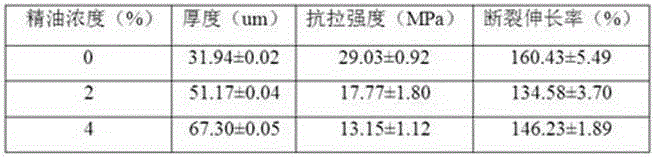

[0020] Table 1 The inhibition zones of the antibacterial films prepared under different conditions

[0021]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com