Method for preparing biological activity micro-arc oxidation ceramic coating with macroscopic/microcosmic double-stage pore structure on surface of medical titanium through two-step method

A technology of micro-arc oxidation and pore structure, which is applied in surface reaction electrolytic coatings, coatings, electrolytic coatings, etc., can solve the problems of complex preparation process and non-biological activity of coatings, and achieves simple method, guaranteed functionality, The effect of increasing the roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

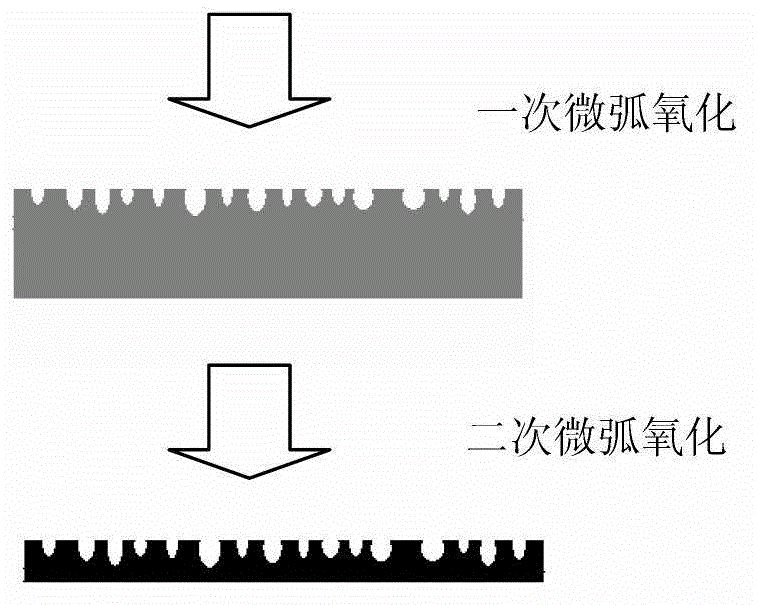

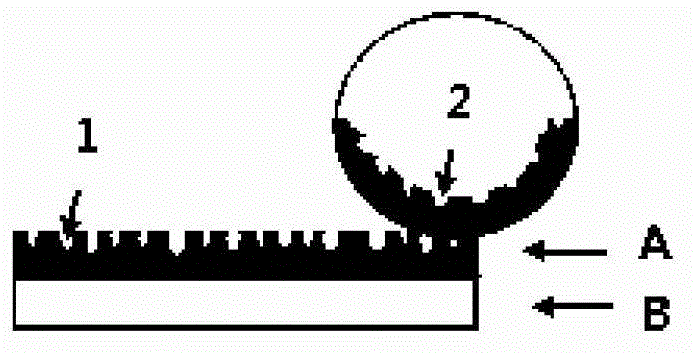

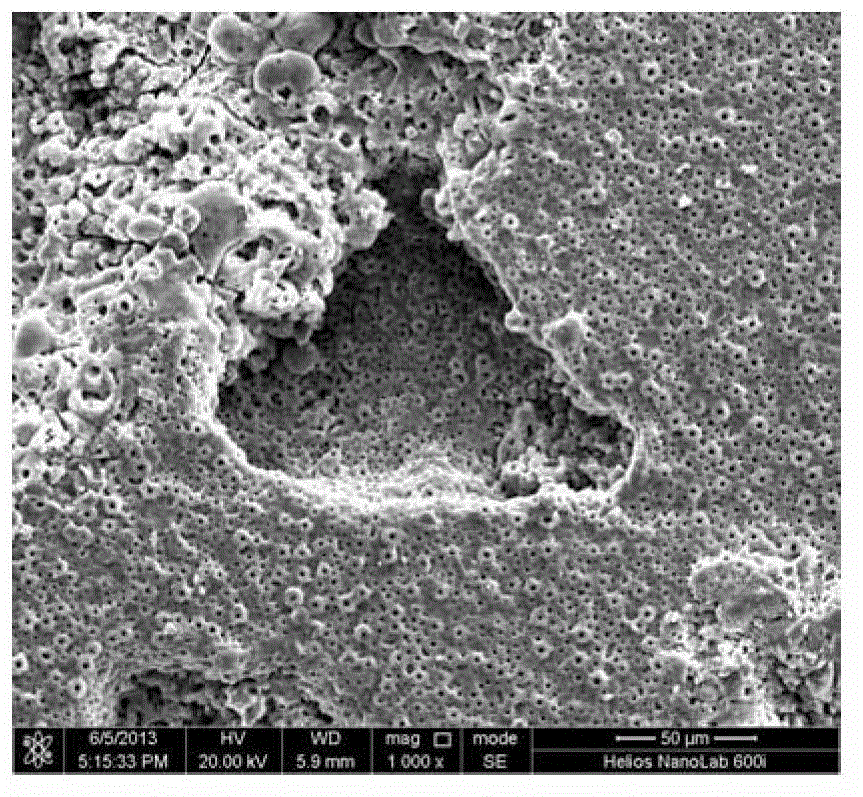

[0016] Specific implementation mode one: combine figure 1 In this embodiment, the method for preparing a bioactive micro-arc oxidation ceramic coating with a macroscopic / microscopic dual-stage pore structure by a two-step method on the surface of medical titanium is carried out according to the following steps:

[0017] 1. Titanium sample surface pretreatment: Use 300#, 700#, 1000# and 1200# sandpaper to grind and polish the titanium flat sample sequentially on the metallographic sample pre-grinder to obtain the polished titanium flat sample, and then Use acetone, absolute ethanol and deionized water to ultrasonically clean the ground and polished titanium plate samples respectively. Acetone is used for ultrasonic cleaning for 5 minutes to 30 minutes, absolute ethanol is used for ultrasonic cleaning for 5 minutes to 30 minutes, and deionized water is used for ultrasonic cleaning. 5min to 30min, then dry in an oven at a temperature of 40°C to 60°C for 30min to 2h to obtain a pr...

specific Embodiment approach 2

[0028] Embodiment 2: This embodiment differs from Embodiment 1 in that the titanium plate sample described in step 1 is TA2 titanium alloy, TA3 titanium alloy, TA4 titanium alloy or TC4 titanium alloy. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the electrolytic solution containing sodium nitrate described in step 2 is solvent with deionized water, with sodium silicate, calcium acetate, calcium dihydrogen phosphate , EDTA-2Na (disodium ethylenediaminetetraacetic acid), sodium hydroxide and sodium nitrate are solutes; and the concentration of sodium silicate in the electrolyte containing sodium nitrate is 5g / L~8g / L, calcium acetate The concentration of calcium dihydrogen phosphate is 6g / L~10g / L, the concentration of calcium dihydrogen phosphate is 5g / L~8g / L, the concentration of EDTA-2Na (disodium ethylenediaminetetraacetic acid) is 10g / L~20g / L, hydrogen The concentration of sodium oxide is 10g / L-15g / L, and the concentration of sodium nitrate is 3g / L-15g / L. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com