A kind of silicon carbon composite material and preparation method thereof, lithium ion battery

A silicon-carbon composite material, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of volume effect, capacity decay, pulverization, etc. of silicon-based negative electrode materials that are not fundamentally solved, and achieve improvement. Rate Capability, Enhanced Conductivity, Effect of Enhanced Conductivity and Rate Capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

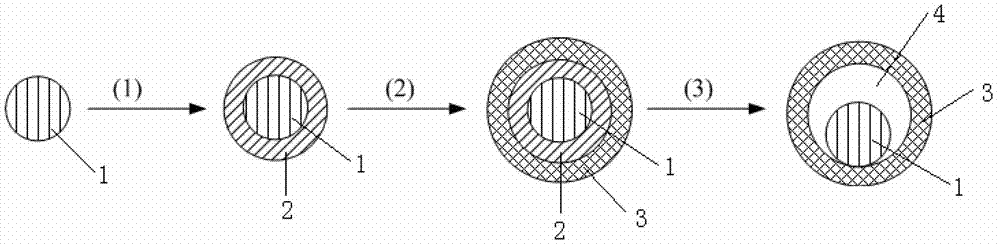

[0035] This embodiment provides a method for preparing a silicon-carbon composite material, comprising the following steps:

[0036] (1) setting a transition layer on the silicon-based material to obtain the silicon-based material covered by the transition layer;

[0037] (2) Coating carbon on the silicon-based material covered by the transition layer to obtain a carbon-transition layer-silicon-based composite material;

[0038] (3) The transition layer is removed to obtain a silicon-carbon composite material.

[0039] In the above preparation method, a transition layer is provided outside the silicon-based material, carbon is coated on the outside of the transition layer, and the transition layer between the silicon-based material and carbon is removed to obtain a silicon-carbon composite material with a certain distance between the silicon base and the carbon. of pores. Setting the thickness of the transition layer according to the theoretical microscopic volume expansion ...

Embodiment 2

[0043] This embodiment provides a method for preparing a silicon-carbon composite material, comprising the following steps:

[0044] (1) Prepare an aqueous solution of calcium chloride, then add silicon powder, and stir to make the silicon powder evenly dispersed in the aqueous solution of calcium chloride. Under stirring state, in above-mentioned mixture, add the aqueous solution of sodium carbonate dropwise, calcium carbonate is precipitated on silicon powder, and the aqueous solution of sodium carbonate added is excessive 2% to guarantee the calcium ion precipitation in the aqueous solution completely, after standing for 2 hours, Suction filtration or centrifugation, washing 3 times, and drying to obtain a silicon-based material coated with calcium carbonate, wherein the mass ratio of the silicon-based material to calcium carbonate is 1:3.34.

[0045] (2) Add the calcium carbonate-coated silicon-based material and sucrose into a planetary ball mill, and ball mill at a speed...

Embodiment 3

[0056] This embodiment provides a method for preparing a silicon-carbon composite material, comprising the following steps:

[0057] (1) Prepare an aqueous solution of barium nitrate, then add silicon monoxide (the theoretical specific capacity of silicon silicide is about 1200mAh / g), and stir to make silicon monoxide evenly dispersed in the aqueous solution of barium nitrate. In the stirring state, add the aqueous solution of sodium carbonate dropwise to the above mixture, precipitate barium carbonate on the silicon monoxide, and add the aqueous solution of sodium carbonate in excess of 2% to ensure that the barium ion in the aqueous solution is completely precipitated, after standing for 2 hours , filtered or centrifuged, washed three times, and dried to obtain a silicon monoxide material coated with barium carbonate, wherein the mass ratio of silicon monoxide to barium carbonate is 1:6.5.

[0058] (2) After the barium carbonate-coated silicon monoxide material and the polya...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com