Fast hydrogen producing agent

A hydrogen generator, a fast technology, applied in the production of hydrogen and other directions, can solve the problems of easy agglomeration of aluminum particles, high cost of hydrogen generator, surface oxidation effect, etc. The effect of the ball milling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

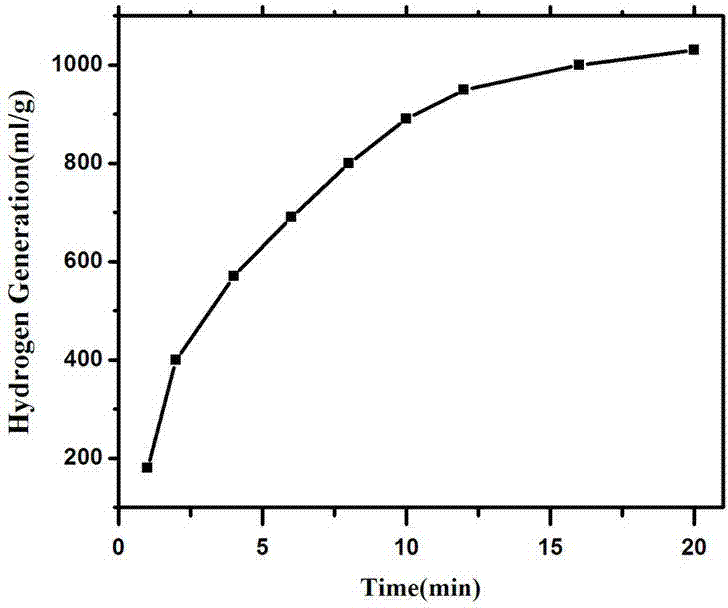

Embodiment 1

[0036] The rapid hydrogen production agent is composed of aluminum, magnesium, calcium oxide, low melting point metals, abrasives, adhesives and antioxidants. Among them, the mass fraction of magnesium is 5%, the mass fraction of calcium oxide is 30%, the mass fraction of low-melting point metal is 2%, the mass fraction of friction agent is 3%, the mass fraction of adhesive is 2%, and the mass fraction of antioxidant is The mass fraction is 3%, and the rest is aluminum.

[0037] Among them, the low melting point metal is gallium indium tin zinc alloy (mass percentage is 61% gallium, 25% indium, 13% tin, 1% zinc), the friction agent is calcium carbonate, the binder is sodium alginate, and the antioxidant is phosphoric acid Ethylenediamine.

[0038] The hydrogen-generating agent uses a ball milling process to process the solid component into a powder. The ball milling time is 5 hours, and the diameter of the powder is 100 μm. Finally, the ball-milled powder is pressed and mold...

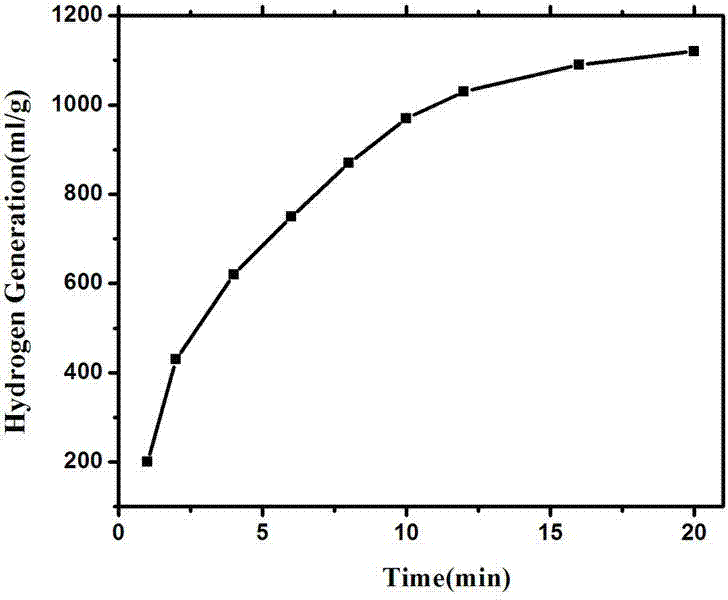

Embodiment 2

[0041] The rapid hydrogen production agent is composed of aluminum, magnesium, calcium oxide, low melting point metals, abrasives, adhesives and antioxidants. Among them, the mass fraction of magnesium is 8%, the mass fraction of calcium oxide is 20%, the mass fraction of low-melting point metal is 5%, the mass fraction of friction agent is 5%, the mass fraction of binder is 3%, and the mass fraction of antioxidant is The mass fraction is 2%, and the rest is aluminum.

[0042]Among them, the low melting point metal is gallium indium tin zinc alloy (mass percentage is 61% gallium, 25% indium, 13% tin, 1% zinc), the friction agent is sodium chloride, the binder is starch, and the antioxidant is sulfurous acid iron.

[0043] The hydrogen-generating agent uses a ball milling process to process the solid components into powder. The ball milling time is 15 hours, and the powder diameter is 30 μm. Finally, the ball-milled powder is pressed and molded in a mold.

[0044] When in us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com