High-strength epoxy resin iron-core glue used for amorphous transformer

A technology of epoxy resin and transformer, which is applied in the direction of epoxy resin glue, non-polymer adhesive additives, adhesives, etc., and can solve problems such as easy cracking and weak impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

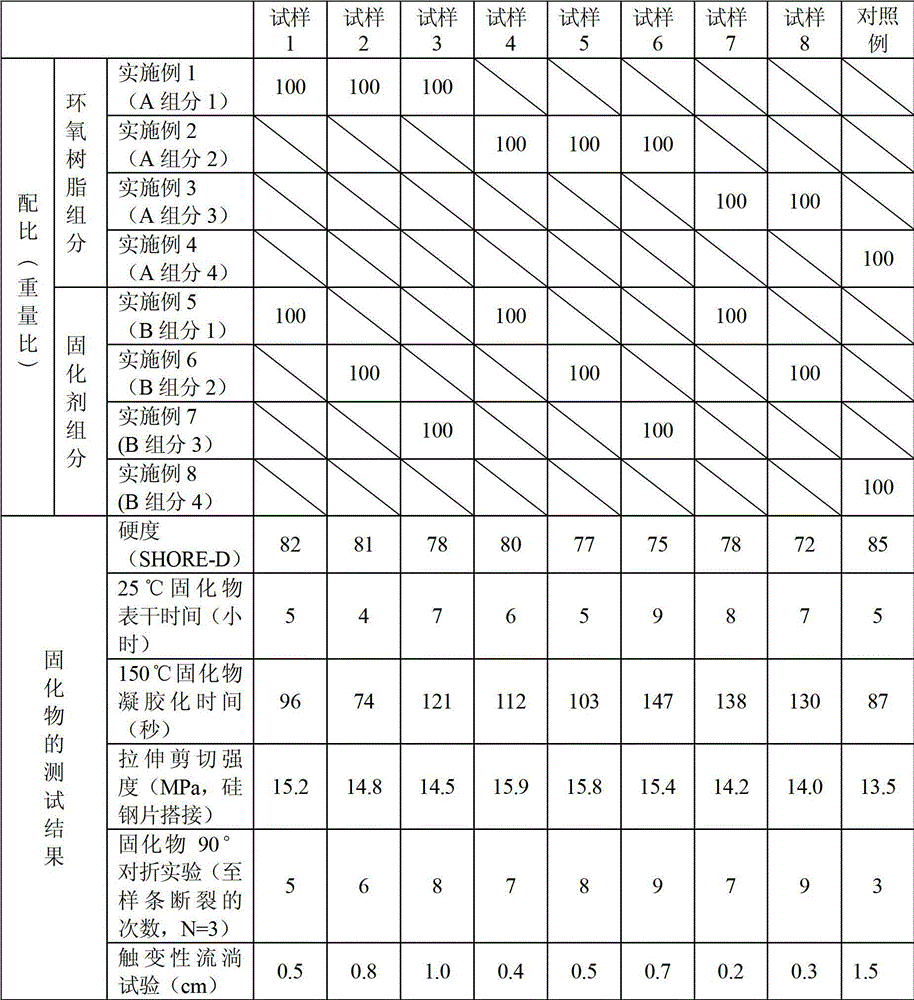

Examples

preparation example Construction

[0041] The preparation method of the high-strength epoxy resin core adhesive for amorphous transformer comprises the following process steps:

[0042] (1) Preparation of liquid isoprene toughening agent: After pre-baking liquid isoprene rubber and reactive epoxy diluent in a drying room at 80°C for more than 3 hours, the ratio by weight is 1:1 Pour it into a high-speed disperser together, and disperse and stir at a speed of 300 rpm for more than 30 minutes until the mixed liquid becomes clear and integrated;

[0043] (2) Preparation of component A: put bisphenol A epoxy resin, liquid isoprene toughening agent, gray glue, defoamer, and coupling agent liquid materials prefabricated in step (1) in a planetary mixer at 90 After heating and stirring at ℃ for 30 minutes, add the thixotropic material, first stir at low speed for 20 minutes, then raise the temperature to 80℃, vacuum and stir at high speed for 20 minutes, move to the hydraulic discharge machine, and press the material ...

Embodiment 1

[0054] Example 1 (A component 1): Add 280Kg bisphenol A type epoxy resin (YD-128 manufactured by Kunshan Guodu Chemical) into a stainless steel reaction kettle with electric heating and vacuum device planetary mixer (Foshan Jinyinhe Machinery, XJB600) , epoxy equivalent 190g / eq), heated to 90°C, then added 2Kg gray glue, 40Kg liquid isoprene toughening agent, 0.6Kg defoamer (Deqian Chemical Defom5300), silane coupling agent KH550 and KH560 0.6Kg (Nanjing Shuguang Chemical Industry Co., Ltd.), stir quickly at 300 rpm for 30 minutes, add 80Kg of thixotropic powder nano-scale rubber and plastic calcium carbonate (Huzhou Linghua Group, D50≤0.5μm), first mix at 200 rpm Stir for 20 minutes, then raise the temperature to 80°C, evacuate to above -0.08MPa, stir at a speed of 300 rpm for 20 minutes, discharge through a hydraulic discharge machine, and pass through a three-roll machine (Changzhou Dongfang Jingda Machinery Factory, S260 ) Grind 1 time into a uniform rubber compound.

Embodiment 2

[0055] Example 2 (A component 2): Add 256Kg bisphenol A type epoxy resin (YD-128 manufactured by Kunshan Guodu Chemical) into a stainless steel reactor of a planetary mixer (Foshan Jinyinhe Machinery, XJB600) with electric heating and vacuum device , epoxy equivalent 190g / eq), heated to 90°C, then added gray glue 2Kg, liquid isoprene toughening agent 64Kg, defoamer 0.6Kg (Deqian Chemical Defom5300), silane coupling agent KH550 and KH560 0.6Kg (Nanjing Shuguang Chemical Industry Co., Ltd.), stir quickly at 300 rpm for 30 minutes, add 80Kg of thixotropic powder nano-scale rubber and plastic calcium carbonate (Huzhou Linghua Group, D50≤0.5μm), first mix at 200 rpm Stir for 20 minutes, then raise the temperature to 80°C, evacuate to above -0.08MPa, stir at a speed of 300 rpm for 20 minutes, discharge through a hydraulic discharge machine, and pass through a three-roll machine (Changzhou Dongfang Jingda Machinery Factory, S260 ) Grind 1 time into a uniform rubber compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com