Recovery method for waste of dry glue

A technology of waste recycling and dry glue, applied in the direction of plastic recycling, recycling technology, wet spinning method, etc., can solve the problems of increasing production costs, poor recovery of dry glue waste, and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1: Recycling of Dry Rubber Waste and Preparation of Latex Silk

[0051] Pulverization: the dry rubber waste is pulverized by an ultrafine pulverizer to obtain a powder;

[0052] Stirring: Mix the obtained powder with petroleum ether in a weight ratio of 1:2 and place it in a 13-ton iron tank coated with an isolation layer and internally coated with an anti-rust layer, and stir;

[0053] Centrifugation: solid-liquid separation is achieved through a centrifuge;

[0054] Collect the liquid obtained by centrifugation, and add ammonia water with a volume ratio of 0.1% to keep fresh to obtain regenerated glue;

[0055] Regenerated glue: natural rubber latex is mixed in a volume ratio of 1:2 to obtain a mixture.

[0056] Process steps:

[0057]Mixing and stirring: stabilizer (potassium hydroxide, 0.6 parts by weight), accelerator (MZ: 2-mercaptobenzothiazole zinc salt, 1 parts by weight and BZ: dibutyldithioamino Zinc formate, 0.5 parts by weight), vulcanizing ag...

Embodiment 2

[0063] Embodiment 2: Dry rubber waste recycling and latex preparation

[0064] Pulverization: the dry rubber waste is pulverized by an ultrafine pulverizer to obtain a powder;

[0065] Stirring: Mix the obtained powder with petroleum ether in a weight ratio of 1:2 and place it in a 13-ton iron tank coated with an isolation layer and internally coated with an anti-rust layer, and stir;

[0066] Centrifugation: solid-liquid separation is achieved through a centrifuge;

[0067] Collect the liquid obtained by centrifugation, and add ammonia water with a volume ratio of 0.1% to keep fresh to obtain regenerated glue;

[0068] Regenerated glue: natural rubber latex is mixed in a volume ratio of 1:2 to obtain a mixture.

[0069] Process steps:

[0070] Mixing and stirring: stabilizer (potassium hydroxide, 0.9 parts by weight), accelerator (MZ: 2-mercaptobenzothiazole zinc salt, 1 parts by weight and BZ: dibutyldithioamino Zinc formate, 0.5 parts by weight), vulcanizing agent (sul...

Embodiment 3

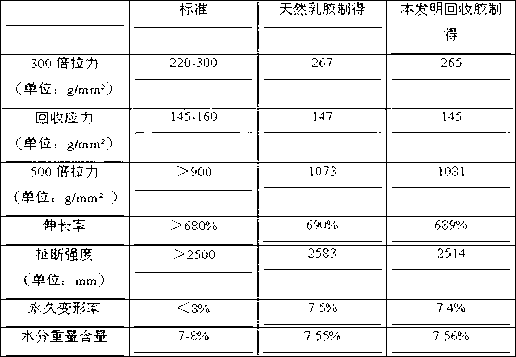

[0076] Example 3: Effect Test

[0077] See HG / T 2487-2011 for the detection method and HG / T 2889-2011 for the standard.

[0078] The test results are shown in Table 1

[0079]

[0080] As can be seen from Table 1, each physical parameter of the latex silk that the latex silk that the present invention obtains is made with natural latex is almost the same, all within the standard range, fully illustrates that the latex that the present invention makes meets the standard, satisfies the requirement of technology need.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com